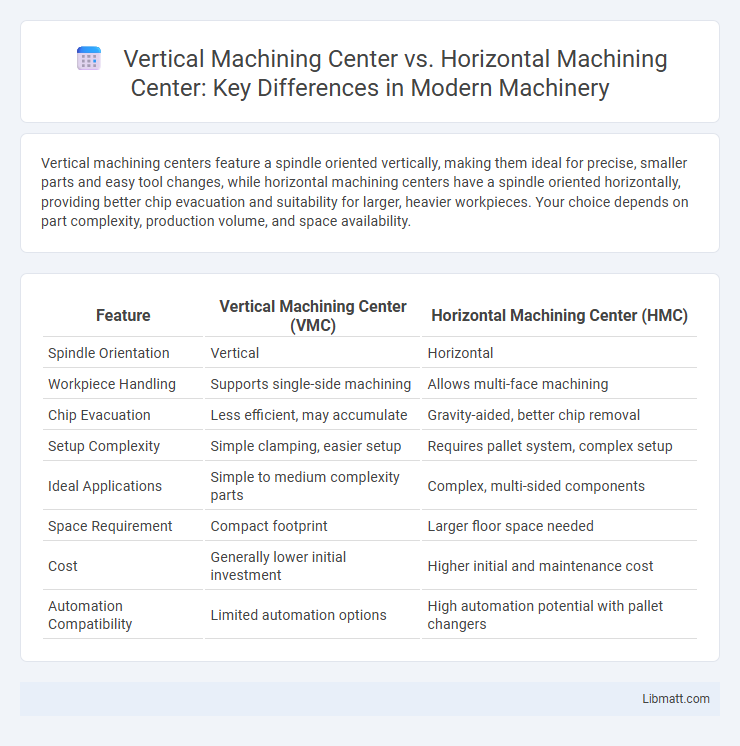

Vertical machining centers feature a spindle oriented vertically, making them ideal for precise, smaller parts and easy tool changes, while horizontal machining centers have a spindle oriented horizontally, providing better chip evacuation and suitability for larger, heavier workpieces. Your choice depends on part complexity, production volume, and space availability.

Table of Comparison

| Feature | Vertical Machining Center (VMC) | Horizontal Machining Center (HMC) |

|---|---|---|

| Spindle Orientation | Vertical | Horizontal |

| Workpiece Handling | Supports single-side machining | Allows multi-face machining |

| Chip Evacuation | Less efficient, may accumulate | Gravity-aided, better chip removal |

| Setup Complexity | Simple clamping, easier setup | Requires pallet system, complex setup |

| Ideal Applications | Simple to medium complexity parts | Complex, multi-sided components |

| Space Requirement | Compact footprint | Larger floor space needed |

| Cost | Generally lower initial investment | Higher initial and maintenance cost |

| Automation Compatibility | Limited automation options | High automation potential with pallet changers |

Introduction to Vertical and Horizontal Machining Centers

Vertical machining centers feature a vertically oriented spindle, making them ideal for precision work on smaller to medium-sized parts, particularly in industries like aerospace and automotive manufacturing. Horizontal machining centers have a horizontally oriented spindle, providing superior chip evacuation and better suited for machining larger, heavier parts with complex geometries. Both types utilize CNC technology for precise control, but vertical centers excel in multi-axis milling, while horizontal centers offer advantages in stability and production efficiency.

Defining Vertical Machining Centers (VMCs)

Vertical Machining Centers (VMCs) feature a vertically oriented spindle positioned above the worktable, ideal for precise milling, drilling, and cutting operations on flat or complex surfaces. Their design allows for greater accessibility and ease in loading and unloading workpieces, making them suitable for a wide range of materials and industries. Your choice of a VMC can enhance production efficiency and accuracy, especially for parts requiring high precision and complex geometries.

Overview of Horizontal Machining Centers (HMCs)

Horizontal Machining Centers (HMCs) feature a horizontally oriented spindle allowing for better chip evacuation and improved machining of deep or complex parts. These centers excel in high-volume production environments, offering increased tool life and reduced cycle times due to efficient coolant flow and gravity-assisted chip removal. HMCs are predominantly used for heavy-duty cutting operations and multi-sided machining, enhancing precision and throughput in automotive, aerospace, and heavy machinery industries.

Key Differences Between VMCs and HMCs

Vertical machining centers (VMCs) feature a vertically oriented spindle ideal for small to medium-sized parts with less complex geometries, while horizontal machining centers (HMCs) have a horizontally oriented spindle suited for larger, heavier workpieces requiring multi-sided machining. VMCs typically offer easier setup and accessibility, whereas HMCs provide enhanced chip evacuation and higher efficiency in automated production environments. The choice between VMC and HMC heavily depends on part size, production volume, and machining complexity.

Advantages of Vertical Machining Centers

Vertical machining centers offer superior versatility for complex part geometries and easier tool accessibility due to their vertical spindle orientation. They typically require less floor space and are more cost-effective to install and maintain compared to horizontal machining centers. The vertical design enhances chip evacuation through gravity, improving machining efficiency and reducing downtime.

Benefits of Horizontal Machining Centers

Horizontal machining centers offer superior chip evacuation due to gravity, enhancing cutting efficiency and tool life while reducing downtime. Their design allows multiple side machining, enabling simultaneous operations and increased productivity for complex parts. You benefit from improved stability and rigidity in horizontal setups, resulting in higher precision and better surface finishes on workpieces.

Common Applications and Industry Usage

Vertical machining centers (VMCs) are widely used in industries such as automotive, aerospace, and general manufacturing for tasks like milling, drilling, and boring on smaller or medium-sized parts with complex geometries. Horizontal machining centers (HMCs) excel in heavy-duty machining and high-volume production environments, often found in automotive and heavy equipment manufacturing, where they handle larger, heavier components with multi-sided machining. Both VMCs and HMCs play crucial roles in precision manufacturing, but VMCs are favored for flexibility and smaller batch sizes, whereas HMCs are optimized for efficiency in mass production and simultaneous multi-axis machining.

Factors to Consider When Choosing Between VMC and HMC

When choosing between a Vertical Machining Center (VMC) and a Horizontal Machining Center (HMC), consider factors such as part complexity, production volume, and workspace size. VMCs are ideal for simpler parts and smaller footprints, while HMCs offer superior chip evacuation and are better suited for high-volume, multi-sided machining. Your selection should align with precision requirements, automation compatibility, and maintenance capabilities to optimize manufacturing efficiency.

Cost and Maintenance Considerations

Vertical machining centers typically have lower initial costs and simpler maintenance due to easier access to the spindle and tooling, making them ideal for small to medium production runs. Horizontal machining centers often require higher investment but offer better chip evacuation and tool life, leading to reduced long-term maintenance expenses and improved operational efficiency in high-volume manufacturing. Factoring in energy consumption, tooling costs, and machine downtime further emphasizes the cost-effectiveness of vertical centers for flexibility, while horizontal centers excel in heavy-duty, continuous production environments.

Conclusion: Selecting the Right Machining Center for Your Needs

Vertical machining centers excel in precision and ease of tool changes, making them ideal for complex, multi-surface parts with smaller footprints. Horizontal machining centers offer superior chip evacuation and increased rigidity, suited for high-volume production and heavy-duty milling tasks. Choosing between them depends on factors like workpiece size, production volume, and specific machining requirements to maximize efficiency and cost-effectiveness.

Vertical machining center vs horizontal machining center Infographic

libmatt.com

libmatt.com