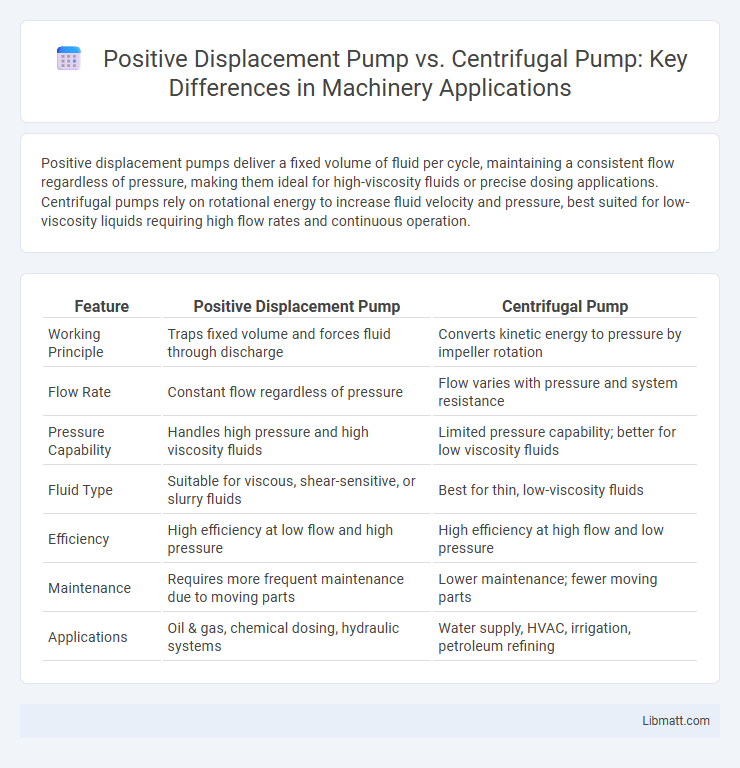

Positive displacement pumps deliver a fixed volume of fluid per cycle, maintaining a consistent flow regardless of pressure, making them ideal for high-viscosity fluids or precise dosing applications. Centrifugal pumps rely on rotational energy to increase fluid velocity and pressure, best suited for low-viscosity liquids requiring high flow rates and continuous operation.

Table of Comparison

| Feature | Positive Displacement Pump | Centrifugal Pump |

|---|---|---|

| Working Principle | Traps fixed volume and forces fluid through discharge | Converts kinetic energy to pressure by impeller rotation |

| Flow Rate | Constant flow regardless of pressure | Flow varies with pressure and system resistance |

| Pressure Capability | Handles high pressure and high viscosity fluids | Limited pressure capability; better for low viscosity fluids |

| Fluid Type | Suitable for viscous, shear-sensitive, or slurry fluids | Best for thin, low-viscosity fluids |

| Efficiency | High efficiency at low flow and high pressure | High efficiency at high flow and low pressure |

| Maintenance | Requires more frequent maintenance due to moving parts | Lower maintenance; fewer moving parts |

| Applications | Oil & gas, chemical dosing, hydraulic systems | Water supply, HVAC, irrigation, petroleum refining |

Introduction to Positive Displacement and Centrifugal Pumps

Positive displacement pumps operate by trapping a fixed volume of fluid and mechanically forcing it through the discharge, making them ideal for high-viscosity fluids and precise flow control. Centrifugal pumps use rotational energy from a spinning impeller to increase fluid velocity and convert it to flow, excelling in applications requiring high flow rates with low viscosity liquids. Understanding the fundamental mechanisms of each pump type is crucial for selecting the right system based on fluid properties and performance requirements.

Operating Principles: How Each Pump Works

Positive displacement pumps operate by trapping a fixed volume of fluid and forcing it through the discharge outlet, maintaining a consistent flow regardless of pressure changes. Centrifugal pumps use a rotating impeller to impart kinetic energy to the fluid, converting it into pressure to move the fluid outward and through the pump casing. Understanding your system's pressure and flow requirements helps determine whether the steady flow of a positive displacement pump or the variable flow of a centrifugal pump is more suitable.

Key Differences in Pump Design

Positive displacement pumps feature a fixed volume chamber that moves fluid by trapping and displacing it with each cycle, ensuring constant flow regardless of pressure changes. Centrifugal pumps utilize an impeller to impart kinetic energy to fluids, converting velocity to flow and pressure, resulting in variable flow dependent on system resistance. The key design difference lies in how positive displacement pumps maintain flow through mechanical trapping, while centrifugal pumps rely on dynamic fluid motion and velocity energy conversion.

Flow Characteristics and Performance

Positive displacement pumps deliver a fixed volume of fluid per cycle, providing consistent flow regardless of pressure changes, making them ideal for high-viscosity or precise dosing applications. Centrifugal pumps generate flow by converting rotational kinetic energy to fluid velocity, resulting in variable flow rates that decrease as system pressure rises, suitable for low-viscosity fluids and high-flow scenarios. Performance of positive displacement pumps remains stable under varying conditions, while centrifugal pumps exhibit nonlinear performance curves sensitive to system head and flow resistance.

Efficiency: Which Pump Performs Better?

Positive displacement pumps generally offer higher efficiency than centrifugal pumps at low flow rates and high pressures due to their ability to deliver a fixed volume per cycle with minimal slip. Centrifugal pumps tend to perform more efficiently at higher flow rates and lower pressure conditions because their energy transfer mechanism suits such applications better. Selecting the optimal pump depends on the specific operating range, with positive displacement pumps excelling in precise, high-pressure environments and centrifugal pumps favored for large-volume, low-viscosity fluid movement.

Suitable Applications for Each Pump Type

Positive displacement pumps are ideal for applications requiring precise flow rates and handling viscous fluids, such as in chemical dosing, oil transfer, and food processing. Centrifugal pumps excel in high-flow, low-viscosity fluid scenarios like water supply, HVAC systems, and wastewater treatment. Your choice depends on the need for consistent flow and pressure (positive displacement) versus high flow volumes with variable pressure (centrifugal).

Handling Viscous and Non-Viscous Fluids

Positive displacement pumps excel at handling high-viscosity fluids by moving a fixed amount of fluid per cycle, ensuring consistent flow regardless of pressure changes. Centrifugal pumps are more effective with low-viscosity, non-viscous fluids as they rely on centrifugal force to create flow, which decreases significantly with increased fluid viscosity. Understanding your fluid's viscosity is crucial to selecting the right pump to optimize performance and efficiency.

Maintenance Requirements and Longevity

Positive displacement pumps require more frequent maintenance due to their tighter tolerances and moving parts that experience higher wear, but they often offer longer service life when properly maintained. Centrifugal pumps have simpler designs with fewer moving parts, resulting in lower routine maintenance needs, yet their lifespan can be shorter under harsh operating conditions. Understanding your system's maintenance capacity and operational demands will help you choose the pump that ensures optimal longevity and performance.

Cost Considerations and Budgeting

Positive displacement pumps generally have higher initial costs due to their complex design and precision components, but they offer better efficiency at low flow rates, reducing long-term energy expenses. Centrifugal pumps are typically more affordable upfront and easier to maintain, making them suitable for applications with high flow rates and lower pressure requirements. Understanding your system's specific flow and pressure demands helps you budget effectively by balancing initial investment against operational and maintenance costs.

Choosing the Right Pump for Your Needs

Positive displacement pumps deliver a fixed volume of fluid with each cycle, making them ideal for high-viscosity liquids or precise dosing applications. Centrifugal pumps are better suited for low-viscosity fluids requiring high flow rates, such as water transfer or cooling systems. Understanding your fluid properties, flow rate, and pressure requirements is essential for selecting the right pump for your needs.

Positive displacement pump vs centrifugal pump Infographic

libmatt.com

libmatt.com