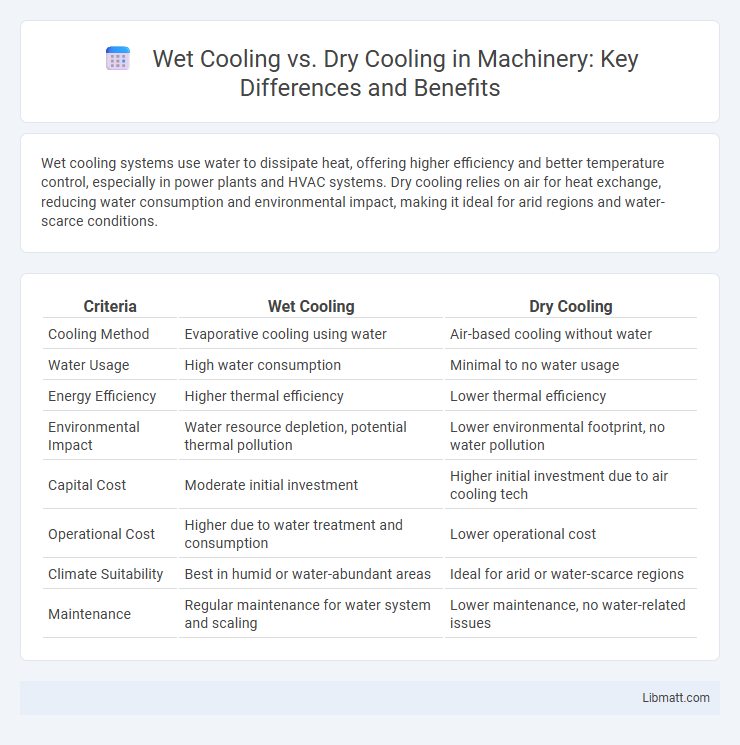

Wet cooling systems use water to dissipate heat, offering higher efficiency and better temperature control, especially in power plants and HVAC systems. Dry cooling relies on air for heat exchange, reducing water consumption and environmental impact, making it ideal for arid regions and water-scarce conditions.

Table of Comparison

| Criteria | Wet Cooling | Dry Cooling |

|---|---|---|

| Cooling Method | Evaporative cooling using water | Air-based cooling without water |

| Water Usage | High water consumption | Minimal to no water usage |

| Energy Efficiency | Higher thermal efficiency | Lower thermal efficiency |

| Environmental Impact | Water resource depletion, potential thermal pollution | Lower environmental footprint, no water pollution |

| Capital Cost | Moderate initial investment | Higher initial investment due to air cooling tech |

| Operational Cost | Higher due to water treatment and consumption | Lower operational cost |

| Climate Suitability | Best in humid or water-abundant areas | Ideal for arid or water-scarce regions |

| Maintenance | Regular maintenance for water system and scaling | Lower maintenance, no water-related issues |

Introduction to Wet and Dry Cooling Systems

Wet cooling systems use evaporative cooling, where water absorbs heat from industrial processes or power plants and releases it into the atmosphere, achieving high thermal efficiency. Dry cooling systems rely on air-cooled heat exchangers to transfer heat, minimizing water consumption but often resulting in higher operational temperatures. Both systems serve critical roles in thermal management, with wet cooling favored for efficiency and dry cooling prioritized in water-scarce environments.

How Wet Cooling Works

Wet cooling works by transferring heat from industrial processes or power plants to water, which absorbs the heat and evaporates into the atmosphere, effectively removing excess heat. This method relies on cooling towers or ponds where hot water is sprayed or circulated, allowing evaporation to cool the remaining water before it is recirculated. Your system's efficiency depends on factors like ambient temperature, humidity, and water availability, making wet cooling highly effective in areas with abundant water resources.

Understanding Dry Cooling Technology

Dry cooling technology uses air instead of water to condense steam in power plants, significantly reducing water consumption and minimizing environmental impact. This method employs large finned tube heat exchangers where ambient air flows over the tubes to dissipate heat, making it ideal for arid regions with limited water resources. Although dry cooling systems have higher initial investment and slightly lower thermal efficiency compared to wet cooling, they provide sustainable and eco-friendly solutions for modern thermal power generation.

Efficiency Comparison: Wet vs Dry Cooling

Wet cooling systems typically achieve higher thermal efficiency due to their superior heat rejection capacity, often reaching cooling efficiencies above 90%. Dry cooling, although less efficient with typical efficiencies around 70-85%, offers significant water conservation benefits, making it ideal for arid regions. The efficiency trade-off between wet and dry cooling directly influences power plant performance, operational costs, and environmental impact.

Water Usage and Environmental Impact

Wet cooling systems consume significantly more water than dry cooling methods, often using millions of gallons per day, which can strain local water resources and impact aquatic ecosystems. Dry cooling minimizes water usage by relying on air instead of water for heat dissipation, reducing the risk of water contamination and thermal pollution. Your choice between wet and dry cooling affects not only operational water consumption but also the broader environmental footprint, including potential impacts on local biodiversity and water availability.

Cost Considerations and Economic Analysis

Wet cooling systems generally have lower initial capital costs compared to dry cooling systems due to simpler equipment and infrastructure requirements. Operating expenses for wet cooling, however, tend to be higher because of water consumption, treatment, and potential regulatory compliance costs. Economic analysis often favors wet cooling in regions with abundant water supply, while dry cooling is more cost-effective in arid areas despite its higher upfront investment.

Climate Suitability for Each Cooling Method

Wet cooling systems excel in humid or water-abundant regions due to their high efficiency in heat dissipation through evaporation, making them ideal for tropical and coastal climates. Dry cooling methods are better suited for arid or water-scarce environments, as they rely on air rather than water evaporation, minimizing water consumption while maintaining operational performance. Selecting the appropriate cooling technology based on regional climate and water availability significantly impacts thermal power plant efficiency and environmental sustainability.

Maintenance Requirements and Longevity

Wet cooling systems generally require more frequent maintenance due to issues like scaling, fouling, and corrosion from water treatment chemicals, which can reduce component lifespan. Dry cooling systems experience lower maintenance demands since they avoid water-related problems, but their heat exchange surfaces must be kept clean to ensure efficiency. The longevity of dry cooling components is typically higher because they are less exposed to corrosive elements, whereas wet cooling equipment may need earlier replacement or refurbishment due to water-induced wear.

Case Studies: Industry Applications

Wet cooling systems in power plants demonstrate high efficiency and are widely used in coastal regions where abundant water resources are available, as shown in the Case Study of the Diablo Canyon Nuclear Power Plant. Dry cooling technology, utilized in arid environments like the Mojave Solar Project, significantly reduces water consumption but can experience reduced thermal performance during extreme heat. Industry applications highlight that choosing between wet and dry cooling depends on water availability, environmental regulations, and cooling efficiency requirements.

Future Trends in Cooling Technologies

Future trends in cooling technologies emphasize the shift toward hybrid systems that combine the water-saving benefits of dry cooling with the efficiency of wet cooling. Innovations in advanced materials and intelligent controls are enhancing thermal performance and reducing water consumption, crucial for sustainable operations in arid regions. Research in phase-change materials and sensor-driven optimization is driving improvements in the energy efficiency and environmental footprint of power plant cooling systems.

Wet cooling vs dry cooling Infographic

libmatt.com

libmatt.com