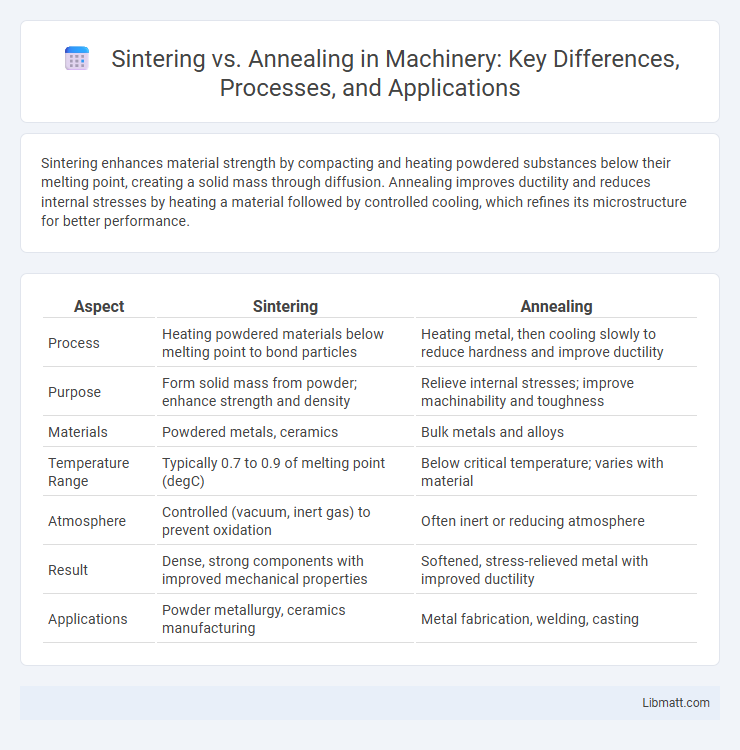

Sintering enhances material strength by compacting and heating powdered substances below their melting point, creating a solid mass through diffusion. Annealing improves ductility and reduces internal stresses by heating a material followed by controlled cooling, which refines its microstructure for better performance.

Table of Comparison

| Aspect | Sintering | Annealing |

|---|---|---|

| Process | Heating powdered materials below melting point to bond particles | Heating metal, then cooling slowly to reduce hardness and improve ductility |

| Purpose | Form solid mass from powder; enhance strength and density | Relieve internal stresses; improve machinability and toughness |

| Materials | Powdered metals, ceramics | Bulk metals and alloys |

| Temperature Range | Typically 0.7 to 0.9 of melting point (degC) | Below critical temperature; varies with material |

| Atmosphere | Controlled (vacuum, inert gas) to prevent oxidation | Often inert or reducing atmosphere |

| Result | Dense, strong components with improved mechanical properties | Softened, stress-relieved metal with improved ductility |

| Applications | Powder metallurgy, ceramics manufacturing | Metal fabrication, welding, casting |

Introduction to Sintering and Annealing

Sintering is a high-temperature process that fuses powdered materials into a solid mass through heat below the melting point, enhancing mechanical strength and density. Annealing involves heating metals or alloys to specific temperatures followed by controlled cooling to reduce hardness, relieve internal stresses, and improve ductility. Both processes are essential in materials engineering for optimizing microstructure and mechanical properties in manufacturing and metalworking.

Defining Sintering: Process and Principles

Sintering is a thermal process that compacts and fuses powdered materials into a solid mass by heating them below their melting point, enhancing material strength and structural integrity. This process relies on atomic diffusion, where particles bond at contact points through heat-induced mass transfer, resulting in densification without liquefaction. Understanding sintering principles helps you optimize manufacturing techniques for ceramics, metals, and composites with tailored mechanical properties.

Understanding Annealing: Process and Mechanisms

Annealing involves heating a material to a specific temperature, maintaining it, and then cooling it slowly to alter its microstructure, reduce internal stresses, and improve ductility. This process allows atoms to diffuse and realign, promoting recrystallization and reducing dislocation densities. Your metals become softer and more workable after annealing, making it essential for materials requiring enhanced mechanical properties.

Key Differences Between Sintering and Annealing

Sintering involves heating powdered materials below their melting points to bond particles into a solid mass, enhancing material density and strength for applications like metal and ceramic manufacturing. Annealing, on the other hand, heats solid metals to reduce hardness, relieve internal stresses, and improve ductility, commonly used to restore metal workability after deformation. The key differences lie in sintering's role in material fabrication from powders versus annealing's function in altering mechanical properties of already solid metals.

Applications of Sintering in Material Science

Sintering is widely applied in material science for producing advanced ceramics, metal parts, and powder metallurgy components, enabling the creation of complex shapes with enhanced mechanical properties. This process densifies powdered materials at temperatures below their melting points, improving strength, wear resistance, and thermal stability in applications such as automotive, aerospace, and electronics industries. Your innovations in manufacturing benefit from sintering by achieving precise control over microstructure and material performance unattainable through annealing alone.

Common Uses of Annealing in Industry

Annealing is widely used in the manufacturing of metals and alloys to improve ductility, reduce hardness, and relieve internal stresses caused by machining or cold working. In the steel industry, annealing enhances machinability and prepares materials for further processing such as forming or welding. It is also critical in the production of glass and semiconductor wafers, where controlled heating refines crystal structure and eliminates defects.

Advantages and Disadvantages of Sintering

Sintering offers the advantage of producing complex shapes with high strength and improved material density without melting the base material, making it energy-efficient and suitable for powder metallurgy. However, it has limitations such as potential porosity, requiring precise temperature control and longer processing times compared to annealing. Your choice between sintering and annealing depends on the desired mechanical properties, material type, and manufacturing complexity.

Pros and Cons of Annealing

Annealing improves metal ductility and reduces internal stresses, enhancing machinability and structural uniformity, but it can be time-consuming and energy-intensive compared to sintering. This heat treatment process also risks grain growth that may reduce mechanical strength if not carefully controlled. Your choice depends on whether improved toughness or dimensional accuracy is prioritized over production speed and cost.

Factors Influencing the Choice Between Sintering and Annealing

Temperature, material composition, and desired mechanical properties are key factors influencing the choice between sintering and annealing. Sintering is preferred for powder metallurgy with high-density and strength requirements, while annealing optimizes ductility and reduces internal stresses in metals through controlled heating and cooling. Your decision should consider application-specific goals such as grain structure, hardness, and production efficiency.

Conclusion: Selecting the Right Heat Treatment Technique

Sintering is ideal for consolidating powdered materials into solid forms with enhanced mechanical properties, while annealing focuses on relieving internal stresses and improving ductility in metals. Your choice depends on whether you need to densify materials or modify their microstructure for better toughness and machinability. Understanding the specific goals of your heat treatment ensures optimal performance and durability of the final product.

Sintering vs annealing Infographic

libmatt.com

libmatt.com