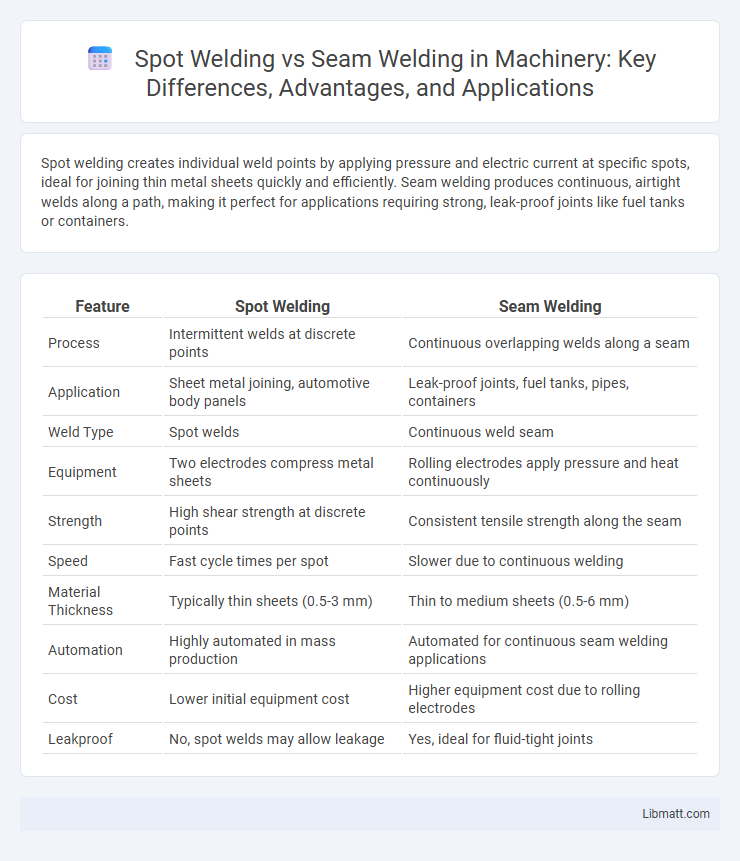

Spot welding creates individual weld points by applying pressure and electric current at specific spots, ideal for joining thin metal sheets quickly and efficiently. Seam welding produces continuous, airtight welds along a path, making it perfect for applications requiring strong, leak-proof joints like fuel tanks or containers.

Table of Comparison

| Feature | Spot Welding | Seam Welding |

|---|---|---|

| Process | Intermittent welds at discrete points | Continuous overlapping welds along a seam |

| Application | Sheet metal joining, automotive body panels | Leak-proof joints, fuel tanks, pipes, containers |

| Weld Type | Spot welds | Continuous weld seam |

| Equipment | Two electrodes compress metal sheets | Rolling electrodes apply pressure and heat continuously |

| Strength | High shear strength at discrete points | Consistent tensile strength along the seam |

| Speed | Fast cycle times per spot | Slower due to continuous welding |

| Material Thickness | Typically thin sheets (0.5-3 mm) | Thin to medium sheets (0.5-6 mm) |

| Automation | Highly automated in mass production | Automated for continuous seam welding applications |

| Cost | Lower initial equipment cost | Higher equipment cost due to rolling electrodes |

| Leakproof | No, spot welds may allow leakage | Yes, ideal for fluid-tight joints |

Introduction to Spot Welding and Seam Welding

Spot welding and seam welding are resistance welding techniques primarily used to join metal sheets by applying pressure and electric current. Spot welding creates discrete weld points by clamping metals with electrodes at specific spots, ideal for quick assembly in automotive and manufacturing industries. Seam welding produces continuous, leak-tight welds by rolling electrodes along the joint, commonly used in fuel tanks, pipes, and metal containers.

Fundamental Differences Between Spot and Seam Welding

Spot welding joins metal sheets at discrete points by applying pressure and electric current through electrodes, creating localized welds ideal for quick assembly of thin metals. Seam welding produces continuous welds along a joint by rotating wheel electrodes that apply heat and pressure, forming airtight and watertight seals commonly used in tubular or sheet metal fabrication. The fundamental difference lies in spot welding creating individual fusion points, whereas seam welding generates a continuous, overlapping weld bead.

Working Principles of Spot Welding

Spot welding operates by applying pressure and passing an electric current through two overlapping metal sheets, generating heat due to electrical resistance that melts the metal and forms a weld nugget at the contact point. The process is highly effective for joining thin sheets of metal, commonly used in automotive and manufacturing industries. Its precision in localized heating minimizes distortion and allows for rapid, repeatable welds.

Working Principles of Seam Welding

Seam welding operates by applying continuous electrical current and pressure through rotating wheel electrodes that move along overlapping metal sheets, creating a uniform series of welds. This process uses resistance heat generated at the interface of the metals, ensuring a tight, leak-proof joint ideal for applications such as fuel tanks and automotive panels. Precise control of parameters like current, pressure, and electrode speed is critical to maintain consistent seam quality and prevent metal distortion.

Equipment and Setup Comparison

Spot welding uses a pair of copper electrodes to clamp and apply resistance heat at discrete points, requiring minimal setup with portable machines ideal for small-scale or repair tasks. Seam welding utilizes rotating wheel electrodes that produce continuous welds along joints, demanding more complex equipment with precise alignment and control systems for automotive or manufacturing applications. The setup for seam welding involves conveyor systems and synchronized electrode pressure, offering higher consistency but increased initial investment compared to the simpler spot welding apparatus.

Applications of Spot Welding in Industry

Spot welding is widely used in the automotive industry for joining sheet metal components due to its speed and efficiency. It is essential in manufacturing appliances, such as refrigerators and washing machines, where consistent, strong welds are required on thin metal sheets. The aerospace sector also relies on spot welding to assemble lightweight structures with precision and reliability.

Applications of Seam Welding in Industry

Seam welding is extensively utilized in the automotive industry for manufacturing fuel tanks and exhaust systems due to its ability to create continuous, airtight joints. This technique is also prominent in producing metal packaging such as cans and drums, where durability and leak-proof seals are essential. You benefit from seam welding's precision and consistency in industries requiring high-strength, corrosion-resistant seams for sheet metal assemblies.

Advantages and Disadvantages of Spot Welding

Spot welding offers rapid and cost-effective joining of metal sheets with minimal distortion, making it ideal for automotive and manufacturing industries. However, its disadvantages include limited weld size, difficulty in joining thick materials, and potential for weld nugget inconsistencies affecting joint strength. Your choice depends on the application requirements, including material thickness and the need for continuous welds versus discrete points.

Advantages and Disadvantages of Seam Welding

Seam welding offers the advantage of producing continuous, leak-proof joints ideal for applications requiring airtight or watertight seals, such as fuel tanks and metal packaging. Its disadvantages include higher equipment costs and complexity compared to spot welding, as well as limitations in welding thicker materials due to heat concentration along the seam. Seam welding also requires precise control of welding parameters to prevent seam irregularities and maintain consistent weld quality.

Choosing the Right Welding Method: Spot vs Seam

Choosing the right welding method depends on your specific application requirements, with spot welding ideal for joining overlapping metal sheets through concentrated weld points, offering high strength and minimal distortion. Seam welding creates continuous, leak-proof joints by producing a series of overlapping spot welds, making it perfect for applications requiring airtight or watertight seams, such as fuel tanks and pipes. Assess your project's need for strength, durability, and seal integrity to determine whether spot welding or seam welding best suits your manufacturing process.

Spot welding vs seam welding Infographic

libmatt.com

libmatt.com