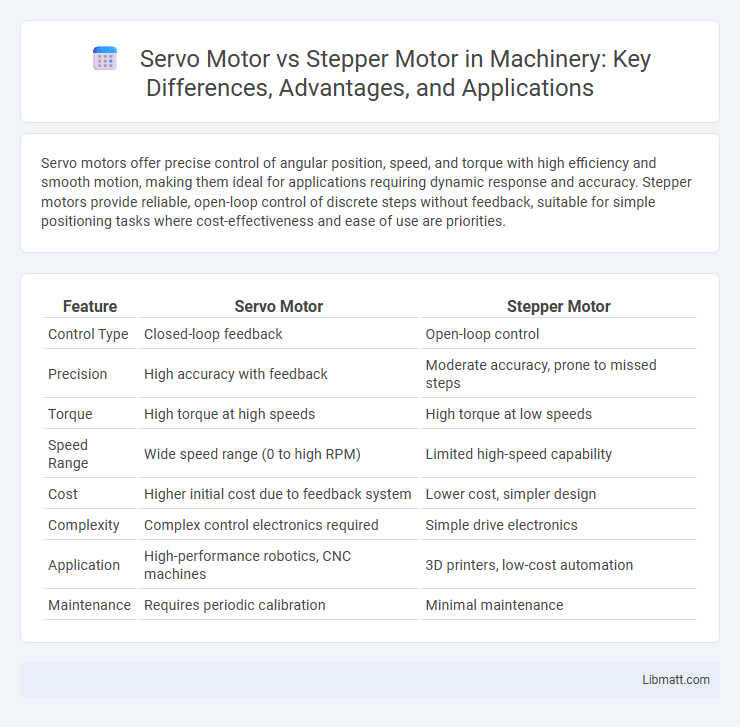

Servo motors offer precise control of angular position, speed, and torque with high efficiency and smooth motion, making them ideal for applications requiring dynamic response and accuracy. Stepper motors provide reliable, open-loop control of discrete steps without feedback, suitable for simple positioning tasks where cost-effectiveness and ease of use are priorities.

Table of Comparison

| Feature | Servo Motor | Stepper Motor |

|---|---|---|

| Control Type | Closed-loop feedback | Open-loop control |

| Precision | High accuracy with feedback | Moderate accuracy, prone to missed steps |

| Torque | High torque at high speeds | High torque at low speeds |

| Speed Range | Wide speed range (0 to high RPM) | Limited high-speed capability |

| Cost | Higher initial cost due to feedback system | Lower cost, simpler design |

| Complexity | Complex control electronics required | Simple drive electronics |

| Application | High-performance robotics, CNC machines | 3D printers, low-cost automation |

| Maintenance | Requires periodic calibration | Minimal maintenance |

Introduction to Servo and Stepper Motors

Servo motors provide precise control of angular or linear position, velocity, and acceleration through feedback systems, making them ideal for applications requiring high accuracy and dynamic response. Stepper motors move in discrete steps with open-loop control, offering simplicity and reliability in positioning tasks without the need for feedback mechanisms. Understanding the fundamental operational differences between these motors helps you select the best solution for your motion control needs.

Basic Working Principles

Servo motors use feedback systems with encoders to precisely control angular position, velocity, and acceleration, enabling smooth, continuous rotation. Stepper motors divide a full rotation into equal steps, moving in discrete increments without feedback, which simplifies control but limits resolution and torque. Your choice depends on whether precise positioning with dynamic response (servo) or simple, open-loop control with fixed steps (stepper) better suits your application.

Key Differences Between Servo and Stepper Motors

Servo motors provide precise control of angular position, velocity, and torque through feedback systems, making them ideal for applications requiring high accuracy and dynamic response. Stepper motors operate by dividing full rotation into equal steps without feedback, offering simpler control and reliability for low to medium precision tasks. Understanding these key differences helps you select the right motor type based on performance requirements and application complexity.

Precision and Accuracy Comparison

Servo motors deliver higher precision and accuracy through closed-loop feedback systems that continuously adjust position based on real-time data, enabling precise control even under varying loads. Stepper motors operate on open-loop control, achieving accuracy by moving in fixed increments or steps, but they may experience missed steps or resonance issues that reduce positioning accuracy. For applications demanding fine resolution and consistent accuracy, servo motors outperform stepper motors, particularly in dynamic or high-speed environments.

Speed and Torque Characteristics

Servo motors deliver high speed and precise torque control, making them ideal for applications requiring rapid acceleration and deceleration. Stepper motors offer consistent torque at low speeds but their torque decreases significantly as speed increases, limiting their effectiveness in high-speed tasks. Your choice between the two should depend on whether consistent torque at varying speeds or precise speed control is more critical for your application.

Control Systems and Feedback Mechanisms

Servo motors utilize closed-loop control systems with continuous feedback from encoders or resolvers, enabling precise position, speed, and torque regulation. Stepper motors typically operate on open-loop control systems without direct feedback, relying on fixed step increments for positioning, which may lead to missed steps under high load conditions. Your choice depends on the required accuracy and complexity of feedback needed for optimal performance in your application.

Applications in Industry

Servo motors are widely used in robotics, CNC machinery, and automated manufacturing due to their high precision, speed control, and torque capabilities, making them ideal for applications requiring smooth and dynamic movements. Stepper motors excel in applications like 3D printers, conveyor systems, and packaging machines where precise positioning and repeatability are critical but closed-loop control is not essential. Industries benefit from servo motors in high-performance tasks demanding feedback systems, while stepper motors are preferred for cost-effective, open-loop control solutions with moderate accuracy requirements.

Pros and Cons of Servo Motors

Servo motors provide high precision, excellent torque at high speeds, and smooth motion control, making them ideal for applications requiring accurate positioning. They offer closed-loop feedback systems that enhance performance but tend to be more expensive and complex compared to stepper motors. Your choice of a servo motor depends on the need for precision, speed, and dynamic response versus budget and simplicity.

Pros and Cons of Stepper Motors

Stepper motors offer precise position control and are ideal for applications requiring accurate incremental movements, such as 3D printers and CNC machines. They are cost-effective, have a simple design, and do not require feedback systems, but tend to produce more noise, generate less torque at high speeds, and can suffer from resonance issues. Your choice depends on balancing these pros and cons against the specific motion control requirements of your project.

Choosing the Right Motor for Your Application

Servo motors offer precise control, high torque, and smooth operation ideal for applications requiring speed variation and accurate positioning. Stepper motors provide reliable, cost-effective performance with simpler control systems, perfect for tasks needing consistent, incremental movements. Evaluating your application's speed, torque, and control requirements will help you select the motor that maximizes efficiency and performance.

Servo motor vs stepper motor Infographic

libmatt.com

libmatt.com