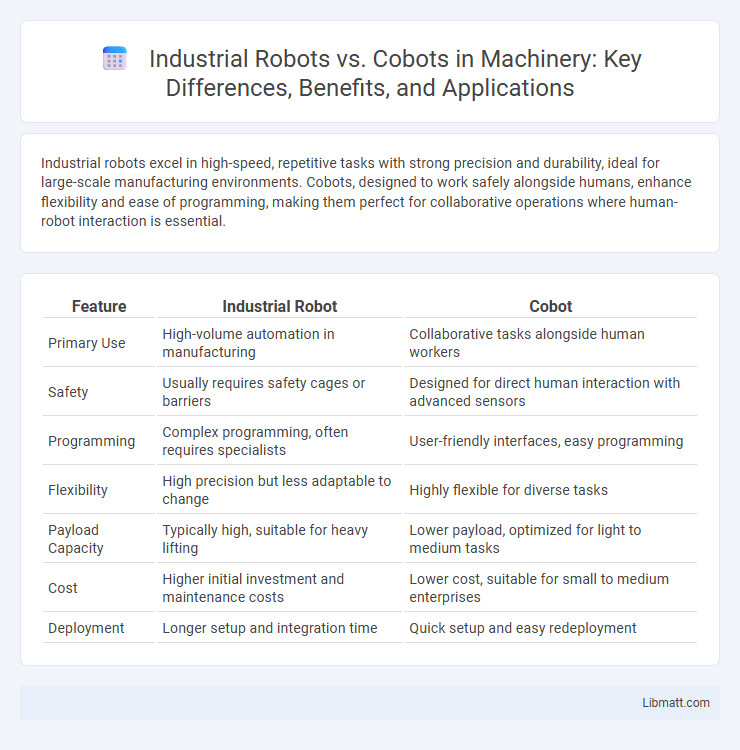

Industrial robots excel in high-speed, repetitive tasks with strong precision and durability, ideal for large-scale manufacturing environments. Cobots, designed to work safely alongside humans, enhance flexibility and ease of programming, making them perfect for collaborative operations where human-robot interaction is essential.

Table of Comparison

| Feature | Industrial Robot | Cobot |

|---|---|---|

| Primary Use | High-volume automation in manufacturing | Collaborative tasks alongside human workers |

| Safety | Usually requires safety cages or barriers | Designed for direct human interaction with advanced sensors |

| Programming | Complex programming, often requires specialists | User-friendly interfaces, easy programming |

| Flexibility | High precision but less adaptable to change | Highly flexible for diverse tasks |

| Payload Capacity | Typically high, suitable for heavy lifting | Lower payload, optimized for light to medium tasks |

| Cost | Higher initial investment and maintenance costs | Lower cost, suitable for small to medium enterprises |

| Deployment | Longer setup and integration time | Quick setup and easy redeployment |

Introduction to Industrial Robots and Cobots

Industrial robots are programmable machines designed for automated tasks in manufacturing environments, excelling in high-speed, high-precision operations such as welding, assembly, and material handling. Cobots, or collaborative robots, are engineered to work alongside human operators safely, with advanced sensors and adaptable programming enabling direct interaction without safety cages. The key distinction lies in their application focus: industrial robots optimize throughput and efficiency in isolated settings, while cobots enhance flexibility and human-robot collaboration on the factory floor.

Key Differences Between Industrial Robots and Cobots

Industrial robots operate autonomously and are designed for repetitive, high-volume tasks in manufacturing, requiring safety cages due to their high-speed, high-power operation. Cobots, or collaborative robots, work alongside humans with built-in sensors and safety features to enable direct human-robot interaction without physical barriers. The key differences lie in their design purpose, safety requirements, and flexibility in adapting to diverse, dynamic environments.

Safety Features: Industrial Robots vs Cobots

Industrial robots are typically enclosed or require safety barriers to protect workers due to their high-speed, high-force operations, while cobots are designed with integrated safety features such as force sensors and speed limits that allow them to work safely alongside humans without extensive guarding. Cobots' advanced collision detection and responsive shutdown mechanisms minimize injury risks, making them ideal for collaborative tasks in shared workspaces. Understanding these safety distinctions can help you choose the right automation solution that balances productivity with workplace protection.

Flexibility and Adaptability in Manufacturing

Industrial robots offer high precision and speed but are often limited by rigid programming and fixed automation tasks, making them less adaptable to sudden changes in manufacturing processes. Cobots, designed for close human collaboration, provide enhanced flexibility through easy reprogramming and can quickly adapt to diverse tasks and product variations on the production line. Their ability to safely interact with operators while adjusting to dynamic environments significantly improves manufacturing efficiency and responsiveness.

Installation and Programming Requirements

Industrial robots require complex installation processes and specialized programming skills due to their size, power, and operational complexity, often involving dedicated safety measures and extensive setup times. Cobots feature easier installation and user-friendly programming interfaces, typically allowing your team to deploy and adjust tasks with minimal technical expertise and shorter downtime. This streamlined setup makes cobots ideal for flexible applications where rapid integration and collaborative operation with human workers are essential.

Cost Comparison: Investment and ROI

Industrial robots generally require a higher initial investment, often ranging from $50,000 to $150,000 per unit, due to their complexity and heavy-duty capabilities, while cobots typically cost between $20,000 and $40,000, making them more accessible for small to medium enterprises. ROI for industrial robots can take longer to realize because of integration, programming, and maintenance expenses, whereas cobots offer quicker ROI by enabling direct collaboration with human workers, reducing downtime and training costs. Cost efficiency improves with cobots in flexible production environments, while industrial robots deliver superior ROI in high-volume, repetitive tasks requiring precision and speed.

Applications and Industry Use-Cases

Industrial robots excel in high-volume manufacturing, automotive assembly, and heavy material handling due to their precision and strength. Cobots are designed for close human collaboration, making them ideal for small-batch production, quality inspection, and light-duty tasks in electronics and healthcare industries. Your choice depends on the need for automation scale, safety requirements, and workforce interaction in specific industrial applications.

Productivity and Efficiency Analysis

Industrial robots excel in high-volume, repetitive tasks with precise speed, significantly boosting productivity in large-scale manufacturing. Cobots, designed for safe human-robot collaboration, enhance efficiency by allowing flexible automation and reducing downtime through easier programming and integration. Analyzing productivity metrics reveals industrial robots achieve higher throughput in structured environments, while cobots optimize workflow adaptability and operational efficiency in dynamic settings.

Collaborative Work Environments

Industrial robots operate autonomously in isolated environments designed for high-speed, repetitive tasks, ensuring safety through physical barriers. Cobots are engineered for direct interaction with human workers, equipped with sensors and advanced safety features to enable seamless collaboration on assembly lines or packaging. This integration of cobots enhances productivity and flexibility in collaborative work environments without compromising worker safety.

Future Trends in Automation: Robots and Cobots

Future trends in automation emphasize increased collaboration between industrial robots and cobots, with cobots designed to safely work alongside human operators enhancing flexibility and productivity. Industrial robots continue to advance in precision and speed for large-scale manufacturing, while cobots integrate AI and sensor technologies for adaptive, real-time responses in diverse environments. Your operations can benefit from combining these technologies to optimize efficiency and accommodate evolving automation demands.

Industrial robot vs cobot Infographic

libmatt.com

libmatt.com