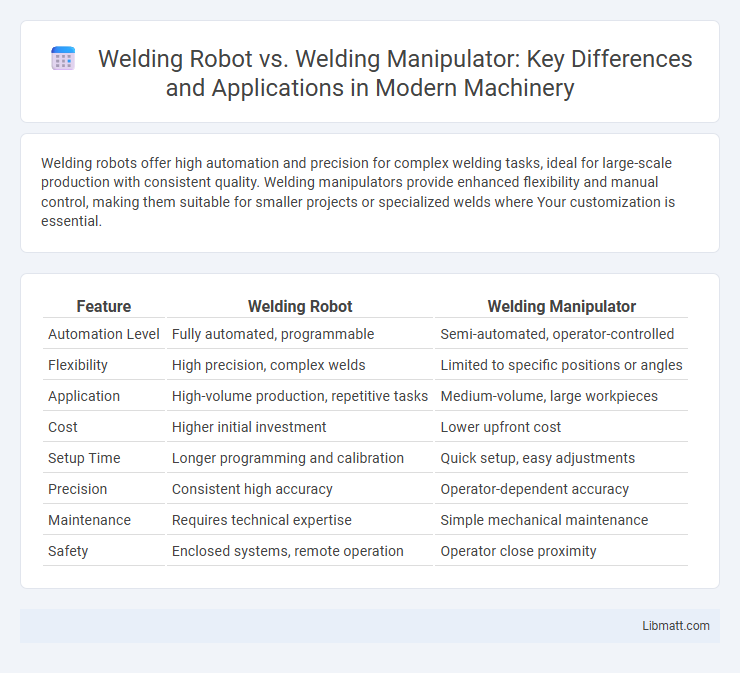

Welding robots offer high automation and precision for complex welding tasks, ideal for large-scale production with consistent quality. Welding manipulators provide enhanced flexibility and manual control, making them suitable for smaller projects or specialized welds where Your customization is essential.

Table of Comparison

| Feature | Welding Robot | Welding Manipulator |

|---|---|---|

| Automation Level | Fully automated, programmable | Semi-automated, operator-controlled |

| Flexibility | High precision, complex welds | Limited to specific positions or angles |

| Application | High-volume production, repetitive tasks | Medium-volume, large workpieces |

| Cost | Higher initial investment | Lower upfront cost |

| Setup Time | Longer programming and calibration | Quick setup, easy adjustments |

| Precision | Consistent high accuracy | Operator-dependent accuracy |

| Maintenance | Requires technical expertise | Simple mechanical maintenance |

| Safety | Enclosed systems, remote operation | Operator close proximity |

Introduction to Welding Robots and Welding Manipulators

Welding robots are automated machines designed for precise, repeatable welding tasks in industrial environments, enhancing productivity and consistency. Welding manipulators are mechanical devices that position the workpiece or welding torch, enabling manual or semi-automated welding with improved control over complex geometries. Both technologies optimize welding processes, but robots offer higher automation levels while manipulators provide flexible handling for varied welding applications.

Key Differences Between Welding Robots and Welding Manipulators

Welding robots are automated machines programmed to perform complex welding tasks with high precision and flexibility across various applications, while welding manipulators are mechanical devices designed to position and rotate workpieces to facilitate manual or semi-automatic welding. Robots integrate advanced sensors and AI for adaptive operations, offering higher productivity and consistency compared to manipulators that primarily serve as positioning aids. The key differences lie in automation level, control complexity, and application adaptability, with welding robots being prominent in high-volume, repetitive tasks and manipulators suited for large or heavy components requiring stable positioning.

Core Functions and Applications

Welding robots offer fully automated, programmable solutions ideal for high-precision tasks in mass production environments such as automotive manufacturing, ensuring consistent weld quality and increased throughput. Welding manipulators provide flexible, manual or semi-automatic control suited for large, complex workpieces where positioning and operator input are critical, often employed in shipbuilding or heavy equipment fabrication. Your choice depends on the required automation level, production volume, and the complexity of the welding application.

Automation Levels: Robots vs Manipulators

Welding robots offer higher automation levels with advanced programming capabilities, precise movements, and the ability to handle complex weld patterns independently. Welding manipulators provide semi-automated control, requiring more operator input for positioning and movement, suitable for simpler or repetitive tasks. Your choice depends on the desired mix of flexibility, accuracy, and automation efficiency in the welding process.

Precision and Repeatability Comparison

Welding robots offer superior precision and repeatability due to advanced programmable controls and multi-axis movement capabilities, enabling consistent weld quality in complex and high-volume applications. Welding manipulators provide stable positioning and repeatable weld paths mainly in fixed or semi-fixed operations, but they lack the flexibility and fine control of robotic systems. The enhanced sensor integration and automated adjustments in welding robots reduce human error, ensuring higher accuracy and uniform weld seams over extended production runs.

Programming and Operation Complexity

Welding robots require advanced programming skills to create precise automated welding paths using specialized software, making them suitable for complex and high-volume production tasks. Welding manipulators offer simpler operation with manual or semi-automatic control, allowing operators to adjust welding positions without intensive programming knowledge. The difference in programming and operation complexity makes welding robots ideal for repetitive, intricate welds, while manipulators are favored for flexibility and ease of use in less automated environments.

Flexibility and Adaptability in Welding Processes

Welding robots offer superior flexibility and adaptability by automating complex welding tasks across various positions and materials with programmable precision, enabling rapid changes between different welding processes. Welding manipulators provide limited flexibility, primarily enhancing manual welding by stabilizing and precisely positioning the workpiece, but typically require human operation and are less adaptable to diverse welding scenarios. The choice between welding robots and manipulators hinges on production volume and process complexity, where robots excel in high-speed, repetitive manufacturing environments and manipulators support artisanal or small-batch operations.

Cost Analysis: Initial Investment and Maintenance

Welding robots typically require a higher initial investment compared to welding manipulators due to advanced technology and automation capabilities, often ranging from $50,000 to $150,000 depending on complexity and brand. Maintenance costs for welding robots include regular software updates, sensor calibration, and potential robotic arm repairs, averaging 10-15% of the initial investment annually. Welding manipulators have lower upfront costs, generally between $10,000 and $40,000, with simpler mechanical parts that reduce maintenance expenses, usually around 5-8% of their initial cost per year.

Suitability for Industry Sectors

Welding robots excel in high-volume manufacturing sectors such as automotive and aerospace due to their precision, speed, and ability to perform complex welds continuously. Welding manipulators are better suited for industries like shipbuilding, construction, and heavy machinery, where large, bulky workpieces require flexible positioning and manual operator control. Your choice between the two depends on the complexity of tasks and scale of production within your specific industry.

Choosing the Right Solution for Your Welding Needs

Welding robots offer high precision and automation for repetitive and complex welding tasks, ideal for large-scale production environments requiring consistent weld quality and speed. Welding manipulators provide greater flexibility and control for customized or varied welding jobs, allowing operators to handle different positions and angles manually, making them suitable for smaller batches or repair work. Selecting between a welding robot and manipulator depends on factors like production volume, required weld consistency, customization level, and budget constraints.

Welding robot vs welding manipulator Infographic

libmatt.com

libmatt.com