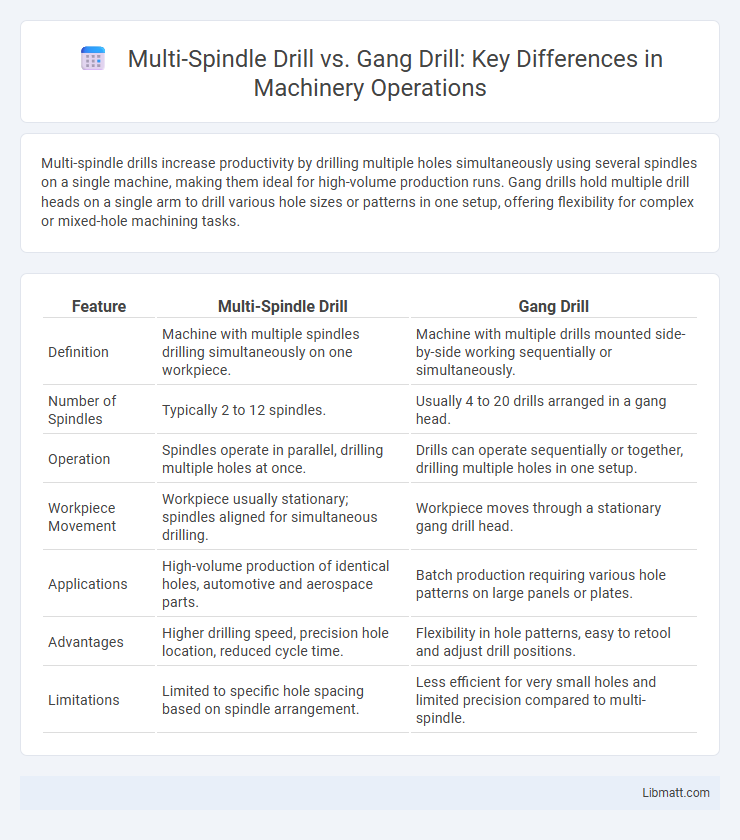

Multi-spindle drills increase productivity by drilling multiple holes simultaneously using several spindles on a single machine, making them ideal for high-volume production runs. Gang drills hold multiple drill heads on a single arm to drill various hole sizes or patterns in one setup, offering flexibility for complex or mixed-hole machining tasks.

Table of Comparison

| Feature | Multi-Spindle Drill | Gang Drill |

|---|---|---|

| Definition | Machine with multiple spindles drilling simultaneously on one workpiece. | Machine with multiple drills mounted side-by-side working sequentially or simultaneously. |

| Number of Spindles | Typically 2 to 12 spindles. | Usually 4 to 20 drills arranged in a gang head. |

| Operation | Spindles operate in parallel, drilling multiple holes at once. | Drills can operate sequentially or together, drilling multiple holes in one setup. |

| Workpiece Movement | Workpiece usually stationary; spindles aligned for simultaneous drilling. | Workpiece moves through a stationary gang drill head. |

| Applications | High-volume production of identical holes, automotive and aerospace parts. | Batch production requiring various hole patterns on large panels or plates. |

| Advantages | Higher drilling speed, precision hole location, reduced cycle time. | Flexibility in hole patterns, easy to retool and adjust drill positions. |

| Limitations | Limited to specific hole spacing based on spindle arrangement. | Less efficient for very small holes and limited precision compared to multi-spindle. |

Introduction to Multi-Spindle Drill and Gang Drill

Multi-spindle drills feature multiple drilling heads mounted on a single spindle, enabling simultaneous drilling of several holes with high precision, primarily used for high-volume production in automotive and aerospace industries. Gang drills consist of several independent drilling units aligned on a common bed, providing flexibility to drill different hole sizes and patterns simultaneously, often favored in manufacturing complex components. Both machines optimize production efficiency but differ in design, operation, and application based on hole uniformity and process complexity.

Key Differences Between Multi-Spindle and Gang Drills

Multi-spindle drills feature multiple spindles arranged on a single head, allowing simultaneous drilling of identical holes, enhancing precision and reducing cycle time in high-volume production. Gang drills consist of several independent spindles mounted in a line on a bed, enabling varied hole placements and sizes without repositioning the workpiece, ideal for medium-volume operations with diverse hole patterns. Key differences include spindle arrangement, flexibility in hole configuration, and typical application scope, with multi-spindle drills favoring uniform, repetitive drilling and gang drills supporting varied, complex drilling tasks.

Design and Construction Comparison

Multi-spindle drills feature multiple spindles mounted on a single frame, allowing simultaneous drilling of several holes with precise synchronization, while gang drills arrange multiple independent spindles in a linear setup, each capable of operating separately. The compact, rigid design of multi-spindle drills enhances accuracy and reduces cycle times for repetitive hole patterns, whereas gang drills offer greater flexibility in handling varied hole sizes and depths due to their individual spindle control. Your choice depends on whether you prioritize high-volume, consistent hole production or adaptable drilling configurations for diverse machining tasks.

Precision and Accuracy in Drilling Operations

Multi-spindle drills offer enhanced precision and accuracy by simultaneously drilling multiple holes with uniform spacing, reducing cumulative errors common in single-spindle setups. Gang drills, while capable of handling diverse hole sizes and types in one setup, may experience slight variations in accuracy due to the independent operation of each spindle. For high-precision drilling operations requiring consistent hole placement, multi-spindle drills provide superior repeatability and tighter tolerance control compared to gang drills.

Productivity and Speed: Multi-Spindle vs Gang Drill

Multi-spindle drills enhance productivity by simultaneously drilling multiple holes with high precision, reducing cycle times significantly compared to single-spindle setups. Gang drills, while capable of performing several operations at once with multiple spindles arranged on a fixed bed, generally offer slower speeds due to limited spindle synchronization and tooling change flexibility. Your manufacturing process benefits most from multi-spindle drills when speed and rapid hole repetition are critical for maximizing output.

Flexibility and Application Scope

Multi-spindle drills offer higher flexibility by allowing simultaneous drilling of multiple holes with adjustable spindle arrangements, ideal for varied hole patterns and different workpiece sizes. Gang drills provide greater efficiency for high-volume production runs with fixed spindle setups, best suited for consistent repetitive drilling tasks on uniform materials. You should choose a multi-spindle drill when job variability and quick setup changes are critical, while a gang drill excels in mass production environments requiring precision and speed.

Cost Considerations and ROI Analysis

Multi-spindle drills typically involve higher initial capital investment due to their complex mechanics but offer faster cycle times and reduced labor costs, enhancing long-term ROI for high-volume production. Gang drills have lower upfront costs and simpler maintenance, making them suitable for smaller batch sizes with less intensive precision demands; however, slower throughput may limit their cost efficiency in large-scale operations. Evaluating ROI requires balancing upfront expenses against throughput, labor savings, and maintenance requirements, with multi-spindle drills proving more cost-effective in high-demand manufacturing environments.

Maintenance and Durability Factors

Multi-spindle drills feature individual spindles that simplify maintenance by allowing targeted repairs and replacements, enhancing overall machine uptime. Gang drills, with their fixed spindle arrangement, often require more extensive maintenance procedures, which can increase downtime but benefit from a more rigid structure that provides long-term durability. Understanding these maintenance and durability factors helps you choose the ideal drilling solution for your production needs, balancing efficiency and equipment longevity.

Best Use Cases for Multi-Spindle and Gang Drills

Multi-spindle drills excel in high-volume production environments where multiple holes must be drilled simultaneously with consistent precision, making them ideal for automotive and aerospace manufacturing. Gang drills are best suited for medium-to-large batch production requiring varied hole sizes in workpieces, commonly used in general machining and metal fabrication shops. Both machines enhance efficiency, but multi-spindle drills provide faster cycle times, while gang drills offer greater versatility in hole patterns and sizes.

Choosing the Right Drill for Your Manufacturing Needs

Multi-spindle drills offer simultaneous drilling with multiple cutting heads, ideal for high-volume production requiring precision and speed. Gang drills feature several individual spindles arranged in a row, allowing flexible tool changes and adaptable operations for varied hole patterns. Your choice depends on production scale, hole complexity, and the balance between flexibility and throughput efficiency in your manufacturing process.

Multi-spindle drill vs gang drill Infographic

libmatt.com

libmatt.com