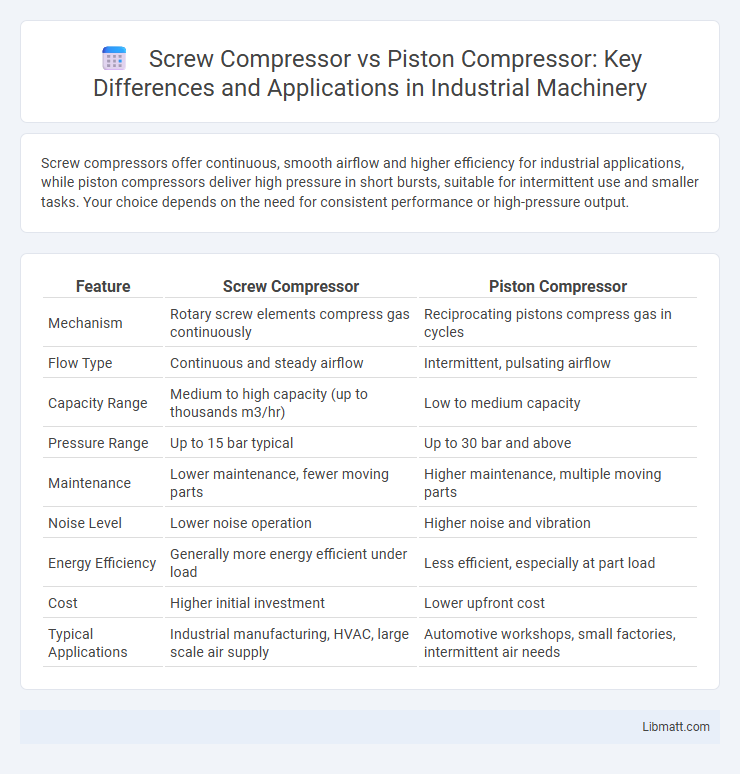

Screw compressors offer continuous, smooth airflow and higher efficiency for industrial applications, while piston compressors deliver high pressure in short bursts, suitable for intermittent use and smaller tasks. Your choice depends on the need for consistent performance or high-pressure output.

Table of Comparison

| Feature | Screw Compressor | Piston Compressor |

|---|---|---|

| Mechanism | Rotary screw elements compress gas continuously | Reciprocating pistons compress gas in cycles |

| Flow Type | Continuous and steady airflow | Intermittent, pulsating airflow |

| Capacity Range | Medium to high capacity (up to thousands m3/hr) | Low to medium capacity |

| Pressure Range | Up to 15 bar typical | Up to 30 bar and above |

| Maintenance | Lower maintenance, fewer moving parts | Higher maintenance, multiple moving parts |

| Noise Level | Lower noise operation | Higher noise and vibration |

| Energy Efficiency | Generally more energy efficient under load | Less efficient, especially at part load |

| Cost | Higher initial investment | Lower upfront cost |

| Typical Applications | Industrial manufacturing, HVAC, large scale air supply | Automotive workshops, small factories, intermittent air needs |

Introduction to Screw and Piston Compressors

Screw compressors utilize twin helical rotors to compress air steadily and efficiently, ideal for continuous industrial applications requiring high volume output. Piston compressors, also known as reciprocating compressors, operate by a piston moving within a cylinder to compress air in cycles, providing high pressure suitable for intermittent heavy-duty use. Your choice between these compressors depends on factors like desired pressure, volume, and application type, influencing energy consumption and maintenance needs.

How Screw Compressors Work

Screw compressors operate using two interlocking helical rotors that trap and compress air as it moves through the casing, providing a continuous flow of compressed gas. The rotors rotate in opposite directions, reducing the volume of trapped air and increasing pressure without pulsations common in piston compressors. This design delivers efficient, reliable performance in industrial applications requiring steady air supply and lower maintenance compared to piston-type compressors.

How Piston Compressors Work

Piston compressors operate by using a reciprocating piston inside a cylinder to compress air or gas through a suction and compression stroke cycle. The piston moves downward to draw in air through an intake valve, then moves upward to compress the air and push it out through a discharge valve. Your choice between screw and piston compressors depends on factors like pressure requirements, efficiency, and maintenance needs, with piston compressors typically favored for high-pressure, low-capacity applications.

Key Differences Between Screw and Piston Compressors

Screw compressors offer continuous airflow with lower vibration and noise levels compared to piston compressors, which produce intermittent airflow through reciprocating motion. Screw compressors are ideal for large-scale industrial applications requiring consistent pressure, while piston compressors excel in high-pressure, low-volume tasks due to their ability to generate higher compression ratios. Maintenance complexity also differs, as screw compressors typically require less frequent servicing compared to the more mechanically intensive piston compressors.

Efficiency Comparison: Screw vs Piston Compressors

Screw compressors generally offer higher efficiency than piston compressors, especially in continuous operation and high-capacity applications, due to their rotary design minimizing energy loss and mechanical wear. Piston compressors tend to have lower initial costs but experience greater efficiency drops under partial load conditions and require more maintenance. Selecting a screw compressor can optimize Your energy consumption and reduce operational costs in industrial settings.

Maintenance Requirements

Screw compressors generally require less frequent maintenance compared to piston compressors due to fewer moving parts and continuous rotary motion, which reduces wear and tear. Piston compressors demand regular inspection of valves, piston rings, and cylinders to prevent leakage and ensure efficient operation. You can minimize downtime and repair costs by selecting a screw compressor for applications prioritizing low maintenance requirements.

Cost Analysis and Investment Considerations

Screw compressors generally have a higher initial investment cost compared to piston compressors due to their complex design and advanced technology. However, screw compressors offer better energy efficiency and lower maintenance expenses, making them more cost-effective over the long term. Your decision should weigh upfront costs against lifecycle savings and intended application requirements.

Applications and Suitable Industries

Screw compressors are widely used in industries requiring continuous, high-capacity air supply such as manufacturing, chemical processing, and food production due to their efficiency and low maintenance needs. Piston compressors are better suited for applications demanding high pressure and intermittent use, including automotive workshops, small-scale construction, and pneumatic tool operation. Understanding your specific industrial application helps determine whether the consistent flow of a screw compressor or the high-pressure pulses of a piston compressor will optimize your system's performance.

Noise, Size, and Space Considerations

Screw compressors operate with significantly lower noise levels compared to piston compressors, making them ideal for environments where noise reduction is crucial. They are more compact and have a smaller footprint, which helps save space in facilities with limited room. When considering your installation, a screw compressor's size and quieter operation may provide better efficiency and comfort than the larger, noisier piston counterpart.

Choosing the Right Compressor for Your Needs

Screw compressors deliver continuous, high-volume airflow ideal for industrial applications requiring steady pressure and low maintenance, while piston compressors offer higher pressure outputs suited for intermittent, high-demand tasks. Consider factors such as airflow requirements, pressure levels, energy efficiency, noise tolerance, and maintenance costs when choosing between screw and piston compressors. Evaluating operational needs and budget constraints ensures selection of the most efficient and cost-effective compressor type.

Screw compressor vs piston compressor Infographic

libmatt.com

libmatt.com