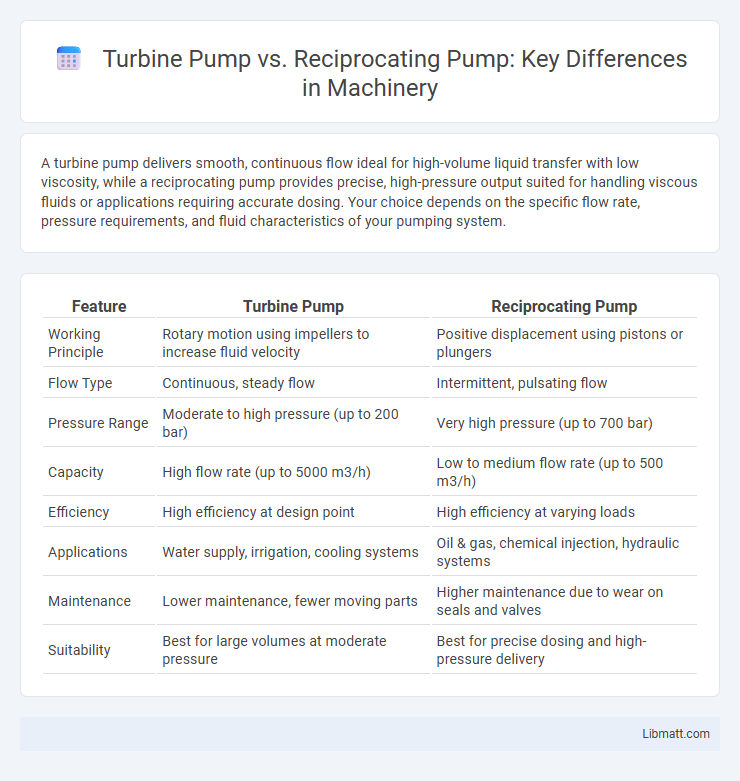

A turbine pump delivers smooth, continuous flow ideal for high-volume liquid transfer with low viscosity, while a reciprocating pump provides precise, high-pressure output suited for handling viscous fluids or applications requiring accurate dosing. Your choice depends on the specific flow rate, pressure requirements, and fluid characteristics of your pumping system.

Table of Comparison

| Feature | Turbine Pump | Reciprocating Pump |

|---|---|---|

| Working Principle | Rotary motion using impellers to increase fluid velocity | Positive displacement using pistons or plungers |

| Flow Type | Continuous, steady flow | Intermittent, pulsating flow |

| Pressure Range | Moderate to high pressure (up to 200 bar) | Very high pressure (up to 700 bar) |

| Capacity | High flow rate (up to 5000 m3/h) | Low to medium flow rate (up to 500 m3/h) |

| Efficiency | High efficiency at design point | High efficiency at varying loads |

| Applications | Water supply, irrigation, cooling systems | Oil & gas, chemical injection, hydraulic systems |

| Maintenance | Lower maintenance, fewer moving parts | Higher maintenance due to wear on seals and valves |

| Suitability | Best for large volumes at moderate pressure | Best for precise dosing and high-pressure delivery |

Introduction to Turbine Pumps and Reciprocating Pumps

Turbine pumps utilize an impeller to convert rotational energy into kinetic energy for fluid movement, making them ideal for high-flow, low-pressure applications such as water supply and irrigation. Reciprocating pumps use a piston or plunger mechanism to create positive displacement, delivering precise, high-pressure flow suitable for applications requiring exact volume control, including hydraulic systems and chemical injection. Understanding the fundamental operational differences between turbine pumps and reciprocating pumps is crucial for selecting the right pump type based on flow rate, pressure requirements, and fluid characteristics.

Working Principles of Turbine Pumps

Turbine pumps operate based on the centrifugal force generated by a rotating impeller, which transfers kinetic energy to the fluid, causing it to move through the pump casing at high velocity. Water or other fluids enter the pump via the eye of the impeller and are accelerated outward through the impeller vanes, resulting in increased pressure and flow rate. Understanding the working principles of turbine pumps helps you select the ideal pump type for high-flow, low-viscosity applications compared to the positive displacement action of reciprocating pumps.

Working Principles of Reciprocating Pumps

Reciprocating pumps operate on the principle of positive displacement, where a piston or plunger moves back and forth within a cylinder to create pressure and move fluid. During the suction stroke, the piston retracts, causing the inlet valve to open and fluid to enter the cylinder, while the discharge valve remains closed. On the discharge stroke, the piston pushes forward, closing the inlet valve and forcing the fluid through the discharge valve into the pipeline.

Key Components: Turbine vs. Reciprocating Pumps

Turbine pumps feature an impeller, casing, and shaft designed for high flow rates and continuous operation, relying on centrifugal force to move fluids efficiently. Reciprocating pumps consist of pistons, cylinders, valves, and a crankshaft, providing precise volumetric flow and high pressure through linear motion. The key difference lies in the turbine pump's rotational mechanism versus the reciprocating pump's back-and-forth piston action, impacting their applications and performance characteristics.

Efficiency Comparison Between Turbine and Reciprocating Pumps

Turbine pumps generally offer higher efficiency for high-flow, low-viscosity fluids due to their continuous rotary action, making them ideal for large-scale water supply and irrigation systems. Reciprocating pumps excel in applications requiring high pressure and precise flow control, though their efficiency decreases at higher flow rates because of increased mechanical losses and pulsation effects. Understanding your specific operational needs can help determine whether the turbine pump's superior hydraulic efficiency or the reciprocating pump's pressure capabilities best suit your system.

Application Areas for Turbine and Reciprocating Pumps

Turbine pumps excel in high-flow, low-viscosity liquid applications such as water supply, irrigation, and HVAC systems, making them ideal for municipal, industrial, and agricultural sectors. Reciprocating pumps are preferred for high-pressure, low-flow scenarios involving viscous fluids or precise dosing, commonly used in oil and gas, chemical processing, and hydraulic systems. Selecting between turbine and reciprocating pumps depends on flow rate, pressure requirements, and fluid characteristics specific to the industrial application.

Maintenance and Reliability

Turbine pumps require less frequent maintenance due to their simplified design and fewer moving parts, resulting in higher reliability in continuous operation. Reciprocating pumps demand more intensive maintenance because of their complex valve assemblies and pistons, which are prone to wear and tear. Reliability in reciprocating pumps can be affected by frequent breakdowns, whereas turbine pumps offer consistent performance with lower downtime.

Performance Characteristics: Flow Rate and Pressure

Turbine pumps typically deliver high flow rates at moderate pressure, making them ideal for applications requiring continuous, steady fluid transfer. Reciprocating pumps produce lower flow rates but generate significantly higher pressures, suitable for situations demanding precision and forceful fluid displacement. The choice between turbine and reciprocating pumps hinges on balancing required flow rate and pressure capabilities according to specific operational needs.

Advantages and Disadvantages

Turbine pumps offer high flow rates and smooth operation with low maintenance, making them ideal for large-volume water transfer and irrigation systems, but they can struggle with high-viscosity fluids and require a stable power source. Reciprocating pumps provide precise flow control and handle high-pressure applications effectively, beneficial for dosing chemicals and oil extraction, though they involve more mechanical wear and higher maintenance costs. Your choice depends on application demands such as flow rate, pressure, fluid type, and maintenance capacity.

Choosing the Right Pump for Your Application

Turbine pumps are ideal for high-flow, low-viscosity fluids and applications requiring continuous operation, such as water supply and irrigation systems. Reciprocating pumps excel in high-pressure, low-flow scenarios and are preferred for precise dosing or transferring viscous liquids in industries like chemical processing and oil. Selecting the right pump depends on your specific application's flow rate, pressure requirements, and fluid characteristics to ensure efficiency and reliability.

Turbine pump vs reciprocating pump Infographic

libmatt.com

libmatt.com