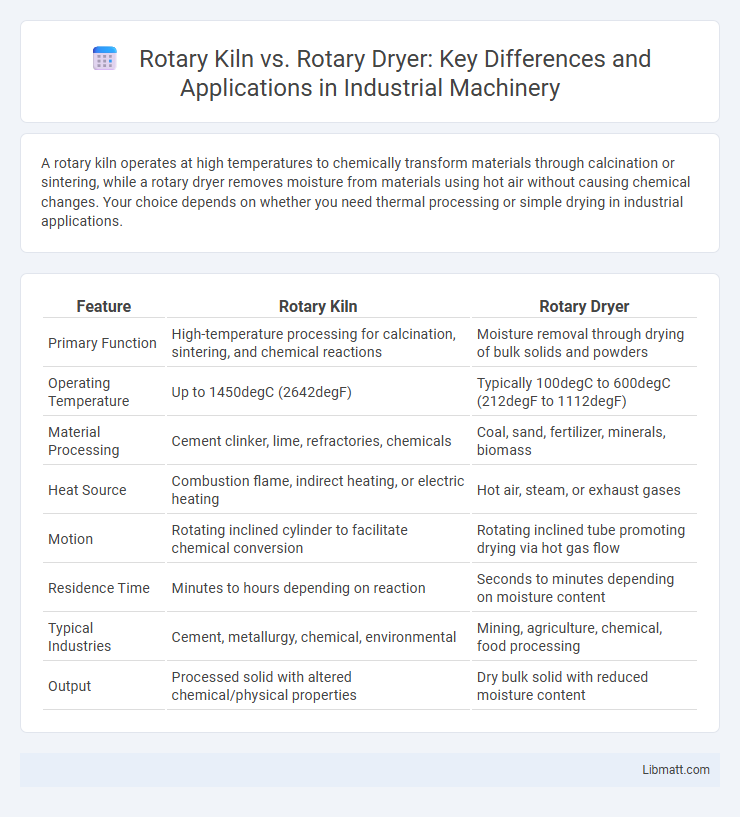

A rotary kiln operates at high temperatures to chemically transform materials through calcination or sintering, while a rotary dryer removes moisture from materials using hot air without causing chemical changes. Your choice depends on whether you need thermal processing or simple drying in industrial applications.

Table of Comparison

| Feature | Rotary Kiln | Rotary Dryer |

|---|---|---|

| Primary Function | High-temperature processing for calcination, sintering, and chemical reactions | Moisture removal through drying of bulk solids and powders |

| Operating Temperature | Up to 1450degC (2642degF) | Typically 100degC to 600degC (212degF to 1112degF) |

| Material Processing | Cement clinker, lime, refractories, chemicals | Coal, sand, fertilizer, minerals, biomass |

| Heat Source | Combustion flame, indirect heating, or electric heating | Hot air, steam, or exhaust gases |

| Motion | Rotating inclined cylinder to facilitate chemical conversion | Rotating inclined tube promoting drying via hot gas flow |

| Residence Time | Minutes to hours depending on reaction | Seconds to minutes depending on moisture content |

| Typical Industries | Cement, metallurgy, chemical, environmental | Mining, agriculture, chemical, food processing |

| Output | Processed solid with altered chemical/physical properties | Dry bulk solid with reduced moisture content |

Introduction to Rotary Kilns and Rotary Dryers

Rotary kilns and rotary dryers are critical industrial equipment designed for thermal processing and material drying, respectively. Rotary kilns operate at high temperatures to induce chemical or physical changes in materials such as cement, lime, and minerals, while rotary dryers use heated air to reduce moisture content in bulk solids. Understanding their distinct functions helps optimize Your production processes in industries like mining, chemical processing, and construction.

Fundamental Differences Between Rotary Kilns and Rotary Dryers

Rotary kilns and rotary dryers differ fundamentally in their primary functions and operational conditions: rotary kilns are designed for high-temperature processing, such as calcination or sintering, where materials undergo chemical transformations, while rotary dryers serve to reduce moisture content through heat application without altering the material's chemical structure. The internal design varies, with rotary kilns featuring refractory linings to withstand extreme heat, and rotary dryers incorporating flights or lifters to enhance drying efficiency by promoting material-to-air contact. Your choice between the two should consider the required thermal treatment, process temperature ranges, and the physical and chemical changes intended for the material.

Design and Structural Comparison

Rotary kilns feature a cylindrical shell with refractory lining designed to withstand high temperatures, enabling thermal processing such as calcination or sintering, while rotary dryers have a simpler construction primarily focused on facilitating heat transfer for moisture removal. The kiln's structure includes a sealing system to contain gases and minimize heat loss, contrasting with the rotary dryer's open-ended or sealed design tailored for drying efficiency. Rotary kilns often incorporate burner assemblies and inclined rotating drums, whereas rotary dryers emphasize internal flights or lifters to enhance material drying through increased surface area exposure.

Primary Functions and Applications

Rotary kilns primarily function as high-temperature processing units for calcining, sintering, and pyroprocessing of materials like cement clinker, lime, and minerals. Rotary dryers are designed to reduce moisture content in bulk solids such as fertilizers, ores, and chemicals by tumbling materials through heated air streams. Their distinct applications stem from rotary kilns facilitating chemical transformation at elevated temperatures, while rotary dryers focus on efficient drying and moisture removal.

Heat Transfer Mechanisms

Rotary kilns primarily use direct contact heat transfer, where hot gases flow through the rotating cylinder, transferring heat to the material by convection and radiation. Rotary dryers rely mainly on convective heat transfer, with hot air passing over the material to remove moisture efficiently. Understanding your process requirements helps determine which heat transfer mechanism--combustion in kilns or airflow in dryers--best suits your thermal treatment needs.

Operational Parameters and Control

Rotary kiln operational parameters emphasize precise temperature control typically ranging from 900degC to 1500degC, essential for chemical reactions in cement or lime production, while rotary dryers operate at lower temperatures around 100degC to 200degC to efficiently reduce moisture content without altering material composition. Control systems in rotary kilns must manage fuel feed, airflow, and rotation speed to ensure consistent calcination, whereas rotary dryers focus on optimizing residence time, airflow, and inlet/outlet temperatures for uniform drying. Your choice between these two should consider these specific operational controls to achieve desired thermal processing outcomes efficiently.

Energy Consumption and Efficiency

Rotary kilns generally consume more energy than rotary dryers due to the higher temperatures required for processes like calcination or pyrolysis, often exceeding 1000degC, whereas rotary dryers operate at lower temperatures around 150-300degC to remove moisture. The thermal efficiency of rotary dryers is typically higher, with energy recovery systems and indirect heating methods reducing fuel consumption, while rotary kilns have challenges in heat retention due to continuous material movement and prolonged residence times. Optimizing insulation, burner design, and process control are critical factors that influence the energy efficiency and operational cost differences between rotary kilns and rotary dryers.

Material Suitability and Processing Capabilities

Rotary kilns are designed for high-temperature processing of materials like cement, lime, and minerals, enabling chemical reactions such as calcination and sintering. Rotary dryers are more suitable for drying bulk solids and powders with heat-sensitive properties, efficiently reducing moisture content without altering the material's chemical structure. Your choice depends on whether the process requires thermal decomposition or simply moisture removal to optimize material handling and product quality.

Maintenance Requirements and Longevity

Rotary kilns require more intensive maintenance due to higher operating temperatures and complex refractory linings that degrade over time, directly impacting their longevity. Rotary dryers operate at lower temperatures, resulting in reduced wear and tear, which typically translates to easier maintenance and longer service life. Proper maintenance tailored to your equipment ensures optimal performance and extended operational lifespan in both rotary kilns and dryers.

Choosing the Right Equipment: Rotary Kiln vs Rotary Dryer

Selecting between a rotary kiln and a rotary dryer depends on the specific industrial requirements such as temperature control, material processing, and end-product quality. Rotary kilns provide high-temperature processing essential for calcination, sintering, or chemical reactions, making them suitable for cement, lime, or metallurgy industries. Rotary dryers excel in moisture removal from bulk solids with lower temperature heat transfer, ideal for agricultural products, minerals, and biomass drying applications.

Rotary kiln vs rotary dryer Infographic

libmatt.com

libmatt.com