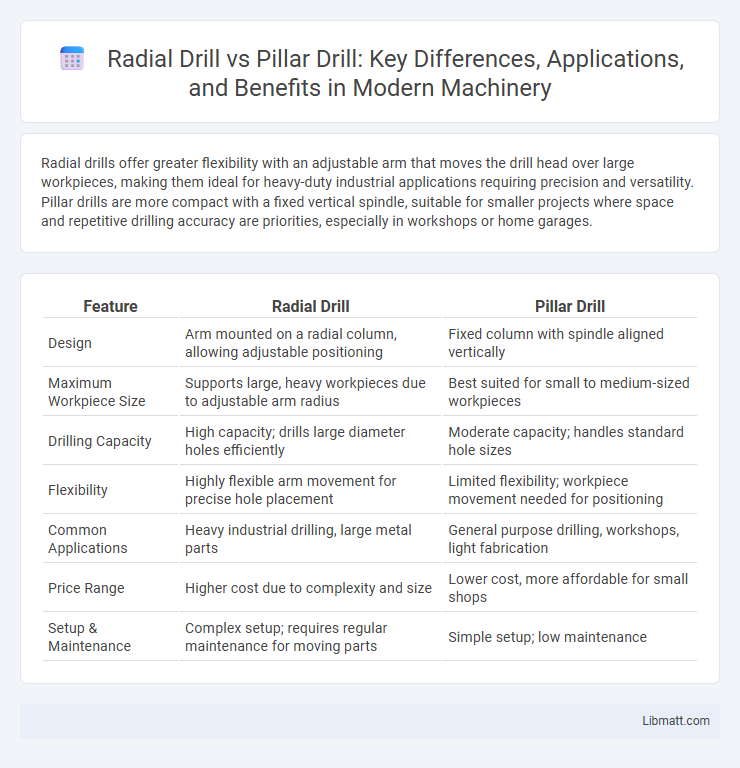

Radial drills offer greater flexibility with an adjustable arm that moves the drill head over large workpieces, making them ideal for heavy-duty industrial applications requiring precision and versatility. Pillar drills are more compact with a fixed vertical spindle, suitable for smaller projects where space and repetitive drilling accuracy are priorities, especially in workshops or home garages.

Table of Comparison

| Feature | Radial Drill | Pillar Drill |

|---|---|---|

| Design | Arm mounted on a radial column, allowing adjustable positioning | Fixed column with spindle aligned vertically |

| Maximum Workpiece Size | Supports large, heavy workpieces due to adjustable arm radius | Best suited for small to medium-sized workpieces |

| Drilling Capacity | High capacity; drills large diameter holes efficiently | Moderate capacity; handles standard hole sizes |

| Flexibility | Highly flexible arm movement for precise hole placement | Limited flexibility; workpiece movement needed for positioning |

| Common Applications | Heavy industrial drilling, large metal parts | General purpose drilling, workshops, light fabrication |

| Price Range | Higher cost due to complexity and size | Lower cost, more affordable for small shops |

| Setup & Maintenance | Complex setup; requires regular maintenance for moving parts | Simple setup; low maintenance |

Introduction to Radial Drill and Pillar Drill

Radial drills feature an adjustable arm that allows drilling at variable distances and angles, making them ideal for large or awkwardly shaped workpieces. Pillar drills have a fixed column and spindle, providing precision and stability for smaller, repetitive drilling tasks. Both machines are essential in metalworking, with radial drills offering flexibility and pillar drills excelling in accuracy and ease of use.

Key Differences Between Radial and Pillar Drills

Radial drills feature an adjustable arm that allows the drill head to move horizontally and vertically, providing greater flexibility for drilling large or awkwardly shaped workpieces. Pillar drills have a fixed drill head mounted on a vertical column, making them ideal for smaller, precise drilling tasks with more rigidity and stability. Radial drills are preferred for heavy-duty industrial applications, whereas pillar drills are commonly used in workshops and small-scale projects.

Structure and Design Comparison

A radial drill features a horizontal arm mounted on a vertical column, allowing the drill head to move both vertically and horizontally for flexible positioning over large workpieces. In contrast, a pillar drill has a fixed head and a stationary column that supports the drill table directly beneath the spindle, offering stability for smaller, precise drilling tasks. The radial drill's design emphasizes versatility and reach, whereas the pillar drill prioritizes rigidity and simplicity in structure.

Working Principle of Radial Drill

The working principle of a radial drill involves a motorized arm that pivots around a vertical column, allowing the drill head to move horizontally and vertically over the workpiece with precision. This design enables drilling operations on large or heavy workpieces without repositioning, enhancing efficiency and accuracy. You benefit from the radial drill's flexible arm movement, which provides greater accessibility compared to the fixed vertical movement of a pillar drill.

Working Principle of Pillar Drill

The working principle of a pillar drill involves a motor-driven spindle that rotates a cutting tool, which is lowered vertically onto the workpiece mounted on a fixed table. This vertical movement is controlled by a feed mechanism, allowing precise drilling depth and pressure. The rigid column and adjustable table support ensure stability and accuracy during the drilling process.

Advantages of Radial Drill Machines

Radial drill machines offer superior flexibility due to their adjustable arm, allowing drilling over large workpieces without repositioning. They provide greater precision and efficiency for heavy-duty tasks, making them ideal for industrial applications requiring versatile and accurate drilling. Your workshop benefits from reduced setup time and enhanced productivity when using a radial drill compared to a pillar drill.

Advantages of Pillar Drill Machines

Pillar drill machines offer precise vertical drilling ideal for metalworking and woodworking, ensuring consistent hole accuracy and depth control. Their robust construction provides stability and reduces vibration, enhancing machining quality and operator safety. Compact design and affordability make pillar drills accessible for small workshops requiring reliable, repeatable drilling tasks.

Applications in Industrial Settings

Radial drills excel in industrial settings requiring flexible, heavy-duty drilling on large or awkwardly shaped workpieces due to their adjustable arm allowing precise positioning. Pillar drills are ideal for repetitive, high-precision vertical drilling tasks on smaller components, ensuring consistent hole accuracy and depth. Your choice between radial and pillar drills depends on the size, complexity, and precision needs of your manufacturing operations.

Choosing the Right Drill for Your Needs

Selecting between a radial drill and a pillar drill depends on your project requirements and workspace. Radial drills offer greater versatility with adjustable arm length and drill head positioning, making them ideal for larger, complex workpieces. Pillar drills provide precision and stability for smaller, repetitive drilling tasks, making them suitable for workshop environments with limited space.

Conclusion: Radial Drill vs Pillar Drill

Radial drills offer greater flexibility and reach with their adjustable arm, making them ideal for larger workpieces and complex drilling tasks. Pillar drills provide superior stability and precision for smaller, repetitive drilling jobs due to their fixed vertical column. Your choice between a radial drill and a pillar drill depends on the scale and complexity of your projects, prioritizing either versatility or precision.

Radial drill vs pillar drill Infographic

libmatt.com

libmatt.com