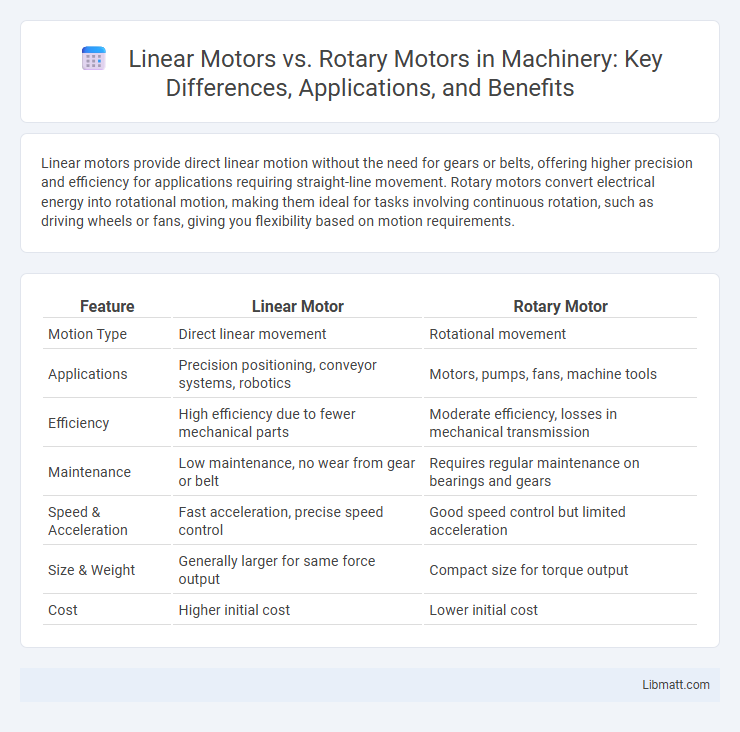

Linear motors provide direct linear motion without the need for gears or belts, offering higher precision and efficiency for applications requiring straight-line movement. Rotary motors convert electrical energy into rotational motion, making them ideal for tasks involving continuous rotation, such as driving wheels or fans, giving you flexibility based on motion requirements.

Table of Comparison

| Feature | Linear Motor | Rotary Motor |

|---|---|---|

| Motion Type | Direct linear movement | Rotational movement |

| Applications | Precision positioning, conveyor systems, robotics | Motors, pumps, fans, machine tools |

| Efficiency | High efficiency due to fewer mechanical parts | Moderate efficiency, losses in mechanical transmission |

| Maintenance | Low maintenance, no wear from gear or belt | Requires regular maintenance on bearings and gears |

| Speed & Acceleration | Fast acceleration, precise speed control | Good speed control but limited acceleration |

| Size & Weight | Generally larger for same force output | Compact size for torque output |

| Cost | Higher initial cost | Lower initial cost |

Introduction to Linear and Rotary Motors

Linear motors convert electrical energy directly into linear motion without the need for mechanical transmission, offering precise positioning and high acceleration in applications like automation and transportation. Rotary motors generate rotational motion through electromagnetic interactions, widely used in industrial machinery, robotics, and electric vehicles for torque and continuous rotation. Understanding the fundamental differences between linear and rotary motors is essential for selecting the appropriate actuator type based on motion requirements and system design.

Basic Operating Principles

Linear motors convert electrical energy directly into linear motion through electromagnetic force without the need for rotary-to-linear motion conversion mechanisms, using a stator and a moving coil or magnet. Rotary motors generate rotational motion by electromagnetic interaction between a stationary stator and a rotating rotor, which is then often converted to linear motion via gears or screws if needed. The absence of mechanical transmission components in linear motors results in higher precision, faster acceleration, and reduced wear compared to rotary motors configured for linear displacement.

Key Differences Between Linear and Rotary Motors

Linear motors produce direct straight-line motion by generating electromagnetic force along a linear path, whereas rotary motors create rotational motion through torque around an axis. Unlike rotary motors that convert electrical energy into rotational force suitable for applications like fans and wheels, linear motors eliminate the need for mechanical transmission components, offering higher precision and faster response times in positioning systems. Understanding these key differences helps you select the appropriate motor type for efficient motion control in automation and robotics.

Common Applications of Linear Motors

Linear motors are widely used in applications requiring precise, high-speed, and smooth linear motion such as semiconductor manufacturing, CNC machinery, and automation assembly lines. Their ability to produce direct linear force without mechanical transmission makes them ideal for pick-and-place robots and conveyor systems. In the medical field, linear motors enable accurate positioning in MRI machines and surgical equipment.

Common Applications of Rotary Motors

Rotary motors are widely used in industrial automation, robotics, and conveyor systems due to their efficient torque and speed control. They power applications such as machine tools, pumps, fans, and electric vehicles, where precise rotational motion is essential. Your choice of a rotary motor can enhance performance in sectors demanding continuous and reliable rotational movement.

Performance Comparison: Speed, Force, and Efficiency

Linear motors deliver high-speed motion with direct linear force, eliminating mechanical transmission losses found in rotary motors. Rotary motors provide rotational movement that can be converted to linear motion but often suffer from reduced efficiency due to gear or belt mechanisms. Your choice depends on the application's demand for precise linear speed, maximum force output, and overall energy efficiency.

Advantages of Linear Motors

Linear motors offer direct-drive motion, eliminating the need for gears or belts, which results in higher precision and faster response times. Their compact design reduces mechanical complexity and maintenance requirements, enhancing reliability in applications requiring smooth, accurate linear positioning. You benefit from increased efficiency and quieter operation compared to traditional rotary motors converted to linear motion.

Advantages of Rotary Motors

Rotary motors offer high torque density, making them ideal for applications requiring rotational motion with precise speed control and efficiency. Their compact design supports a wide range of industrial uses, from robotics to conveyor systems, providing reliable performance and easier integration compared to linear motors. Your choice of a rotary motor can result in cost-effective operation and durable mechanics suited for continuous or cyclic rotational tasks.

Factors to Consider When Choosing Motor Type

Key factors to consider when choosing between a linear motor and a rotary motor include the required motion type, precision, and application space constraints. Linear motors excel in direct straight-line motion with high speed and accuracy, ideal for applications like semiconductor manufacturing, while rotary motors are preferred for applications demanding rotational movement and torque, such as robotics. Your decision should account for factors like load capacity, maintenance requirements, and integration complexity to optimize performance and efficiency.

Future Trends in Motor Technology

Linear motors and rotary motors are evolving rapidly with trends toward increased efficiency, precision, and integration of smart technologies such as IoT and AI-driven predictive maintenance. Advances in materials science, like high-temperature superconductors and improved magnetic materials, are enhancing motor performance and reducing energy consumption. Your applications will benefit from these innovations through more compact designs, higher torque density, and seamless automation in manufacturing and robotics.

Linear motor vs rotary motor Infographic

libmatt.com

libmatt.com