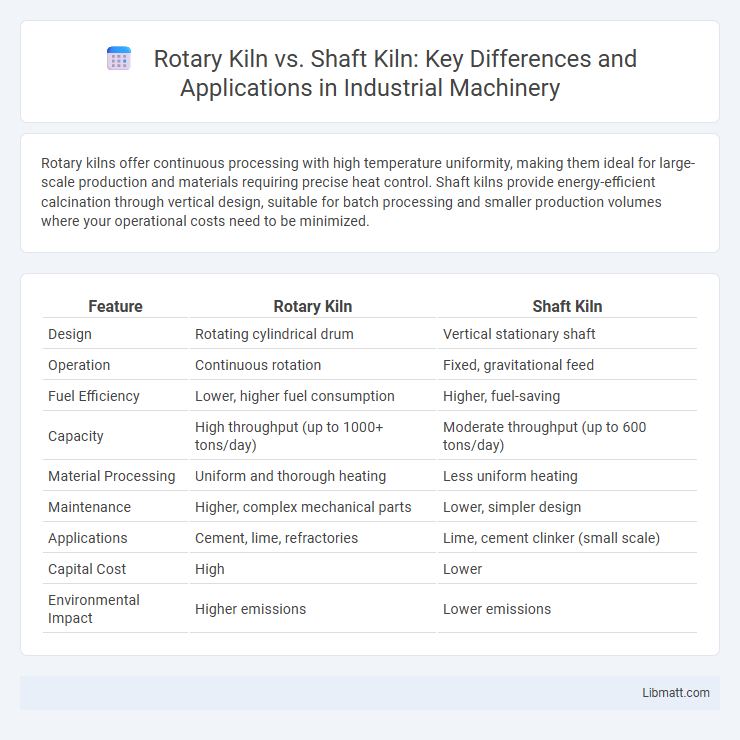

Rotary kilns offer continuous processing with high temperature uniformity, making them ideal for large-scale production and materials requiring precise heat control. Shaft kilns provide energy-efficient calcination through vertical design, suitable for batch processing and smaller production volumes where your operational costs need to be minimized.

Table of Comparison

| Feature | Rotary Kiln | Shaft Kiln |

|---|---|---|

| Design | Rotating cylindrical drum | Vertical stationary shaft |

| Operation | Continuous rotation | Fixed, gravitational feed |

| Fuel Efficiency | Lower, higher fuel consumption | Higher, fuel-saving |

| Capacity | High throughput (up to 1000+ tons/day) | Moderate throughput (up to 600 tons/day) |

| Material Processing | Uniform and thorough heating | Less uniform heating |

| Maintenance | Higher, complex mechanical parts | Lower, simpler design |

| Applications | Cement, lime, refractories | Lime, cement clinker (small scale) |

| Capital Cost | High | Lower |

| Environmental Impact | Higher emissions | Lower emissions |

Introduction to Rotary Kiln and Shaft Kiln

Rotary kilns are cylindrical, rotating furnaces widely used for continuous high-temperature processing of materials like cement, lime, and refractories, offering uniform heat distribution and precise temperature control. Shaft kilns are vertical, stationary structures where raw materials descend by gravity through heat zones, primarily utilized for lime calcination with lower energy efficiency compared to rotary kilns. The choice between rotary and shaft kilns depends on factors such as production capacity, fuel consumption, and material properties.

Working Principles of Rotary Kiln

The working principle of a rotary kiln involves a rotating cylindrical shell that processes raw materials at high temperatures by gradually moving them through the kiln's inclined length. Heat is transferred through conduction, convection, and radiation, enabling chemical reactions such as calcination or sintering to occur efficiently. Unlike shaft kilns, rotary kilns provide continuous processing with better temperature control, making them ideal for handling a wide range of materials and ensuring consistent product quality for your industrial needs.

Operating Mechanism of Shaft Kiln

The operating mechanism of a shaft kiln involves vertical cylindrical chambers where raw materials descend by gravity while hot gases rise countercurrently, enabling heat exchange and calcination. Shaft kilns maintain a continuous feed at the top and discharge clinker or calcined product at the bottom, ensuring efficient thermal processing with minimal fuel consumption. The indirect heating and slower material movement contrast with rotary kilns' rotation-driven mixing and heat transfer.

Key Differences Between Rotary Kiln and Shaft Kiln

Rotary kilns feature a rotating cylindrical shell that provides continuous mixing and uniform heat distribution, making them ideal for large-scale thermal processing of materials like cement and lime. Shaft kilns operate by passing raw material vertically through a fixed, vertical structure where heat moves counter-currently, suitable mainly for smaller batches and energy-efficient calcination. Your choice depends on production capacity, material feed size, and thermal efficiency, as rotary kilns offer flexibility and higher throughput while shaft kilns excel in fuel economy and simpler design.

Advantages of Rotary Kiln Technology

Rotary kiln technology offers enhanced temperature control, ensuring uniform heat distribution and consistent product quality in cement production. Its continuous operation capability increases efficiency and reduces downtime compared to shaft kilns. You benefit from greater flexibility in fuel use and raw material handling, resulting in optimized operational costs and improved environmental performance.

Benefits of Shaft Kiln Technology

Shaft kiln technology offers significant energy efficiency and reduced operational costs compared to rotary kilns, as it uses the counter-current heat exchange to maximize fuel utilization. Shaft kilns require less maintenance and have a simpler design, resulting in lower downtime and prolonged equipment lifespan. By choosing shaft kiln technology, you benefit from a more sustainable, cost-effective solution ideal for producing high-quality lime and cement clinker.

Energy Efficiency: Rotary Kiln vs Shaft Kiln

Rotary kilns typically exhibit lower energy efficiency compared to shaft kilns due to longer heat transfer paths and higher fuel consumption during operation. Shaft kilns leverage counter-current heat exchange, allowing better heat recovery from exhaust gases and reducing overall energy usage by up to 30%. Industrial case studies indicate that energy savings in shaft kilns range between 15-25% when processing similar raw materials under comparable conditions.

Environmental Impact Comparison

Rotary kilns generally produce higher CO2 emissions due to continuous fuel consumption and larger operational scale compared to shaft kilns, which operate with lower fuel input and better heat recovery, resulting in reduced greenhouse gas emissions. Shaft kilns demonstrate improved energy efficiency and lower particulate emissions, contributing to a smaller environmental footprint, especially in small to medium-scale production. Your choice between these kiln types can significantly influence environmental compliance and sustainability goals in industrial processes.

Industrial Applications and Suitability

Rotary kilns are highly versatile and widely used in cement manufacturing, lime production, and waste incineration due to their continuous processing capabilities and ability to handle large-scale operations. Shaft kilns are more suitable for small to medium-scale production, particularly in lime and refractory material industries, where batch processing and lower fuel consumption are advantageous. Your choice depends on the required production capacity, fuel efficiency, and specific material handling needs in industrial applications.

Choosing the Right Kiln for Your Process

Rotary kilns offer continuous processing with uniform heating, making them ideal for large-scale production requiring precise temperature control and consistent material quality. Shaft kilns excel in energy efficiency and batch processing, suitable for smaller volumes and materials that benefit from counter-current heat exchange. Understanding your process scale, temperature requirements, and energy considerations helps you choose the right kiln for optimal performance and cost-effectiveness.

Rotary kiln vs shaft kiln Infographic

libmatt.com

libmatt.com