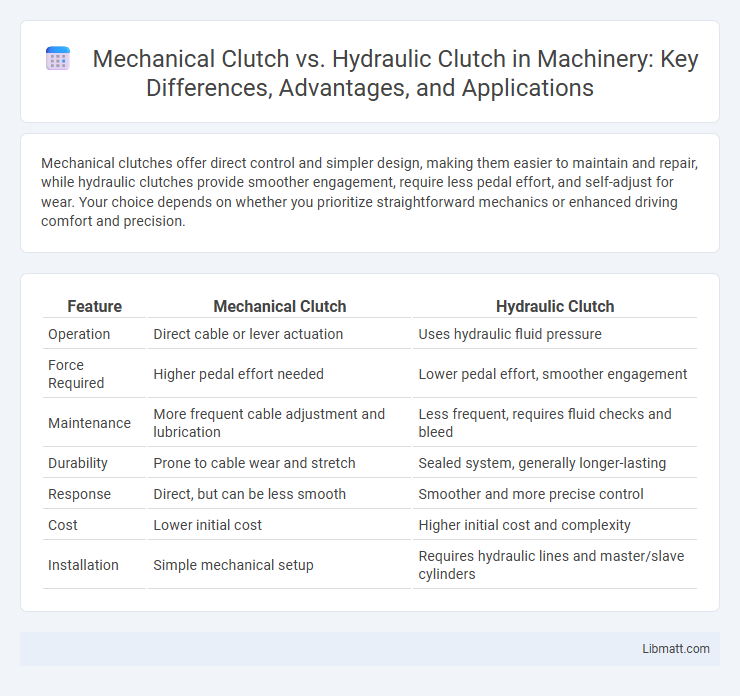

Mechanical clutches offer direct control and simpler design, making them easier to maintain and repair, while hydraulic clutches provide smoother engagement, require less pedal effort, and self-adjust for wear. Your choice depends on whether you prioritize straightforward mechanics or enhanced driving comfort and precision.

Table of Comparison

| Feature | Mechanical Clutch | Hydraulic Clutch |

|---|---|---|

| Operation | Direct cable or lever actuation | Uses hydraulic fluid pressure |

| Force Required | Higher pedal effort needed | Lower pedal effort, smoother engagement |

| Maintenance | More frequent cable adjustment and lubrication | Less frequent, requires fluid checks and bleed |

| Durability | Prone to cable wear and stretch | Sealed system, generally longer-lasting |

| Response | Direct, but can be less smooth | Smoother and more precise control |

| Cost | Lower initial cost | Higher initial cost and complexity |

| Installation | Simple mechanical setup | Requires hydraulic lines and master/slave cylinders |

Introduction to Clutch Systems

Mechanical clutch systems use a direct cable or linkage to engage and disengage the clutch, providing a straightforward and reliable connection. Hydraulic clutches operate through fluid pressure, offering smoother and more consistent clutch engagement with reduced pedal effort. Your choice between these systems depends on factors like maintenance, responsiveness, and vehicle performance preferences.

Overview of Mechanical Clutch

Mechanical clutches operate via a direct cable or rod linkage controlled by the driver, providing a straightforward and reliable engagement mechanism between the engine and transmission. They typically require manual adjustment to maintain optimal performance and can offer a more tactile and responsive feel during gear shifts. Your choice of a mechanical clutch ensures ease of maintenance and cost-effectiveness, especially in older or simpler vehicle designs.

Overview of Hydraulic Clutch

A hydraulic clutch uses fluid pressure to engage and disengage the clutch, providing smoother and more precise control compared to a mechanical clutch, which relies on a direct cable or lever system. The hydraulic system includes components such as a master cylinder, slave cylinder, and hydraulic fluid, enabling self-adjusting mechanisms that reduce maintenance needs. This design enhances driver comfort, reduces pedal effort, and improves overall vehicle performance in demanding driving conditions.

Key Components Comparison

Mechanical clutches rely on a cable or rod to transfer force from the pedal to the clutch mechanism, featuring key components such as the clutch pedal, cable, release lever, and pressure plate. Hydraulic clutches utilize fluid pressure to engage and disengage, comprising a master cylinder, hydraulic fluid, slave cylinder, and pressure plate for smoother, self-adjusting operation. Your choice between mechanical and hydraulic systems impacts maintenance frequency, pedal effort, and overall reliability due to these fundamental component differences.

Working Principles: Mechanical vs Hydraulic

Mechanical clutches operate using a direct cable or linkage system that physically engages and disengages the clutch by transmitting force from the pedal to the clutch mechanism. Hydraulic clutches utilize fluid pressure generated in a master cylinder to actuate a slave cylinder, providing smoother and more consistent clutch engagement. Understanding the working principles of your mechanical or hydraulic clutch system helps ensure optimal performance and maintenance.

Performance Differences

Mechanical clutches offer direct and immediate engagement, providing precise control and a strong mechanical feel, making them ideal for performance driving that demands quick response. Hydraulic clutches use fluid pressure to engage and disengage, delivering smoother operation and reducing pedal effort, which enhances comfort during extended driving or daily use. Your choice depends on whether you prioritize sharp performance feedback or ease of use and consistent clutch modulation.

Maintenance and Durability

Mechanical clutches typically require more frequent maintenance due to cable adjustments and wear on the linkage, whereas hydraulic clutches offer self-adjusting mechanisms that reduce regular maintenance needs. Hydraulic systems generally provide better durability because they maintain consistent pressure and reduce cable stretch, leading to longer component life. However, hydraulic clutches can be more costly to repair if leaks or seal failures occur compared to the simpler mechanical clutch components.

Cost and Installation Factors

Mechanical clutches generally cost less and have simpler installation procedures due to their straightforward cable or rod actuation system, making them a budget-friendly choice for many vehicles. Hydraulic clutches, while typically more expensive, offer smoother and more precise control but require additional components such as master and slave cylinders, increasing installation complexity and labor costs. Choosing between the two depends on budget constraints and the desired ease of installation, as well as vehicle compatibility.

Suitability for Different Applications

Mechanical clutches are best suited for applications where simplicity, cost-effectiveness, and ease of maintenance are priorities, such as in older vehicles, motorcycles, and certain industrial machinery. Hydraulic clutches offer smoother and more consistent operation, making them ideal for high-performance cars, modern vehicles, and heavy-duty equipment requiring precise control and less driver effort. Your choice depends on the specific requirements of the application, including desired durability, ease of use, and performance.

Conclusion: Choosing the Right Clutch System

A mechanical clutch offers simplicity, lower cost, and easier maintenance, making it ideal for vehicles with straightforward performance needs. Hydraulic clutches deliver smoother operation and reduced pedal effort, enhancing driving comfort and precision, especially in high-performance or heavy-duty applications. Selecting the right clutch system depends on balancing budget constraints with desired driving experience and vehicle specifications.

Mechanical clutch vs hydraulic clutch Infographic

libmatt.com

libmatt.com