Split-phase motors use a starting winding with high resistance to create a phase shift for initial torque, making them suitable for low starting torque applications. Capacitor start motors incorporate a capacitor in series with the auxiliary winding, providing higher starting torque ideal for heavy-load situations, ensuring your motor starts more efficiently under demanding conditions.

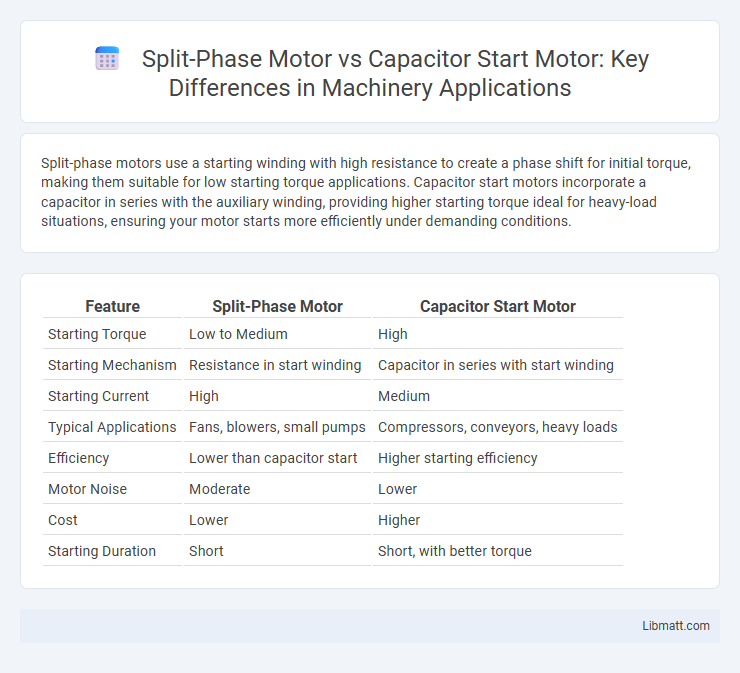

Table of Comparison

| Feature | Split-Phase Motor | Capacitor Start Motor |

|---|---|---|

| Starting Torque | Low to Medium | High |

| Starting Mechanism | Resistance in start winding | Capacitor in series with start winding |

| Starting Current | High | Medium |

| Typical Applications | Fans, blowers, small pumps | Compressors, conveyors, heavy loads |

| Efficiency | Lower than capacitor start | Higher starting efficiency |

| Motor Noise | Moderate | Lower |

| Cost | Lower | Higher |

| Starting Duration | Short | Short, with better torque |

Introduction to Split-Phase and Capacitor Start Motors

Split-phase motors use a centrifugal switch to disconnect the start winding, relying on the phase difference created by the start and run windings for initial torque. Capacitor start motors incorporate a capacitor in series with the start winding, generating a higher phase shift that produces greater starting torque compared to split-phase designs. Your choice between these motors depends on the starting torque requirements and application demands.

Basic Working Principle of Split-Phase Motors

Split-phase motors operate on the principle of creating a phase difference between two winding coils--a start winding and a run winding--using the inherent resistance and inductance in each coil to generate a rotating magnetic field. This phase difference produces the initial torque that starts the motor without the need for auxiliary components like capacitors. Your choice between split-phase and capacitor start motors depends on the starting torque requirements and application efficiency.

Basic Working Principle of Capacitor Start Motors

Capacitor start motors use an auxiliary winding connected in series with a capacitor to create a phase shift, generating a strong starting torque. This design enables your motor to overcome initial inertia more effectively compared to split-phase motors, which rely on resistance and inductance differences without capacitors. The capacitor's presence enhances starting performance by improving current phase angle and motor efficiency during startup.

Construction Differences

Split-phase motors feature a main winding and an auxiliary winding with a centrifugal switch to disconnect the start winding once the motor reaches a certain speed, while capacitor start motors incorporate a capacitor in series with the start winding to improve starting torque. The split-phase motor's auxiliary winding is designed to create a phase difference through resistance, whereas the capacitor start motor achieves a larger phase shift due to the capacitor, resulting in enhanced starting performance. Capacitor start motors typically have a more complex construction due to the presence of the capacitor and its associated circuitry compared to the simpler design of split-phase motors.

Starting Mechanism Comparison

Split-phase motors use a start winding with higher resistance to create a phase shift for starting torque, relying on the inherent inductance difference between windings. Capacitor start motors employ a capacitor in series with the start winding, producing a stronger phase shift and higher starting torque compared to split-phase motors. Your choice depends on startup load requirements, with capacitor start motors better suited for heavier loads due to their enhanced starting mechanism.

Performance and Efficiency

Split-phase motors offer moderate starting torque and efficiency but tend to draw higher inrush current, making them less suitable for heavy-load applications. Capacitor start motors provide superior starting torque and improved efficiency due to the phase-shifting effect of the capacitor, resulting in smoother operation and reduced energy consumption. Choosing a capacitor start motor can enhance your equipment's performance and energy efficiency, especially in demanding startup conditions.

Typical Applications

Split-phase motors are commonly used in low-power applications such as small pumps, fans, and household appliances due to their simple design and cost-effectiveness. Capacitor start motors are preferred in higher starting torque applications like air compressors, refrigeration compressors, and machinery requiring rapid acceleration. The enhanced starting performance of capacitor start motors makes them suitable for equipment with heavier loads and frequent starts.

Cost and Maintenance Considerations

Split-phase motors typically cost less upfront than capacitor start motors due to their simpler design and fewer components, making them a budget-friendly choice for basic applications. Maintenance for split-phase motors is generally minimal, but they may experience reduced lifespan and efficiency under frequent start-stop cycles. Your decision should weigh the lower initial cost against the potential for increased energy consumption and maintenance frequency in capacitor start motors, which feature higher starting torque and longer durability but come with higher initial expenses and more complex upkeep.

Advantages and Disadvantages of Each Type

Split-phase motors offer advantages such as simple construction and low cost, making them suitable for applications with moderate starting torque requirements. However, their disadvantages include lower starting torque and relatively higher starting current, which can limit performance in heavy-load conditions. Capacitor start motors provide higher starting torque and improved efficiency due to the phase-shifting capacitor but are generally more expensive and complex, with the potential for capacitor failure reducing reliability.

Choosing the Right Motor for Your Application

Split-phase motors offer reliable starting torque with a simpler design, making them suitable for applications like fans, blowers, and small machinery where moderate starting torque is sufficient. Capacitor start motors deliver higher starting torque due to the capacitor's phase-shifting effect, ideal for heavier loads such as compressors, conveyors, and pumps requiring robust starting power. Selecting the right motor depends on load characteristics, starting torque demands, and overall application requirements to maximize efficiency and performance.

Split-phase motor vs capacitor start motor Infographic

libmatt.com

libmatt.com