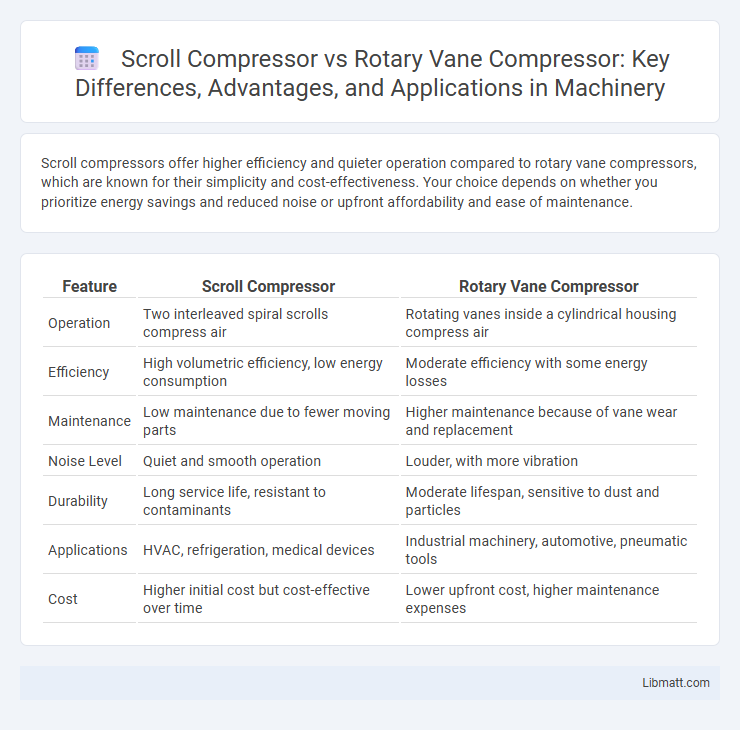

Scroll compressors offer higher efficiency and quieter operation compared to rotary vane compressors, which are known for their simplicity and cost-effectiveness. Your choice depends on whether you prioritize energy savings and reduced noise or upfront affordability and ease of maintenance.

Table of Comparison

| Feature | Scroll Compressor | Rotary Vane Compressor |

|---|---|---|

| Operation | Two interleaved spiral scrolls compress air | Rotating vanes inside a cylindrical housing compress air |

| Efficiency | High volumetric efficiency, low energy consumption | Moderate efficiency with some energy losses |

| Maintenance | Low maintenance due to fewer moving parts | Higher maintenance because of vane wear and replacement |

| Noise Level | Quiet and smooth operation | Louder, with more vibration |

| Durability | Long service life, resistant to contaminants | Moderate lifespan, sensitive to dust and particles |

| Applications | HVAC, refrigeration, medical devices | Industrial machinery, automotive, pneumatic tools |

| Cost | Higher initial cost but cost-effective over time | Lower upfront cost, higher maintenance expenses |

Introduction to Scroll and Rotary Vane Compressors

Scroll compressors feature two interleaved spiral components, with one fixed and the other orbiting, efficiently compressing air or gas with minimal vibration and noise. Rotary vane compressors use a rotor with multiple sliding vanes inside a cylindrical housing, creating variable volume chambers to compress air effectively. Each type is valued for specific industrial applications, offering distinct advantages in energy efficiency, compactness, and maintenance requirements.

How Scroll Compressors Work

Scroll compressors operate by using two interleaved spiral scrolls, one stationary and one orbiting, to compress refrigerant gas steadily and efficiently. This mechanism minimizes pulsation and noise, leading to smoother operation and higher energy efficiency compared to rotary vane compressors, which rely on a rotating vane to trap and compress air. The continuous compression in scroll compressors enhances durability and performance in HVAC systems and refrigeration applications.

How Rotary Vane Compressors Operate

Rotary vane compressors operate by utilizing a rotor mounted eccentrically inside a cylindrical housing, where multiple vanes slide radially to trap and compress air or gas within decreasing chamber volumes. The continuous rotation of the rotor moves the trapped air from the intake side to the discharge side, achieving efficient compression and smooth airflow. This sliding vane mechanism provides reliable operation with low pulsation and generally lower maintenance compared to scroll compressors.

Efficiency Comparison: Scroll vs Rotary Vane Compressors

Scroll compressors typically offer higher efficiency than rotary vane compressors due to their fewer moving parts and reduced internal leakage, resulting in less energy loss during operation. Rotary vane compressors, while effective for certain low-pressure applications, often exhibit greater friction and wear, leading to increased energy consumption over time. The enhanced volumetric efficiency and quieter operation of scroll compressors make them a preferred choice for energy-conscious HVAC and refrigeration systems.

Performance and Output Differences

Scroll compressors deliver higher efficiency and quieter operation by using interleaved spiral elements that compress refrigerant smoothly without pulsation. Rotary vane compressors generate variable output with a rotating vane mechanism, typically offering greater airflow but lower efficiency and more noise compared to scroll designs. Scroll compressors excel in sustained high-pressure applications, while rotary vane units provide flexibility in output for fluctuating demand scenarios.

Noise Levels: Which Compressor is Quieter?

Scroll compressors generally produce lower noise levels compared to rotary vane compressors due to their continuous, smooth compression mechanism that minimizes vibration and mechanical friction. Rotary vane compressors create more noise because of the sliding vanes interacting with the compressor housing, generating higher mechanical friction and turbulence. For applications requiring quieter operation, such as medical or laboratory environments, scroll compressors are typically preferred for their superior noise performance.

Maintenance Requirements and Costs

Scroll compressors generally require less maintenance than rotary vane compressors due to fewer moving parts, resulting in lower long-term service costs. Rotary vane compressors often need regular lubrication and vane replacement, which can increase maintenance frequency and expenses. Choosing a scroll compressor can help minimize downtime and reduce your overall maintenance budget.

Lifespan and Durability

Scroll compressors typically offer longer lifespan and higher durability due to fewer moving parts and reduced mechanical stress, making them ideal for continuous operation. Rotary vane compressors, while robust, experience more wear from the sliding vanes and frequent maintenance intervals, which can shorten their overall lifespan. Industrial applications favor scroll compressors for sustained reliability and lower long-term maintenance costs.

Best Applications for Scroll and Rotary Vane Compressors

Scroll compressors excel in HVAC systems, refrigeration, and medical equipment due to their high efficiency, low noise, and reliable performance under continuous operation. Rotary vane compressors are ideal for automotive air conditioning, pneumatic tools, and small industrial applications where variable capacity and compact design offer flexibility and quick startup. Selecting between the two depends on application-specific needs such as pressure range, operating environment, and maintenance requirements.

Which Compressor Type is Right for Your Needs?

Scroll compressors excel in applications requiring high efficiency and low noise levels, making them ideal for HVAC systems and refrigeration. Rotary vane compressors provide consistent pressure and are better suited for industrial uses needing steady airflow and durability under continuous operation. Selecting the right compressor depends on factors such as energy efficiency, noise tolerance, maintenance frequency, and specific application requirements.

Scroll compressor vs rotary vane compressor Infographic

libmatt.com

libmatt.com