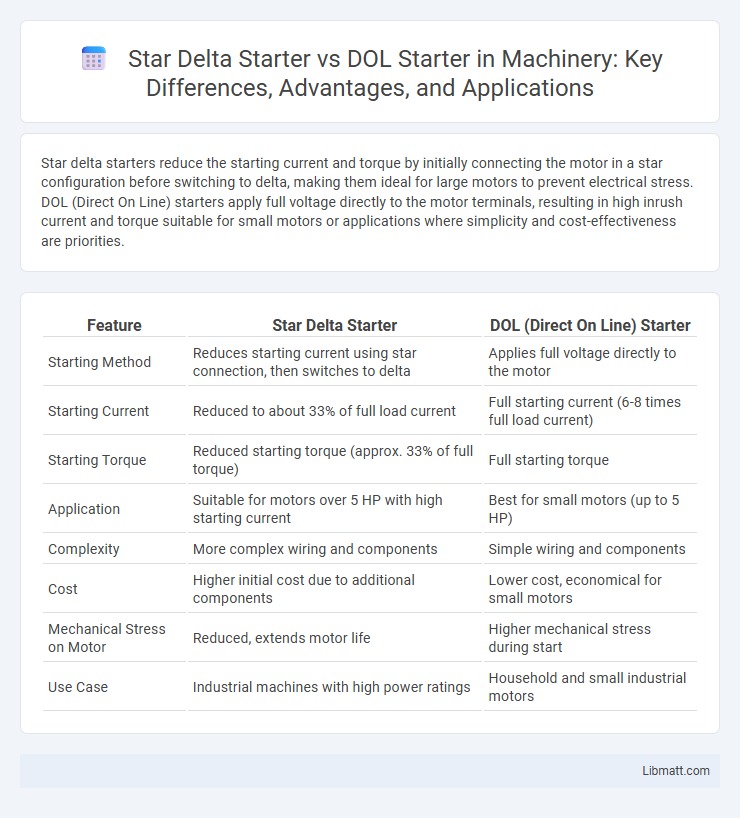

Star delta starters reduce the starting current and torque by initially connecting the motor in a star configuration before switching to delta, making them ideal for large motors to prevent electrical stress. DOL (Direct On Line) starters apply full voltage directly to the motor terminals, resulting in high inrush current and torque suitable for small motors or applications where simplicity and cost-effectiveness are priorities.

Table of Comparison

| Feature | Star Delta Starter | DOL (Direct On Line) Starter |

|---|---|---|

| Starting Method | Reduces starting current using star connection, then switches to delta | Applies full voltage directly to the motor |

| Starting Current | Reduced to about 33% of full load current | Full starting current (6-8 times full load current) |

| Starting Torque | Reduced starting torque (approx. 33% of full torque) | Full starting torque |

| Application | Suitable for motors over 5 HP with high starting current | Best for small motors (up to 5 HP) |

| Complexity | More complex wiring and components | Simple wiring and components |

| Cost | Higher initial cost due to additional components | Lower cost, economical for small motors |

| Mechanical Stress on Motor | Reduced, extends motor life | Higher mechanical stress during start |

| Use Case | Industrial machines with high power ratings | Household and small industrial motors |

Introduction to Motor Starters

Star delta starters reduce the starting current of three-phase induction motors by initially connecting the motor windings in a star configuration and then switching to a delta connection once the motor reaches a certain speed. DOL (Direct-On-Line) starters apply full voltage directly to the motor terminals, resulting in high starting current and torque, which is suitable for small motors with low starting current requirements. Your choice between star delta and DOL starters depends on motor size, starting current limitations, and application requirements.

Overview of DOL (Direct-On-Line) Starter

The Direct-On-Line (DOL) starter instantly applies full voltage to a motor, resulting in a high starting current, typically 6 to 8 times the motor's rated current. This simple and cost-effective method suits small motors where high starting torque is required without complex control. Your choice depends on motor size and application, as DOL starters are ideal for low-power motors but may cause mechanical stress in larger machines.

Overview of Star Delta Starter

A Star Delta starter is an electrical motor starter that reduces starting current by initially connecting the motor windings in a star (Y) configuration, then switching to a delta configuration for normal operation. This method lowers the starting current to approximately one-third of the direct online (DOL) starter, reducing electrical stress on the power supply and extending motor life. Star delta starters are commonly used for high-power motors in industrial applications where minimizing inrush current is critical.

Key Differences Between Star Delta and DOL Starters

Star delta starters reduce the initial current starting torque by connecting the motor windings in a star configuration during startup, shifting to delta for normal operation, while DOL (Direct On Line) starters apply full line voltage immediately, resulting in higher starting current and torque. Star delta starters are preferred for large motors to minimize electrical and mechanical stress, whereas DOL starters suit smaller motors due to their simplicity and cost-effectiveness. The primary difference lies in current reduction and motor stress management, impacting the choice based on motor size and application requirements.

Working Principle of DOL Starter

The Direct On Line (DOL) starter operates by directly connecting the motor terminals to the power supply, allowing full voltage to be applied immediately for maximum starting torque. This method causes a high inrush current, typically 6 to 8 times the motor's rated current, which can stress electrical components and mechanical parts. The simple design and cost-effectiveness of the DOL starter make it suitable for small motors with low starting current requirements.

Working Principle of Star Delta Starter

The working principle of a Star Delta starter involves initially connecting the motor windings in a star configuration to reduce the voltage and current during startup, which limits the starting current and torque. After a preset time delay, the starter switches the motor windings to a delta configuration, allowing full line voltage for normal operation and efficient performance. Your motor benefits from reduced electrical stress during startup, minimizing mechanical wear and extending its lifespan.

Advantages of DOL Starter

DOL (Direct On Line) starters provide a simple and cost-effective solution with straightforward installation and minimal wiring requirements, making them ideal for small motors and applications where high starting torque is needed. They offer quick starting without any complex control systems, ensuring reliable performance and easy troubleshooting. Your equipment benefits from immediate full voltage application, which helps in achieving a strong initial torque for heavy load starting conditions.

Advantages of Star Delta Starter

Star delta starters reduce the starting current and minimize voltage drops, making them ideal for heavy-duty motors and industrial applications where power stability is crucial. They enhance motor lifespan by limiting mechanical stress during startup compared to direct-on-line (DOL) starters. You benefit from improved energy efficiency and lower electrical costs due to the reduced inrush current of star delta starters.

Applications and Suitability

Star delta starters are ideal for reducing starting current in large induction motors used in heavy industrial applications like compressors, conveyors, and pumps. DOL starters provide direct full-voltage starting, making them suitable for small motors with lower starting current requirements, commonly found in domestic or light commercial settings. Your choice depends on the motor size and load conditions, as star delta starters enhance efficiency in high-power applications, while DOL starters ensure simplicity and cost-effectiveness for smaller motors.

Conclusion: Choosing the Right Starter

Selecting between a Star Delta Starter and a Direct On Line (DOL) Starter depends on motor size, starting current, and application requirements. Star Delta Starters are preferred for large motors to reduce starting current and limit mechanical stress, offering energy efficiency during startup. For smaller motors or simple applications, DOL Starters provide direct full voltage, ensuring straightforward installation and cost-effectiveness.

Star delta starter vs DOL starter Infographic

libmatt.com

libmatt.com