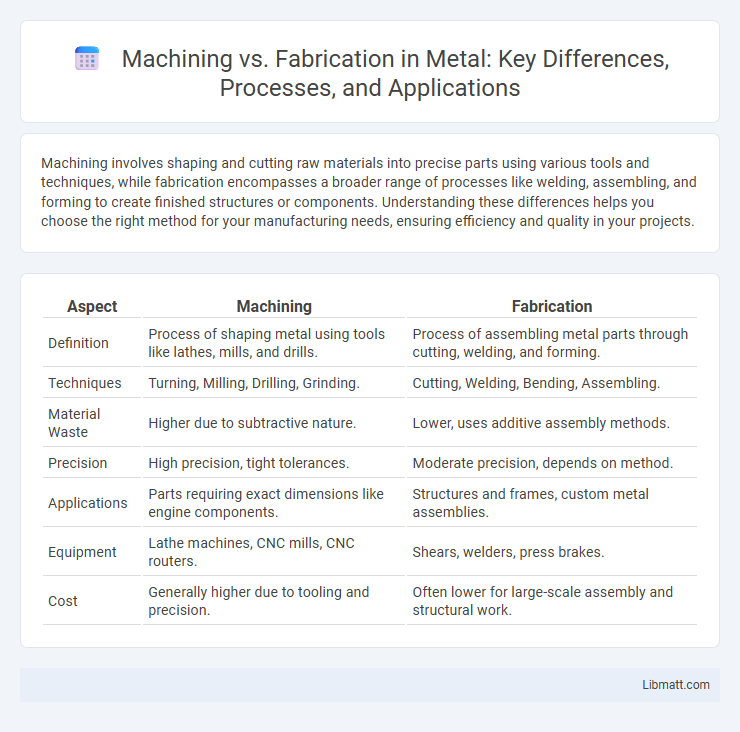

Machining involves shaping and cutting raw materials into precise parts using various tools and techniques, while fabrication encompasses a broader range of processes like welding, assembling, and forming to create finished structures or components. Understanding these differences helps you choose the right method for your manufacturing needs, ensuring efficiency and quality in your projects.

Table of Comparison

| Aspect | Machining | Fabrication |

|---|---|---|

| Definition | Process of shaping metal using tools like lathes, mills, and drills. | Process of assembling metal parts through cutting, welding, and forming. |

| Techniques | Turning, Milling, Drilling, Grinding. | Cutting, Welding, Bending, Assembling. |

| Material Waste | Higher due to subtractive nature. | Lower, uses additive assembly methods. |

| Precision | High precision, tight tolerances. | Moderate precision, depends on method. |

| Applications | Parts requiring exact dimensions like engine components. | Structures and frames, custom metal assemblies. |

| Equipment | Lathe machines, CNC mills, CNC routers. | Shears, welders, press brakes. |

| Cost | Generally higher due to tooling and precision. | Often lower for large-scale assembly and structural work. |

Introduction to Machining and Fabrication

Machining involves the precise removal of material from a workpiece using tools such as lathes, mills, and drills to achieve the desired shape and dimensions. Fabrication encompasses a broader range of processes, including cutting, bending, and assembling metal components to create finished structures or products. Both machining and fabrication are essential in manufacturing industries, with machining focusing on shaping parts and fabrication emphasizing the construction of complex assemblies.

Defining Machining: Processes and Techniques

Machining involves precise material removal using tools such as lathes, mills, and drills to shape metal or plastic components. Techniques include turning, milling, drilling, grinding, and electrical discharge machining (EDM), enabling high accuracy and complex geometries. These processes focus on subtractive manufacturing, enhancing part precision and surface finish in industries like aerospace, automotive, and medical device production.

Understanding Fabrication: Methods and Materials

Fabrication involves transforming raw materials into finished products through processes like cutting, welding, bending, and assembling. Common materials used in fabrication include metals such as steel, aluminum, and stainless steel, as well as plastics and composites, chosen based on strength, durability, and application requirements. Understanding these methods and materials helps you select the most efficient fabrication process to meet your production goals and quality standards.

Key Differences Between Machining and Fabrication

Machining involves the precise removal of material using tools such as lathes, mills, or drills to achieve exact dimensions and smooth finishes on metal or plastic parts. Fabrication encompasses a broader range of processes, including cutting, bending, and assembling raw materials into structures or products, often requiring welding, fastening, or forming techniques. Understanding these key differences helps you choose the right manufacturing method for your project's specific requirements, whether it prioritizes precision or structural assembly.

Common Applications in Various Industries

Machining is widely used in aerospace for producing precision components like turbine blades and engine parts, while fabrication is essential in construction for assembling steel frameworks and structural supports. In automotive manufacturing, machining shapes engine blocks and transmission parts, whereas fabrication creates welded chassis and body panels. Both processes play crucial roles in electronics by machining intricate circuit components and fabricating enclosures.

Advantages of Machining

Machining offers superior precision and tight tolerances, making it ideal for components requiring high accuracy and repeatability. It enables complex geometries and intricate detailing that are difficult to achieve with traditional fabrication methods. Your projects benefit from reduced material waste and faster production cycles, enhancing overall efficiency and cost-effectiveness.

Benefits of Fabrication

Fabrication offers significant benefits such as the ability to create complex, custom metal structures quickly and efficiently, reducing lead times and overall production costs. It allows for high precision in assembling components through welding, cutting, and bending, ensuring structural integrity and durability. Fabrication also supports scalable manufacturing processes, making it ideal for both small batch and large-scale industrial applications.

Factors to Consider When Choosing Between Machining and Fabrication

When choosing between machining and fabrication, factors such as material type, precision requirements, production volume, and design complexity play crucial roles. Machining offers high precision and is ideal for intricate parts, while fabrication excels in assembling large structures with welded or joined components. Your decision should also consider cost efficiency and lead time based on project specifications and the desired finish quality.

Cost Implications and Efficiency Comparison

Machining typically involves higher initial costs due to specialized equipment and skilled labor but offers precise and repeatable results, making it efficient for complex or small-volume projects. Fabrication generally has lower upfront expenses and is more cost-effective for large-scale production with simpler designs, as it focuses on assembling parts through cutting, bending, and welding. Understanding your project's scope and volume helps optimize both cost implications and efficiency when choosing between machining and fabrication.

Future Trends in Machining and Fabrication Technologies

Future trends in machining and fabrication technologies emphasize increased automation through AI-driven CNC machines and robotic systems, enhancing precision and efficiency. Additive manufacturing integration with traditional subtractive processes is transforming prototyping and production timelines. Your manufacturing operations benefit from real-time data analytics and IoT connectivity, enabling smarter decision-making and predictive maintenance.

Machining vs Fabrication Infographic

libmatt.com

libmatt.com