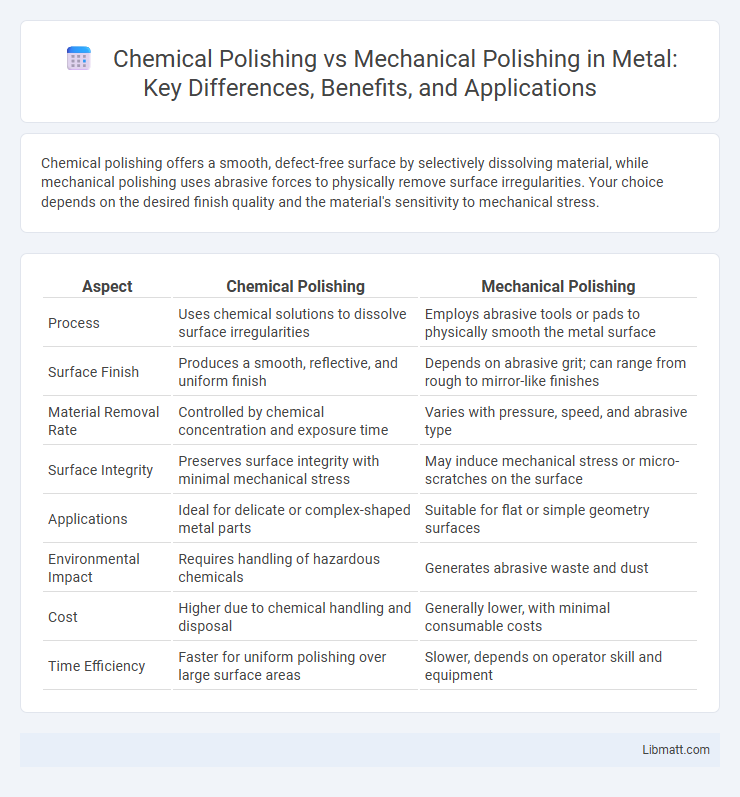

Chemical polishing offers a smooth, defect-free surface by selectively dissolving material, while mechanical polishing uses abrasive forces to physically remove surface irregularities. Your choice depends on the desired finish quality and the material's sensitivity to mechanical stress.

Table of Comparison

| Aspect | Chemical Polishing | Mechanical Polishing |

|---|---|---|

| Process | Uses chemical solutions to dissolve surface irregularities | Employs abrasive tools or pads to physically smooth the metal surface |

| Surface Finish | Produces a smooth, reflective, and uniform finish | Depends on abrasive grit; can range from rough to mirror-like finishes |

| Material Removal Rate | Controlled by chemical concentration and exposure time | Varies with pressure, speed, and abrasive type |

| Surface Integrity | Preserves surface integrity with minimal mechanical stress | May induce mechanical stress or micro-scratches on the surface |

| Applications | Ideal for delicate or complex-shaped metal parts | Suitable for flat or simple geometry surfaces |

| Environmental Impact | Requires handling of hazardous chemicals | Generates abrasive waste and dust |

| Cost | Higher due to chemical handling and disposal | Generally lower, with minimal consumable costs |

| Time Efficiency | Faster for uniform polishing over large surface areas | Slower, depends on operator skill and equipment |

Overview of Chemical and Mechanical Polishing

Chemical polishing uses controlled chemical reactions to selectively dissolve surface irregularities, enhancing surface smoothness and removing oxides without mechanical abrasion. Mechanical polishing involves abrasive materials or tools physically grinding or buffing the surface to achieve a smoother finish, often requiring multiple grit sizes for progressive refinement. Your choice between chemical and mechanical polishing depends on the desired surface quality, material compatibility, and precision requirements of the application.

How Chemical Polishing Works

Chemical polishing works by applying a controlled chemical solution to the metal surface, which selectively dissolves microscopic peaks and smooths irregularities at the atomic level. This process removes a thin layer of material uniformly across the surface, enhancing reflectivity and reducing surface roughness without mechanical abrasion. Your metal parts achieve a clean, polished finish with minimal mechanical stress or distortion, ideal for precision applications.

How Mechanical Polishing Works

Mechanical polishing works by physically abrading the surface with abrasive materials such as sandpaper, polishing wheels, or diamond paste to remove roughness and imperfections. The process involves repetitive rubbing or buffing motions that gradually smoothen the substrate, enhancing its reflectivity and surface finish. Unlike chemical polishing, mechanical polishing relies solely on mechanical forces and controlled pressure to achieve the desired surface texture without involving chemical reactions.

Key Differences Between Chemical and Mechanical Polishing

Chemical polishing relies on controlled chemical reactions to dissolve surface irregularities, resulting in a smoother finish without mechanical force, while mechanical polishing uses abrasive materials and physical contact to remove surface imperfections. The chemical method offers uniform smoothing ideal for complex geometries, whereas mechanical polishing provides more control over surface texture and is effective for harder materials. Chemical polishing often yields a cleaner, more reflective surface with less risk of introducing micro-scratches compared to the mechanical approach.

Surface Quality: Chemical vs. Mechanical Methods

Chemical polishing delivers a smoother, more uniform surface finish by selectively removing material at the microscopic level, reducing surface roughness and minimizing defects. Mechanical polishing relies on abrasive techniques that can introduce scratches and inconsistencies, potentially compromising surface quality. Your choice between chemical and mechanical polishing should consider the desired level of surface precision and the specific application requirements.

Applications in Industry: Chemical vs. Mechanical Polishing

Chemical polishing is widely used in the semiconductor and aerospace industries to enhance surface smoothness by selectively removing microscopic layers, resulting in reduced surface stress and improved corrosion resistance. Mechanical polishing, favored in automotive and metal fabrication sectors, employs abrasive materials to physically remove surface irregularities, providing precise control over dimensional tolerances and surface finish quality. Both methods are essential for achieving specific surface characteristics required in electronic component manufacturing and heavy machinery production, with chemical polishing excelling in achieving ultra-smooth finishes and mechanical polishing offering robust material removal.

Advantages of Chemical Polishing

Chemical polishing offers superior surface smoothness by selectively removing microscopic peaks and valleys without causing mechanical stress or deformation. This process enhances corrosion resistance and improves brightness and reflectivity, making it ideal for delicate or complex-shaped metal components. Your parts benefit from increased dimensional accuracy and reduced contamination risk compared to mechanical polishing methods.

Advantages of Mechanical Polishing

Mechanical polishing offers precise surface control and uniform material removal, enhancing the finish quality on metals and alloys. It improves surface flatness and reduces stress concentration, which benefits components subject to fatigue and wear. This method is also versatile, capable of handling complex geometries and large surfaces efficiently compared to chemical polishing.

Limitations and Drawbacks: Chemical vs. Mechanical Approaches

Chemical polishing may cause uneven material removal and limited control over surface finish, posing challenges for complex geometries or delicate components. Mechanical polishing often results in surface scratches, subsurface deformation, and requires significant manual labor or specialized equipment. Your choice between chemical and mechanical polishing should consider these drawbacks relative to the specific material and precision requirements of your application.

Choosing the Right Polishing Method for Your Needs

Selecting the ideal polishing method depends on the material type, desired surface finish, and application requirements. Chemical polishing offers superior uniformity and smoothness for metals like stainless steel and aluminum, while mechanical polishing provides more control for shaping and removing thicker layers on harder materials. Evaluating factors such as cost, environmental impact, and precision guides the choice between chemical and mechanical polishing techniques.

Chemical polishing vs mechanical polishing Infographic

libmatt.com

libmatt.com