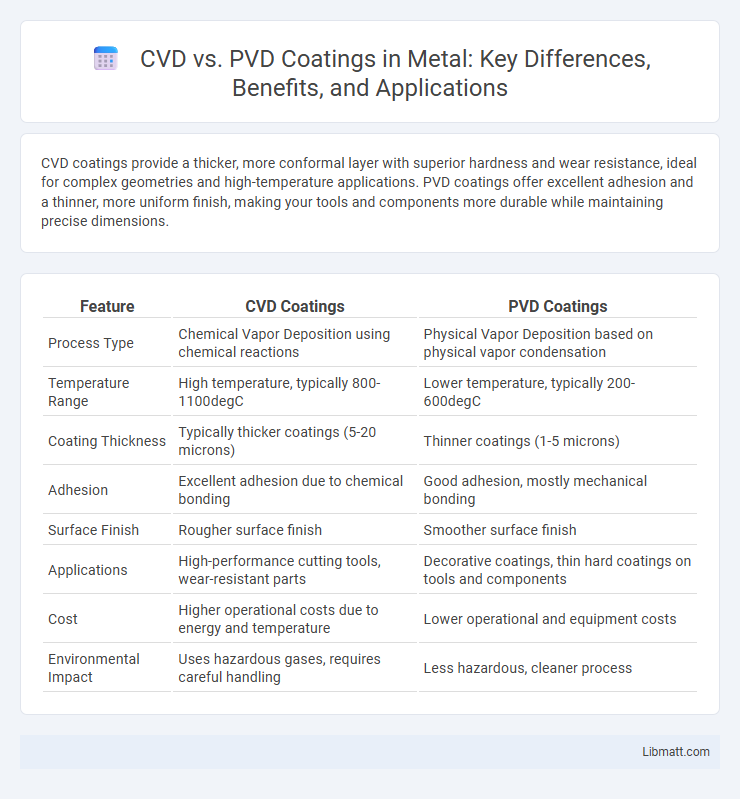

CVD coatings provide a thicker, more conformal layer with superior hardness and wear resistance, ideal for complex geometries and high-temperature applications. PVD coatings offer excellent adhesion and a thinner, more uniform finish, making your tools and components more durable while maintaining precise dimensions.

Table of Comparison

| Feature | CVD Coatings | PVD Coatings |

|---|---|---|

| Process Type | Chemical Vapor Deposition using chemical reactions | Physical Vapor Deposition based on physical vapor condensation |

| Temperature Range | High temperature, typically 800-1100degC | Lower temperature, typically 200-600degC |

| Coating Thickness | Typically thicker coatings (5-20 microns) | Thinner coatings (1-5 microns) |

| Adhesion | Excellent adhesion due to chemical bonding | Good adhesion, mostly mechanical bonding |

| Surface Finish | Rougher surface finish | Smoother surface finish |

| Applications | High-performance cutting tools, wear-resistant parts | Decorative coatings, thin hard coatings on tools and components |

| Cost | Higher operational costs due to energy and temperature | Lower operational and equipment costs |

| Environmental Impact | Uses hazardous gases, requires careful handling | Less hazardous, cleaner process |

Introduction to CVD and PVD Coatings

Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) are advanced coating techniques used to enhance surface properties such as hardness, wear resistance, and corrosion protection. CVD involves chemical reactions at elevated temperatures to form thin films, while PVD relies on physical processes like sputtering or evaporation to deposit material layers. Your choice between CVD and PVD coatings depends on application requirements, including coating thickness, adhesion, and operating environment.

Overview of Coating Technologies

Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) are advanced coating technologies used to enhance surface properties such as hardness, wear resistance, and corrosion protection. CVD involves chemical reactions of gaseous precursors at high temperatures to form a solid coating, producing thick, uniform layers with excellent adhesion, commonly used in cutting tools and aerospace components. PVD deposits thin films through physical processes like evaporation or sputtering, offering precise control over coating thickness and composition, widely applied in decorative finishes and semiconductor manufacturing.

Chemical Vapor Deposition (CVD): Process and Features

Chemical Vapor Deposition (CVD) is a high-temperature process where gaseous precursors react or decompose on a substrate surface, forming a thin, uniform coating with excellent adhesion and hardness. CVD coatings offer superior thermal stability and chemical resistance, making them ideal for tools and components exposed to extreme environments. Your choice of CVD ensures enhanced wear resistance and extended service life compared to other coating methods like Physical Vapor Deposition (PVD).

Physical Vapor Deposition (PVD): Process and Features

Physical Vapor Deposition (PVD) is a vacuum coating process where material is vaporized from a solid source and deposited as a thin film onto the substrate, offering high precision and strong adhesion. PVD coatings provide excellent hardness, wear resistance, and corrosion protection, making them ideal for cutting tools, aerospace components, and medical devices. Your choice of PVD can enhance surface durability while maintaining tight dimensional tolerances, unlike Chemical Vapor Deposition (CVD) which operates at higher temperatures and produces thicker coatings.

Key Differences Between CVD and PVD Coatings

CVD (Chemical Vapor Deposition) coatings utilize chemical reactions at high temperatures to deposit thin films, resulting in dense and strong coatings with excellent adhesion. PVD (Physical Vapor Deposition) coatings involve physical processes like evaporation or sputtering to create thin films, offering precise control over coating thickness and composition at lower temperatures. Key differences include CVD's ability to coat complex geometries uniformly and its typically higher processing temperature compared to PVD's more versatile application on temperature-sensitive substrates and faster deposition rates.

Material Compatibility in CVD vs PVD

CVD coatings exhibit excellent material compatibility with complex-shaped substrates and refractory materials due to their high-temperature deposition process, making them ideal for ceramics and carbides. PVD coatings are more suitable for temperature-sensitive materials like aluminum and stainless steel because of their low-temperature, line-of-sight deposition technique. The choice between CVD and PVD depends heavily on substrate thermal tolerance and desired coating adherence to optimize performance and durability.

Performance and Durability Comparison

CVD coatings offer superior hardness and wear resistance, making them ideal for high-temperature and aggressive environments, while PVD coatings provide excellent adhesion and are better suited for applications requiring thinner, more precise layers. PVD coatings generally exhibit higher corrosion resistance and versatility on complex geometries but may wear faster under extreme mechanical stress compared to CVD coatings. Understanding your specific application needs will help determine whether the enhanced durability of CVD or the adaptability of PVD coatings delivers optimal performance and longevity.

Applications of CVD and PVD Coatings

CVD coatings are extensively used in high-temperature environments such as aerospace engine components, cutting tools, and semiconductor devices due to their excellent thermal stability and strong adhesion. PVD coatings find broad applications in decorative finishes, automotive parts, optical films, and wear-resistant surfaces, offering precise control over coating thickness and composition. Both technologies enhance surface properties like hardness, corrosion resistance, and friction reduction across diverse industrial and manufacturing sectors.

Environmental and Cost Considerations

Chemical Vapor Deposition (CVD) coatings typically require higher temperatures and use hazardous gases, leading to greater energy consumption and more stringent environmental controls compared to Physical Vapor Deposition (PVD). PVD processes operate at lower temperatures, produce less chemical waste, and have a smaller environmental footprint, making them more cost-effective in terms of energy and waste management. While CVD coatings may offer superior adhesion and durability, PVD coatings often result in lower overall production costs due to reduced energy needs and simpler environmental compliance.

Choosing the Right Coating Method for Your Needs

CVD coatings offer superior adhesion and high-temperature resistance, making them ideal for applications requiring durability in extreme environments. PVD coatings provide excellent surface finish and precise thickness control, perfect for decorative or wear-resistant purposes where aesthetics matter. Evaluate your specific performance requirements, operating conditions, and budget to choose the right coating method for your needs.

CVD vs PVD coatings Infographic

libmatt.com

libmatt.com