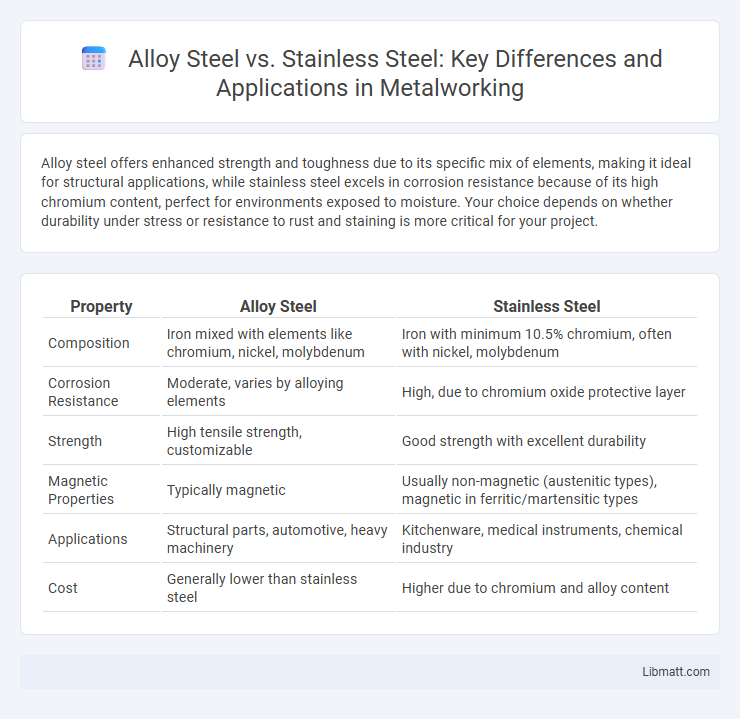

Alloy steel offers enhanced strength and toughness due to its specific mix of elements, making it ideal for structural applications, while stainless steel excels in corrosion resistance because of its high chromium content, perfect for environments exposed to moisture. Your choice depends on whether durability under stress or resistance to rust and staining is more critical for your project.

Table of Comparison

| Property | Alloy Steel | Stainless Steel |

|---|---|---|

| Composition | Iron mixed with elements like chromium, nickel, molybdenum | Iron with minimum 10.5% chromium, often with nickel, molybdenum |

| Corrosion Resistance | Moderate, varies by alloying elements | High, due to chromium oxide protective layer |

| Strength | High tensile strength, customizable | Good strength with excellent durability |

| Magnetic Properties | Typically magnetic | Usually non-magnetic (austenitic types), magnetic in ferritic/martensitic types |

| Applications | Structural parts, automotive, heavy machinery | Kitchenware, medical instruments, chemical industry |

| Cost | Generally lower than stainless steel | Higher due to chromium and alloy content |

Introduction to Alloy Steel and Stainless Steel

Alloy steel contains a mixture of iron with elements such as chromium, nickel, manganese, and vanadium to enhance its mechanical properties, making it ideal for strength and durability in industrial applications. Stainless steel, a subset of alloy steel, specifically contains at least 10.5% chromium which provides exceptional corrosion resistance and a shiny surface finish. The main distinction lies in stainless steel's ability to resist oxidation and staining, which makes it the preferred choice for environments exposed to moisture and chemicals.

Chemical Composition Differences

Alloy steel contains a combination of carbon with various elements such as manganese, chromium, nickel, and molybdenum to enhance mechanical properties and strength. Stainless steel is specifically characterized by a minimum of 10.5% chromium content, which forms a passive layer of chromium oxide for corrosion resistance. The key difference lies in stainless steel's higher chromium content and presence of other elements like nickel, which improve oxidation resistance compared to alloy steel's focus on strength and hardness.

Mechanical Properties Comparison

Alloy steel offers higher tensile strength and improved hardness due to its varied alloying elements like manganese, nickel, and chromium, making it suitable for heavy-duty applications. Stainless steel provides excellent corrosion resistance and maintains good mechanical properties at elevated temperatures, ideal for environments exposed to moisture or chemicals. Your choice depends on whether mechanical strength or corrosion resistance is the priority in the specific application.

Corrosion Resistance Capabilities

Alloy steel offers moderate corrosion resistance depending on its alloying elements like chromium and nickel, but it generally requires protective coatings for enhanced durability. Stainless steel contains a minimum of 10.5% chromium, forming a passive oxide layer that provides superior corrosion resistance even in harsh environments. Choosing stainless steel for your applications ensures long-lasting protection against rust and oxidation without additional treatments.

Common Applications of Alloy Steel

Alloy steel is widely used in automotive components, construction equipment, and heavy machinery due to its enhanced strength and durability. It is common in manufacturing gears, shafts, and pipelines where resistance to wear and high stress is essential. The steel's ability to withstand high temperatures also makes it ideal for power plant and pressure vessel applications.

Popular Uses of Stainless Steel

Stainless steel is widely used in industries requiring corrosion resistance and durability, such as kitchen appliances, medical instruments, and architectural structures. Its application extends to food processing equipment, chemical containers, and automotive components due to its hygienic properties and strength. The metal's ability to withstand extreme temperatures and harsh environments makes it ideal for aerospace and marine industries as well.

Cost Analysis: Alloy Steel vs Stainless Steel

Alloy steel generally offers lower upfront costs compared to stainless steel, making it a cost-effective option for applications requiring enhanced strength and hardness. Stainless steel, despite its higher initial price, provides superior corrosion resistance and longevity, reducing maintenance and replacement expenses over time. The total cost of ownership for stainless steel often outweighs alloy steel in environments prone to corrosion, justifying its premium price for long-term durability.

Machinability and Fabrication Methods

Alloy steel offers excellent machinability due to its balanced carbon content and alloying elements, making it ideal for precision machining and welding processes such as cutting, grinding, and drilling. Stainless steel, while corrosion-resistant, typically requires specialized fabrication methods like laser cutting or plasma cutting to maintain its surface finish and prevent heat-related damage. Your choice between the two depends on the specific fabrication complexity and the machinability required for your project.

Longevity and Maintenance Requirements

Alloy steel exhibits exceptional longevity due to its enhanced strength and resistance to wear, making it suitable for heavy-duty applications with moderate maintenance. Stainless steel offers superior corrosion resistance, significantly reducing maintenance needs and extending its lifespan in harsh or moist environments. Your choice depends on whether durability under mechanical stress or minimal upkeep in corrosive conditions is the priority.

Choosing the Right Steel for Your Project

Alloy steel offers enhanced strength and toughness through added elements like chromium, nickel, and molybdenum, making it ideal for heavy-duty structural applications and machinery components. Stainless steel contains a minimum of 10.5% chromium, providing excellent corrosion resistance, which suits it for environments requiring durability against rust and chemical exposure. Selecting the right steel depends on project requirements such as mechanical strength, corrosion resistance, and budget constraints.

alloy steel vs stainless steel Infographic

libmatt.com

libmatt.com