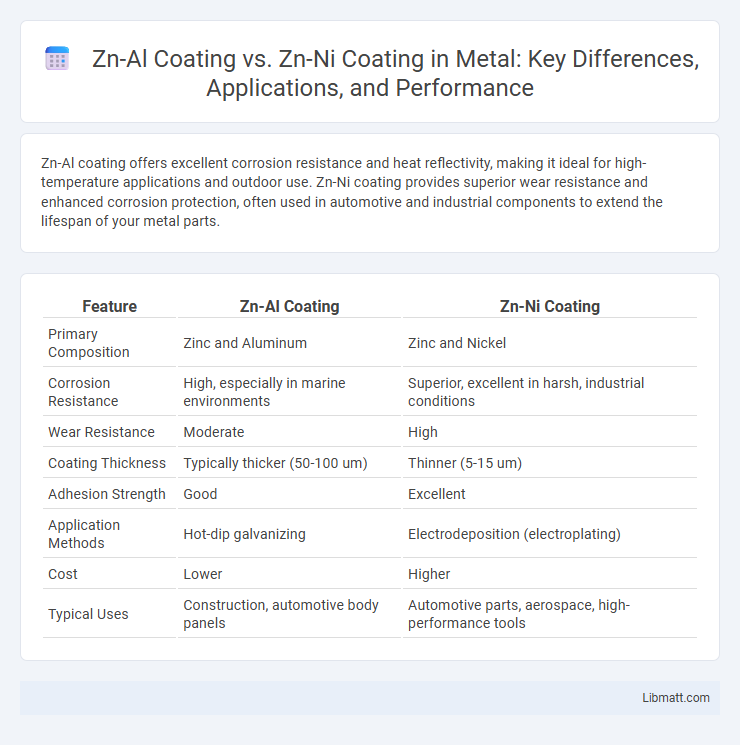

Zn-Al coating offers excellent corrosion resistance and heat reflectivity, making it ideal for high-temperature applications and outdoor use. Zn-Ni coating provides superior wear resistance and enhanced corrosion protection, often used in automotive and industrial components to extend the lifespan of your metal parts.

Table of Comparison

| Feature | Zn-Al Coating | Zn-Ni Coating |

|---|---|---|

| Primary Composition | Zinc and Aluminum | Zinc and Nickel |

| Corrosion Resistance | High, especially in marine environments | Superior, excellent in harsh, industrial conditions |

| Wear Resistance | Moderate | High |

| Coating Thickness | Typically thicker (50-100 um) | Thinner (5-15 um) |

| Adhesion Strength | Good | Excellent |

| Application Methods | Hot-dip galvanizing | Electrodeposition (electroplating) |

| Cost | Lower | Higher |

| Typical Uses | Construction, automotive body panels | Automotive parts, aerospace, high-performance tools |

Introduction to Metal Coatings

Zn-Al coatings provide excellent corrosion resistance and high heat reflectivity, making them ideal for automotive and construction applications. Zn-Ni coatings offer superior wear resistance and enhanced protection against salt spray corrosion, commonly used in aerospace and defense industries. Both coatings serve critical roles in extending metal durability but differ in chemical composition and performance characteristics.

Overview of Zn-Al Coating

Zn-Al coating provides superior corrosion resistance and high-temperature oxidation protection compared to traditional zinc coatings, making it ideal for automotive and construction applications. The aluminum content in Zn-Al alloys forms a dense, stable oxide layer that enhances durability and extends the lifespan of steel components. If you need reliable protection under extreme conditions, Zn-Al coating offers a robust solution with excellent mechanical properties.

Overview of Zn-Ni Coating

Zn-Ni coating offers superior corrosion resistance and improved mechanical properties compared to traditional Zn-Al coating, making it ideal for automotive and aerospace applications. This alloy coating provides enhanced cathodic protection and better adhesion on steel substrates, resulting in longer service life in harsh environments. Zn-Ni coatings typically contain 10-15% nickel, which contributes to their excellent wear resistance and higher hardness levels compared to Zn-Al coatings.

Composition and Microstructure Differences

Zn-Al coating primarily consists of a zinc matrix with aluminum dispersed, enhancing corrosion resistance through the formation of a dense, adherent oxide layer. Zn-Ni coating features a zinc-nickel alloy with a microstructure comprising fine intermetallic compounds, providing superior corrosion protection and improved hardness. Your choice depends on the specific application requirements, as Zn-Al offers better high-temperature stability while Zn-Ni excels in aggressive environment durability.

Corrosion Resistance Comparison

Zn-Ni coatings offer superior corrosion resistance compared to Zn-Al coatings due to the formation of stable and dense passive layers that enhance protection in harsh environments. Zn-Al coatings provide moderate corrosion resistance suitable for general applications but may degrade faster under aggressive conditions like salt spray or acidic exposure. Your choice between Zn-Al and Zn-Ni coatings should consider the specific environmental stressors to ensure optimal longevity and performance.

Mechanical Properties and Durability

Zn-Al coatings exhibit superior mechanical properties with enhanced corrosion resistance and wear durability compared to traditional Zn-Ni coatings. Zn-Al's higher hardness and better elongation improve impact resistance, while Zn-Ni offers excellent corrosion protection but lower mechanical resilience. Your choice depends on the application's demand for strength versus corrosion resistance, with Zn-Al better suited for abrasive environments and Zn-Ni for high-corrosion settings.

Application Industries and Use Cases

Zn-Al coatings are widely used in construction, automotive, and appliances industries due to their excellent corrosion resistance and high-temperature performance, making them ideal for structural components and outdoor equipment. Zn-Ni coatings are favored in aerospace, automotive, and electronics sectors for their superior wear resistance, enhanced corrosion protection, and excellent adhesion properties, particularly in critical parts like fasteners and connectors. These coatings are selected based on industry-specific requirements such as durability, environmental exposure, and mechanical stress tolerance.

Coating Process and Application Methods

Zn-Al coating typically involves a hot-dip galvanizing process where steel is immersed in a bath containing molten zinc and aluminum, forming a metallurgical bond with excellent corrosion resistance and heat stability. Zn-Ni coating is commonly applied using an electroplating method, allowing precise control over coating thickness and composition, making it ideal for automotive and aerospace components requiring enhanced wear and corrosion protection. Both coatings offer distinct application methods suited to different industrial needs, with Zn-Al preferred for structural steel and Zn-Ni for high-performance engineering parts.

Cost and Economic Considerations

Zn-Al coatings typically offer lower upfront costs and are widely used for general corrosion protection due to their cost-effectiveness in large-scale applications. Zn-Ni coatings, while more expensive initially, provide superior corrosion resistance and longer service life, which can reduce maintenance and replacement costs over time. Evaluating the total cost of ownership shows Zn-Ni coatings may deliver better economic value in harsh environments despite higher material and processing expenses.

Environmental Impact and Sustainability

Zn-Al coatings generally offer superior environmental benefits due to their lower toxicity and reduced need for hazardous waste treatment compared to Zn-Ni coatings, which often involve more complex chemical processes and heavier metal usage. The recycling potential and longer lifespan of Zn-Al coatings contribute significantly to sustainability by minimizing resource consumption and waste generation. When selecting a coating, your choice impacts ecological footprint and regulatory compliance in industries prioritizing green manufacturing.

Zn-Al coating vs Zn-Ni coating Infographic

libmatt.com

libmatt.com