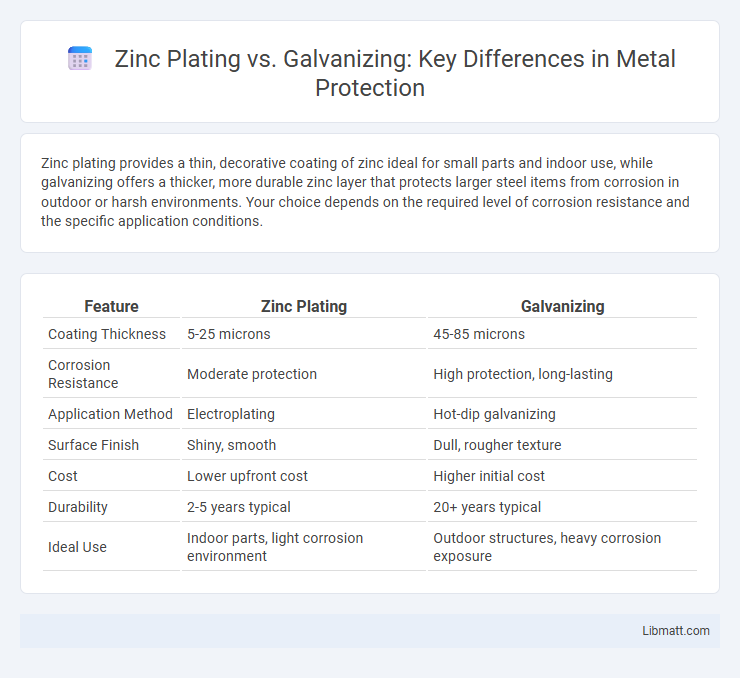

Zinc plating provides a thin, decorative coating of zinc ideal for small parts and indoor use, while galvanizing offers a thicker, more durable zinc layer that protects larger steel items from corrosion in outdoor or harsh environments. Your choice depends on the required level of corrosion resistance and the specific application conditions.

Table of Comparison

| Feature | Zinc Plating | Galvanizing |

|---|---|---|

| Coating Thickness | 5-25 microns | 45-85 microns |

| Corrosion Resistance | Moderate protection | High protection, long-lasting |

| Application Method | Electroplating | Hot-dip galvanizing |

| Surface Finish | Shiny, smooth | Dull, rougher texture |

| Cost | Lower upfront cost | Higher initial cost |

| Durability | 2-5 years typical | 20+ years typical |

| Ideal Use | Indoor parts, light corrosion environment | Outdoor structures, heavy corrosion exposure |

Introduction to Zinc Plating and Galvanizing

Zinc plating involves applying a thin layer of zinc to enhance corrosion resistance on metal surfaces, primarily through an electrochemical process. Galvanizing, typically hot-dip galvanizing, immerses steel or iron in molten zinc, creating a thicker, more durable protective coating. Your choice between zinc plating and galvanizing depends on factors like environmental exposure, desired longevity, and cost efficiency.

How Zinc Plating Works

Zinc plating works by electrochemically depositing a thin layer of zinc onto the surface of a metal, typically steel, to provide corrosion resistance and enhance durability. The process involves submerging the metal object in a zinc salt solution and applying an electric current, causing zinc ions to adhere and form a protective coating. Your metal components benefit from zinc plating's decorative finish and precise thickness control, which differs from the thicker, hot-dip coating achieved in galvanizing.

How Galvanizing Works

Galvanizing protects steel by coating it with a layer of zinc through a hot-dip process where the metal is immersed in molten zinc, creating a strong metallurgical bond. This zinc layer acts as a sacrificial anode, corroding first to shield the underlying steel from rust and environmental damage. The resulting coating provides long-lasting corrosion resistance, especially suitable for outdoor and industrial applications.

Key Differences Between Zinc Plating and Galvanizing

Zinc plating involves applying a thin zinc coating through electrochemical deposition, offering precise control and a smooth finish ideal for smaller components, while galvanizing uses a hot-dip process to create a thicker, more durable zinc layer suitable for outdoor or heavy-duty applications. The corrosion resistance of galvanizing generally surpasses zinc plating due to its robust coating thickness, protecting steel for decades in harsh environments. Zinc plating is more cost-effective for high-volume, lightweight parts but requires additional protective coatings for prolonged exposure, unlike the inherently long-lasting galvanized layers.

Comparative Corrosion Resistance

Zinc plating offers a thin protective layer that provides moderate corrosion resistance, ideal for indoor or low-exposure environments. Galvanizing applies a thicker zinc coating, resulting in superior corrosion resistance suitable for harsh outdoor or industrial conditions. Your choice depends on the environmental exposure and longevity requirements of the metal component.

Durability and Longevity

Zinc plating offers a thin, protective layer ideal for indoor applications where corrosion resistance is moderate, typically lasting several months to a few years without significant wear. Galvanizing provides a much thicker coating through a hot-dip process, ensuring superior durability and longevity, often protecting steel structures for decades even in harsh outdoor environments. When considering your project's lifespan and exposure conditions, galvanizing generally outperforms zinc plating in long-term corrosion resistance and maintenance needs.

Applications and Typical Uses

Zinc plating is commonly used for small automotive parts, hardware, and fasteners due to its thin, decorative, and corrosion-resistant coating ideal for indoor and mild environments. Galvanizing applies a thicker zinc layer, providing robust protection primarily for structural steel components in construction, bridges, and outdoor infrastructure exposed to harsh weather conditions. Both methods enhance metal durability, but galvanizing is preferred for heavy-duty, long-term corrosion resistance in industrial and marine applications.

Cost Analysis: Zinc Plating vs Galvanizing

Zinc plating generally incurs lower initial costs compared to galvanizing due to its thinner coating and shorter process time. Galvanizing, while more expensive upfront, provides greater long-term corrosion resistance and durability, potentially reducing maintenance and replacement expenses. Cost analysis must consider lifecycle expenses, with galvanizing offering better value for applications exposed to harsh environments.

Environmental and Safety Considerations

Zinc plating typically involves the use of hazardous chemicals and generates toxic waste that requires careful disposal to minimize environmental impact, whereas galvanizing, especially hot-dip galvanizing, produces fewer harmful byproducts and offers more robust corrosion resistance, reducing long-term environmental risks. Your choice between zinc plating and galvanizing should consider workplace safety protocols, as zinc plating involves electrochemical processes with potential exposure to acids and heavy metals, while galvanizing involves high-temperature baths that require protective measures against fumes and burns. Regulatory compliance and waste management practices are critical for both methods to ensure environmental sustainability and worker safety.

Choosing the Right Protection Method

Zinc plating provides a thin, decorative layer ideal for protecting small to medium-sized steel parts from corrosion, offering a smooth, bright finish that enhances aesthetic appeal. Galvanizing involves coating steel with a thicker layer of zinc through hot-dip immersion, delivering superior corrosion resistance and durability, especially for outdoor or heavy-duty applications exposed to harsh environments. Assess your project's environmental conditions, budget, and required longevity to choose the protection method that best preserves your metal components.

zinc plating vs galvanizing Infographic

libmatt.com

libmatt.com