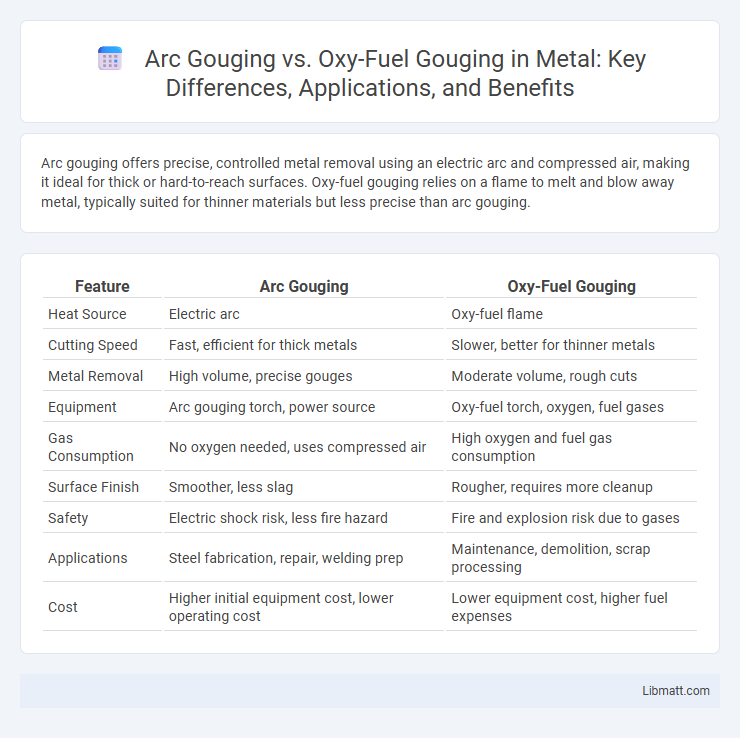

Arc gouging offers precise, controlled metal removal using an electric arc and compressed air, making it ideal for thick or hard-to-reach surfaces. Oxy-fuel gouging relies on a flame to melt and blow away metal, typically suited for thinner materials but less precise than arc gouging.

Table of Comparison

| Feature | Arc Gouging | Oxy-Fuel Gouging |

|---|---|---|

| Heat Source | Electric arc | Oxy-fuel flame |

| Cutting Speed | Fast, efficient for thick metals | Slower, better for thinner metals |

| Metal Removal | High volume, precise gouges | Moderate volume, rough cuts |

| Equipment | Arc gouging torch, power source | Oxy-fuel torch, oxygen, fuel gases |

| Gas Consumption | No oxygen needed, uses compressed air | High oxygen and fuel gas consumption |

| Surface Finish | Smoother, less slag | Rougher, requires more cleanup |

| Safety | Electric shock risk, less fire hazard | Fire and explosion risk due to gases |

| Applications | Steel fabrication, repair, welding prep | Maintenance, demolition, scrap processing |

| Cost | Higher initial equipment cost, lower operating cost | Lower equipment cost, higher fuel expenses |

Introduction to Arc Gouging and Oxy-Fuel Gouging

Arc gouging utilizes a high-temperature electric arc to melt and remove metal efficiently, making it ideal for precise and rapid metal cutting or removal tasks. Oxy-fuel gouging relies on a combustion process using oxygen and fuel gas to oxidize and blow away metal, suitable for thicker materials and applications where slower, controlled metal removal is needed. Understanding these methods helps you select the right gouging technique based on factors like material thickness, speed requirements, and equipment availability.

Principles of Arc Gouging

Arc gouging operates by creating a high-temperature electric arc between a carbon electrode and the metal surface, which melts the metal to be removed. The molten metal is then forcibly ejected by a jet of compressed air, allowing for precise and efficient metal removal. Your choice of arc gouging offers faster material removal rates and cleaner cuts compared to oxy-fuel gouging, which relies on burning the metal with oxygen.

Principles of Oxy-Fuel Gouging

Oxy-fuel gouging operates on the principle of using a high-velocity oxygen jet to oxidize and blow away metal, creating precise gouges through controlled burning. This process relies on preheating the metal with a fuel gas flame to reach the ignition temperature before the oxygen stream initiates rapid oxidation. The technique is highly effective for cutting thick metals and removing weld defects due to its ability to produce deep, narrow grooves with minimal heat-affected zones.

Equipment Needed for Each Method

Arc gouging requires a gouging torch, power source (usually a DC or AC arc welder), carbon or steel rods, and appropriate safety gear like helmets and gloves. Oxy-fuel gouging utilizes an oxy-acetylene torch setup, including oxygen and acetylene cylinders, regulators, hoses, a cutting torch with a gouging tip, and protective equipment such as goggles and flame-resistant clothing. Both methods demand specialized equipment tailored to the gouging technique to ensure precision and safety during metal removal.

Types of Materials Best Suited for Each Process

Arc gouging excels in removing hardened steel, cast iron, and high-strength alloys due to its intense localized heat and precision control, making it ideal for heavy-duty industrial applications. Oxy-fuel gouging is better suited for cutting mild steel and thicker, carbon-based materials where slower, controlled oxidation helps create clean gouges without damaging the metal's integrity. Your choice depends on the material's composition and required finish quality, with arc gouging favored for tougher metals and oxy-fuel for more conventional steel types.

Speed and Efficiency Comparison

Arc gouging offers significantly faster metal removal rates, efficiently cutting through thick materials with precise control, making it ideal for large-scale fabrication and repair tasks. Oxy-fuel gouging, while effective for cutting thinner metals, generally operates at a slower pace due to its reliance on slower chemical combustion processes. In industrial applications where speed and high-volume metal removal are critical, arc gouging outperforms oxy-fuel gouging by delivering superior efficiency and reduced operational time.

Quality and Precision of Gouging Results

Arc gouging delivers high-quality, precise gouges with minimal heat-affected zones, making it ideal for intricate metal removal and repair tasks. Oxy-fuel gouging, while effective for thicker materials, often produces wider, less controlled gouges with more thermal distortion. Your choice depends on the required accuracy and finish, as arc gouging offers superior control and cleaner cuts for detailed applications.

Safety Considerations and Hazards

Arc gouging involves intense electric arcs that generate extreme heat and harmful fumes, requiring proper protective gear and adequate ventilation to ensure your safety. Oxy-fuel gouging poses risks of gas leaks, explosions, and intense open flames, necessitating strict adherence to flame arrestor use and gas handling protocols. Both methods demand rigorous safety measures to prevent burns, inhalation hazards, and fire-related accidents in industrial environments.

Cost Analysis: Consumables and Maintenance

Arc gouging generally incurs higher consumable costs due to the frequent replacement of carbon rods and nozzles, while oxy-fuel gouging consumes fuel gases that can be less expensive but may vary based on usage rates. Maintenance for arc gouging equipment tends to be more intensive because of electrode wear and electrical component upkeep, whereas oxy-fuel systems require regular inspection of regulators, hoses, and tips but typically involve lower repair expenses. Evaluating long-term operational costs reveals that oxy-fuel gouging may offer savings in consumables but potentially higher fuel expenses, whereas arc gouging demands higher upfront consumable investment with predictable maintenance cycles.

Choosing the Right Gouging Method for Your Application

Arc gouging offers faster material removal and better precision for thick metals, making it ideal for heavy-duty industrial applications. Oxy-fuel gouging excels in cutting thicker steel sections with lower equipment costs and is more suitable for fieldwork where portability is essential. Your choice depends on project requirements such as material thickness, speed, and available resources to ensure optimal efficiency and quality.

Arc gouging vs oxy-fuel gouging Infographic

libmatt.com

libmatt.com