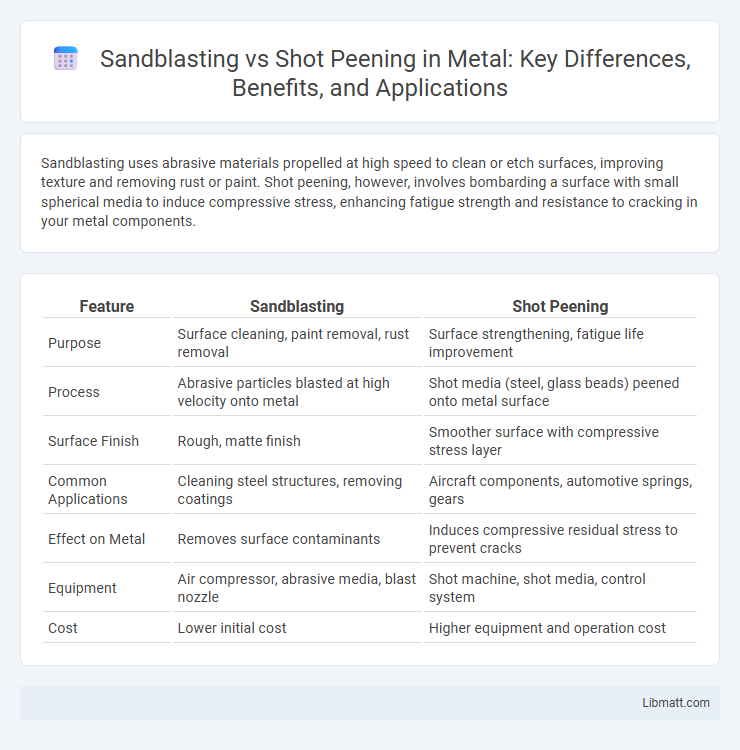

Sandblasting uses abrasive materials propelled at high speed to clean or etch surfaces, improving texture and removing rust or paint. Shot peening, however, involves bombarding a surface with small spherical media to induce compressive stress, enhancing fatigue strength and resistance to cracking in your metal components.

Table of Comparison

| Feature | Sandblasting | Shot Peening |

|---|---|---|

| Purpose | Surface cleaning, paint removal, rust removal | Surface strengthening, fatigue life improvement |

| Process | Abrasive particles blasted at high velocity onto metal | Shot media (steel, glass beads) peened onto metal surface |

| Surface Finish | Rough, matte finish | Smoother surface with compressive stress layer |

| Common Applications | Cleaning steel structures, removing coatings | Aircraft components, automotive springs, gears |

| Effect on Metal | Removes surface contaminants | Induces compressive residual stress to prevent cracks |

| Equipment | Air compressor, abrasive media, blast nozzle | Shot machine, shot media, control system |

| Cost | Lower initial cost | Higher equipment and operation cost |

Introduction to Sandblasting and Shot Peening

Sandblasting and shot peening are surface treatment techniques used to clean, strengthen, or prepare materials like metal and concrete. Sandblasting uses high-pressure abrasive particles to remove rust, paint, and contaminants, improving surface texture for coating adherence. Shot peening, by contrast, propels small spherical media against the surface to induce compressive stress, enhancing fatigue resistance and durability.

Definition and Process Overview

Sandblasting involves propelling fine abrasive particles, typically sand, at high velocity to clean or etch surfaces, effectively removing rust, paint, and debris. Shot peening uses small spherical media, usually steel or ceramic shots, blasted onto metal surfaces to induce beneficial compressive stresses that enhance fatigue resistance and durability. Your choice depends on whether surface cleaning or mechanical strengthening is the primary goal.

Key Equipment Used

Sandblasting utilizes high-pressure air or water to propel abrasive materials like silica sand or aluminum oxide, while shot peening employs a specialized machine that fires small steel, glass, or ceramic beads at metal surfaces. Sandblasting equipment typically includes blast pots, compressors, and blasting nozzles designed for precise cleaning and surface preparation. Your choice depends on whether the goal is surface cleaning with sandblasting or enhancing metal fatigue strength through the compressive stresses induced by shot peening.

Surface Preparation Techniques

Sandblasting and shot peening are surface preparation techniques that enhance material properties by removing contaminants and modifying surface texture. Sandblasting uses abrasive particles propelled at high speed to clean and roughen surfaces, improving coating adhesion and surface uniformity. Shot peening involves impacting the surface with small steel or ceramic beads, inducing compressive stresses that enhance fatigue resistance and durability.

Material Compatibility

Sandblasting is suitable for a wide range of materials including metals, glass, and plastics, but care must be taken with softer materials to avoid surface damage. Shot peening is primarily used on metals and alloys, especially steel and aluminum, as it enhances fatigue resistance by introducing compressive stress without significant material removal. Material compatibility is crucial in selecting the process to ensure surface integrity and desired mechanical properties.

Advantages of Sandblasting

Sandblasting offers precise surface cleaning by effectively removing rust, paint, and contaminants, enhancing surface preparation for coatings or welding. It provides excellent control over blast media size and pressure, allowing tailored finishes for delicate or intricate components without causing surface deformation. Sandblasting is cost-effective and versatile, suitable for various materials such as metal, glass, and concrete, making it ideal for both industrial and decorative applications.

Benefits of Shot Peening

Shot peening enhances the strength and fatigue life of metal components by inducing compressive residual stress on their surfaces, reducing the risk of crack initiation. Unlike sandblasting, shot peening improves resistance to stress corrosion cracking and wear, extending the durability of parts in demanding environments. Your metal parts benefit from this advanced surface treatment by achieving superior performance in aerospace, automotive, and industrial applications.

Common Industrial Applications

Sandblasting is widely used in industrial applications for surface preparation, such as cleaning rust, paint, and scale from metal surfaces before welding or painting. Shot peening is predominantly applied in aerospace, automotive, and manufacturing industries to improve fatigue strength and resistance to stress corrosion in critical components like turbine blades, crankshafts, and structural parts. Both techniques enhance metal surface properties but serve distinct purposes based on the desired outcome in industrial processes.

Safety and Environmental Considerations

Sandblasting and shot peening both require strict safety protocols due to airborne dust and particles; operators must use personal protective equipment such as respirators and protective garments to prevent respiratory and skin hazards. Environmental concerns with sandblasting include silica dust emissions and contaminated wastewater, necessitating dust control systems and proper disposal methods to minimize environmental impact. Shot peening typically generates less hazardous dust but still requires containment measures to protect workers and comply with environmental regulations on particulate matter and noise levels.

Choosing Between Sandblasting and Shot Peening

Choosing between sandblasting and shot peening depends on the desired surface finish and material strength requirements. Sandblasting uses high-pressure abrasive particles to clean or texture surfaces, ideal for paint removal and surface preparation. Shot peening applies small spherical media to induce compressive stress, enhancing fatigue resistance and durability of metal components, making it the preferred option for structural improvements in your projects.

sandblasting vs shot peening Infographic

libmatt.com

libmatt.com