Machining removes material from a workpiece using cutting tools to shape and size it, offering flexibility for various geometries and materials. Grinding, by contrast, uses abrasive wheels to achieve high precision and surface finish, ideal for hard materials and fine tolerances in your manufacturing process.

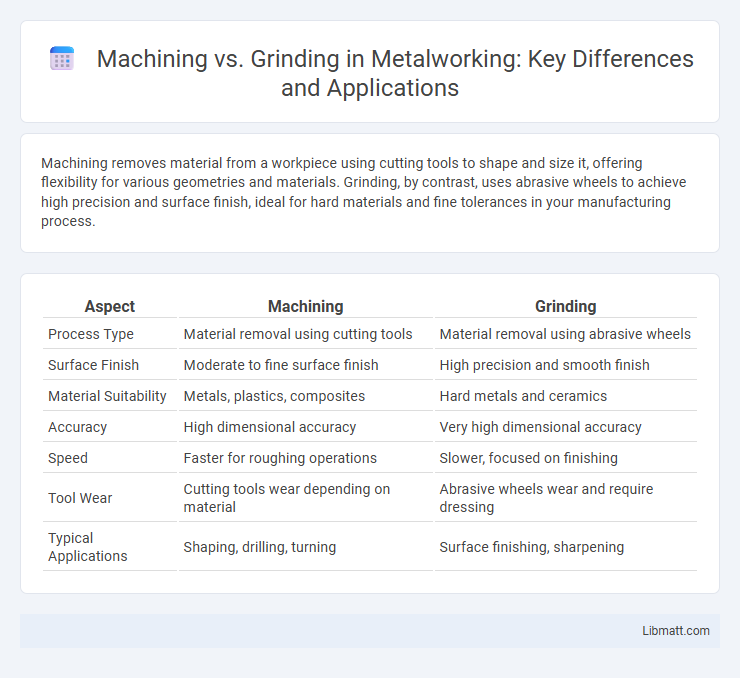

Table of Comparison

| Aspect | Machining | Grinding |

|---|---|---|

| Process Type | Material removal using cutting tools | Material removal using abrasive wheels |

| Surface Finish | Moderate to fine surface finish | High precision and smooth finish |

| Material Suitability | Metals, plastics, composites | Hard metals and ceramics |

| Accuracy | High dimensional accuracy | Very high dimensional accuracy |

| Speed | Faster for roughing operations | Slower, focused on finishing |

| Tool Wear | Cutting tools wear depending on material | Abrasive wheels wear and require dressing |

| Typical Applications | Shaping, drilling, turning | Surface finishing, sharpening |

Introduction to Machining and Grinding

Machining and grinding are essential manufacturing processes utilized to shape and finish materials with precision. Machining involves removing material using cutting tools to create desired shapes, while grinding uses an abrasive wheel to achieve fine surface finishes and tight tolerances. Understanding the differences in techniques and applications helps optimize your production efficiency and product quality.

Key Differences Between Machining and Grinding

Machining involves removing material using cutting tools to shape a workpiece, while grinding relies on abrasive wheels for precision surface finishing and fine material removal. Machining processes typically produce higher material removal rates and are suitable for shaping complex geometries, whereas grinding excels in achieving tight tolerances and superior surface finishes. Understanding these key differences helps you select the most efficient method for your manufacturing needs.

Overview of Machining Processes

Machining processes involve the removal of material from a workpiece using cutting tools to achieve precise shapes and dimensions, commonly including turning, milling, drilling, and boring. These processes offer high flexibility for producing complex geometries and are essential in manufacturing industries such as aerospace, automotive, and electronics. Your choice between machining and grinding depends on factors like material type, required surface finish, and tolerances, with machining excelling in shaping and grinding in fine finishing.

Overview of Grinding Techniques

Grinding techniques encompass surface grinding, cylindrical grinding, and centerless grinding, each designed to achieve precise material removal and smooth finishes. Surface grinding uses a rotating abrasive wheel to produce flat surfaces, while cylindrical grinding targets external or internal cylindrical surfaces with high accuracy. Centerless grinding operates without a spindle, feeding the workpiece between a grinding wheel and a regulating wheel to enhance efficiency in mass production.

Materials Best Suited for Machining vs Grinding

Machining is best suited for softer metals like aluminum, brass, and mild steel, where precise shaping and cutting are required with minimal tool wear. Grinding excels with harder materials such as hardened steel, ceramics, and carbides, providing superior surface finish and tight dimensional tolerances. Your choice between machining and grinding should consider material hardness and desired finish to optimize efficiency and quality.

Precision and Surface Finish Comparison

Machining typically offers high precision with tolerances in the range of microns, making it ideal for creating complex shapes and detailed features. Grinding excels in achieving superior surface finishes, often producing finishes as smooth as 0.1 micrometers Ra, which is critical for parts requiring tight surface quality. Your choice between machining and grinding should depend on the balance needed between dimensional accuracy and surface finish quality.

Cost and Efficiency Considerations

Machining typically offers lower initial setup costs and greater flexibility for varied production runs, while grinding involves higher tool and equipment expenses but delivers superior surface finish and dimensional accuracy. Efficiency in machining depends on material removal rates and tooling durability, whereas grinding excels in precision work with slower material removal rates, impacting cycle time. Evaluating your project's tolerance requirements and production volume will help determine the most cost-effective and efficient process between machining and grinding.

Applications in Modern Manufacturing

Machining and grinding both serve critical roles in modern manufacturing, with machining excelling in shaping complex parts through cutting, drilling, and milling processes, often used for producing prototypes and custom components. Grinding offers superior surface finish and precision, ideal for finishing hard materials like metals and ceramics in automotive and aerospace industries. You can optimize production efficiency by selecting machining for versatile material removal and grinding for achieving tight tolerances and smooth surfaces.

Advantages and Limitations of Each Process

Machining offers high precision and versatility for shaping metal parts with complex geometries but can cause thermal damage and tool wear. Grinding provides superior surface finish and tight dimensional tolerances ideal for hard materials but is slower and less efficient for large material removal. Selecting between machining and grinding depends on factors like material hardness, desired surface quality, and production speed requirements.

Choosing the Right Process for Your Project

Selecting the ideal process between machining and grinding depends on factors like material type, desired surface finish, and tolerance requirements. Machining suits complex shapes and moderate precision, while grinding excels in achieving high dimensional accuracy and superior surface quality. Evaluating project specifications and cost-effectiveness ensures the optimal manufacturing method for your application.

Machining vs grinding Infographic

libmatt.com

libmatt.com