Electro-slag welding (ESW) uses a molten slag to shield the weld, making it ideal for thick materials and vertical welds, while electrogas welding (EGW) employs a protective gas to shield the weld pool, allowing for faster welding on vertical surfaces with minimal spatter. Understanding the differences between ESW and EGW helps you select the most efficient method based on material thickness, weld position, and project requirements.

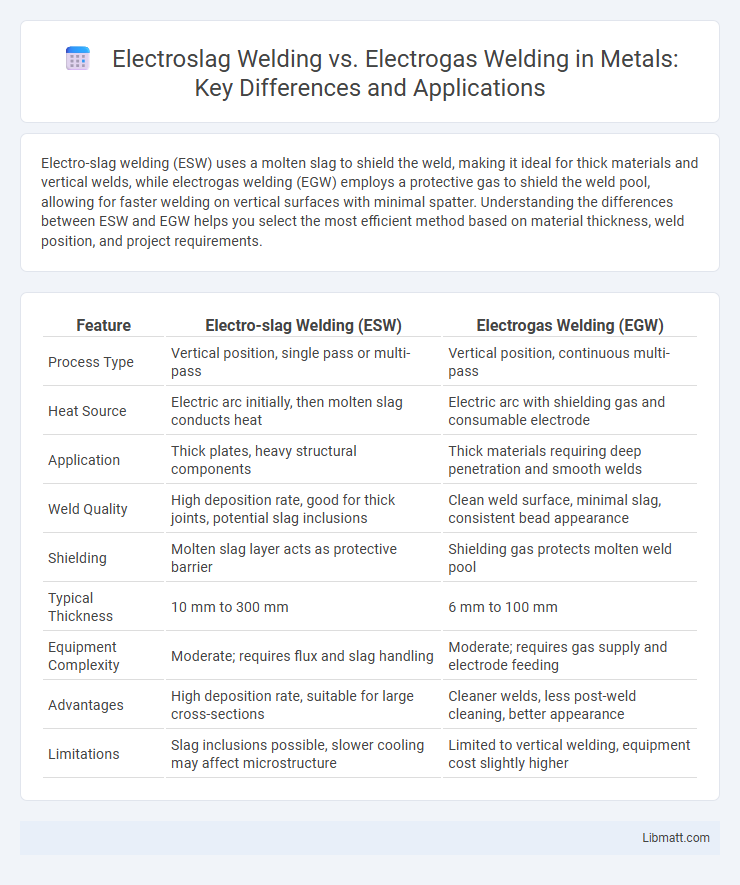

Table of Comparison

| Feature | Electro-slag Welding (ESW) | Electrogas Welding (EGW) |

|---|---|---|

| Process Type | Vertical position, single pass or multi-pass | Vertical position, continuous multi-pass |

| Heat Source | Electric arc initially, then molten slag conducts heat | Electric arc with shielding gas and consumable electrode |

| Application | Thick plates, heavy structural components | Thick materials requiring deep penetration and smooth welds |

| Weld Quality | High deposition rate, good for thick joints, potential slag inclusions | Clean weld surface, minimal slag, consistent bead appearance |

| Shielding | Molten slag layer acts as protective barrier | Shielding gas protects molten weld pool |

| Typical Thickness | 10 mm to 300 mm | 6 mm to 100 mm |

| Equipment Complexity | Moderate; requires flux and slag handling | Moderate; requires gas supply and electrode feeding |

| Advantages | High deposition rate, suitable for large cross-sections | Cleaner welds, less post-weld cleaning, better appearance |

| Limitations | Slag inclusions possible, slower cooling may affect microstructure | Limited to vertical welding, equipment cost slightly higher |

Introduction to Electro-Slag and Electro-Gas Welding

Electro-slag welding (ESW) is a high-productivity welding process used primarily for thick materials, where the heat generated by an electric current passing through a molten slag bath melts the workpieces and filler metal. Electrogas welding (EGW) operates similarly but incorporates a protective shielding gas to stabilize the arc and control the weld pool for vertical or near-vertical joints. Both methods offer deep penetration and efficient heat management, making them suitable for heavy steel fabrication in industries like shipbuilding and construction.

Historical Development and Applications

Electro-slag welding (ESW) was developed in the mid-20th century for joining thick materials in shipbuilding and heavy structural applications, utilizing a molten slag pool to shield the weld. Electrogas welding (EGW), emerging around the same period, is mainly applied in vertical or near-vertical welds of thick steel plates in construction and pressure vessel fabrication. Both processes are highly efficient for large-scale industries, with ESW favored for horizontal joints and EGW for vertical assemblies, reflecting their distinct historical advancements and application scopes.

Fundamental Working Principles

Electro-slag welding (ESW) uses a molten slag pool to shield the weld area, with the heat generated by electrical resistance melting the filler metal and base materials, creating a single-pass weld ideal for thick materials. Electrogas welding (EGW) employs a continuous wire electrode and shielding gas, using electric arc heat to melt the metals, allowing vertical or near-vertical welds with a controlled weld pool. Your choice depends on material thickness and welding position, as ESW suits thick sections while EGW handles vertical joints efficiently.

Equipment and Setup Comparison

Electro-slag welding (ESW) utilizes a heavy copper mold and a water-cooled copper shoe that surrounds the weld joint, requiring a vertical or near-vertical position, while electrogas welding (EGW) employs a continuous consumable wire electrode with a welding head that guides the arc, allowing for more flexible joint positioning. ESW equipment demands a high current power source and a slag system to control the molten slag pool, whereas EGW uses a wire feed mechanism combined with shielding gas to stabilize the arc and protect the weld pool. The setup for ESW typically involves large-scale heavy plates and thick sections, while EGW accommodates various thicknesses with less restrictive joint preparation and faster welding speeds.

Process Parameters and Controls

Electro-slag welding (ESW) operates at higher currents typically between 600 and 1,200 amps, with a slower travel speed controlled to ensure deep penetration and minimal weld defects, while electrogas welding (EGW) uses lower current ranges around 300 to 1,000 amps and faster travel speeds optimized for vertical welding applications. Process parameters in ESW include precise control of slag chemistry and melting rate to maintain a molten slag pool that protects the weld, whereas EGW relies on shielding gas flow rate and electrode wire feed speed to prevent contamination and ensure consistent weld bead shape. Your selection between these methods depends on the required weld thickness, joint configuration, and the necessity for strict control over heat input and welding atmosphere.

Advantages of Electro-Slag Welding

Electro-slag welding (ESW) offers significant advantages such as deep penetration welds and exceptional efficiency for thick materials exceeding 25 mm, reducing the need for multiple passes. Its high deposition rate and minimal distortion make it ideal for heavy steel components used in bridge construction and pressure vessels. ESW also provides superior weld quality with fewer defects compared to electrogas welding (EGW), particularly in maintaining structural integrity under high-stress conditions.

Benefits of Electro-Gas Welding

Electro-Gas Welding (EGW) offers superior vertical welding capabilities compared to Electro-Slag Welding, enabling consistent and high-quality welds on thick materials. Your projects benefit from faster welding speeds and reduced slag inclusions, enhancing productivity and weld integrity. EGW also provides better control over weld penetration and bead shape, making it ideal for heavy fabrication and construction applications.

Limitations and Challenges

Electro-slag welding (ESW) faces limitations including restricted joint design flexibility and being unsuitable for thin materials below 12 mm due to excessive heat input. Electrogas welding (EGW), while offering better adaptability for vertical and overhead positions, encounters challenges with controlling weld pool stability and requires precise shielding gas management to prevent defects. Your choice between ESW and EGW should consider these constraints to optimize weld quality and efficiency for specific applications.

Typical Applications and Industry Usage

Electro-slag welding is predominantly used for thick steel sections in heavy industries such as shipbuilding, bridge construction, and pressure vessel manufacturing, where high deposition rates and deep welds are essential. Electrogas welding finds typical applications in fabrication and repair of pipelines, offshore structures, and railway equipment due to its ability to weld vertical or overhead positions with high-quality weld beads. Your choice between these methods depends on the specific project requirements, including workpiece thickness, welding position, and desired production speed.

Key Differences and Selection Guidelines

Electro-slag welding (ESW) uses a molten slag layer to conduct current and fuse thick materials in vertical or near-vertical positions, making it ideal for heavy steel sections, while electrogas welding (EGW) relies on a continuously fed consumable electrode and shielding gas for vertical welds with faster deposition rates. Key differences include ESW's slower cooling rate which enhances weld quality and reduces defects, versus EGW's faster welding speed ideal for thinner sections and quicker production. When selecting your welding method, consider material thickness, joint orientation, heat input control, and required weld integrity to ensure optimal performance and efficiency.

Electro-slag welding vs electrogas welding Infographic

libmatt.com

libmatt.com