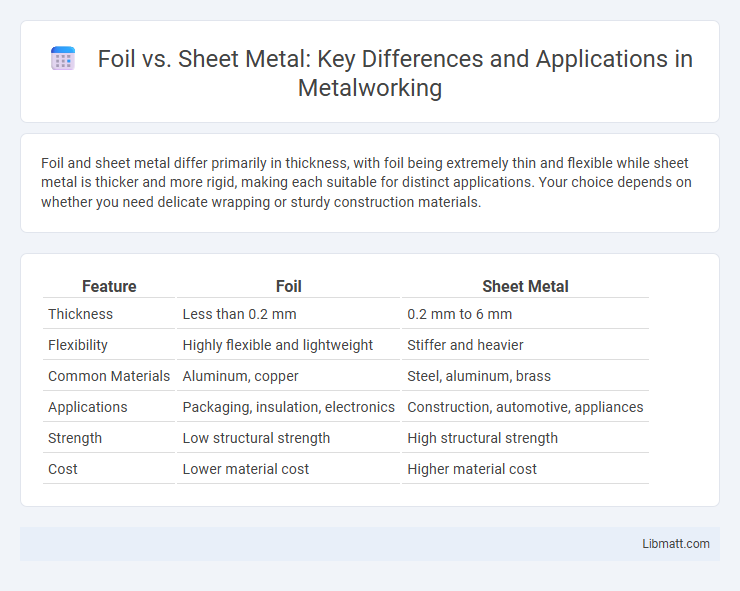

Foil and sheet metal differ primarily in thickness, with foil being extremely thin and flexible while sheet metal is thicker and more rigid, making each suitable for distinct applications. Your choice depends on whether you need delicate wrapping or sturdy construction materials.

Table of Comparison

| Feature | Foil | Sheet Metal |

|---|---|---|

| Thickness | Less than 0.2 mm | 0.2 mm to 6 mm |

| Flexibility | Highly flexible and lightweight | Stiffer and heavier |

| Common Materials | Aluminum, copper | Steel, aluminum, brass |

| Applications | Packaging, insulation, electronics | Construction, automotive, appliances |

| Strength | Low structural strength | High structural strength |

| Cost | Lower material cost | Higher material cost |

Introduction to Foil and Sheet Metal

Foil is an ultra-thin metal product typically less than 0.2 millimeters thick, known for its flexibility and light weight, commonly made from aluminum or copper. Sheet metal, on the other hand, ranges from 0.2 to 6 millimeters in thickness and is used in a wide variety of industries for structural and fabrication purposes due to its rigidity and durability. The primary difference lies in thickness and application, with foil suited for insulation and packaging, while sheet metal is preferred for construction, automotive, and manufacturing components.

Definitions: What is Foil? What is Sheet Metal?

Foil is a very thin and flexible metal material typically less than 0.2 mm thick, commonly made from aluminum or copper, used in applications requiring lightweight and pliable properties such as packaging and insulation. Sheet metal refers to metal formed into sheets generally thicker than foil, ranging from 0.5 mm to several millimeters, used in construction, automotive, and manufacturing industries due to its strength and structural integrity. Both materials are manufactured through rolling or extrusion processes but differ significantly in thickness, flexibility, and typical usage scenarios.

Material Composition Differences

Foil and sheet metal primarily differ in thickness and material composition, with foil being extremely thin and often composed of aluminum or other malleable metals, while sheet metal is thicker and made from a variety of metals such as steel, aluminum, copper, or brass. The foil's thin structure allows for greater flexibility and is typically used for insulation or packaging, whereas sheet metal offers enhanced strength and structural integrity suitable for construction and manufacturing applications. Material composition differences impact properties such as durability, corrosion resistance, and malleability, dictating their optimal use in industrial and domestic environments.

Thickness and Gauge Comparison

Foil is significantly thinner than sheet metal, typically measured in microns, whereas sheet metal gauge varies from 30 to 7 gauge, with lower numbers indicating thicker metal. Foils usually range from 0.006 mm to 0.2 mm in thickness, ideal for applications requiring flexibility and lightweight materials. Your choice depends on the required strength and durability, as sheet metal offers greater structural integrity compared to the delicate nature of foil.

Common Applications of Foil

Foil is commonly used in packaging industries for food preservation and pharmaceutical products due to its excellent barrier properties against moisture, light, and gases. In electronics, aluminum foil serves as shielding material to prevent electromagnetic interference, while in insulation, it reflects heat to improve energy efficiency in buildings. Your choice of foil ensures lightweight protection and flexibility for various industrial and consumer applications.

Common Uses of Sheet Metal

Sheet metal is widely used in the construction industry for roofing, siding, and HVAC ductwork due to its durability and ease of fabrication. Automotive manufacturing relies on sheet metal for body panels, chassis components, and structural parts because of its strength and formability. Appliances, electronics enclosures, and furniture also commonly incorporate sheet metal to provide lightweight, sturdy, and corrosion-resistant solutions.

Manufacturing Processes for Both Materials

Foil manufacturing involves rolling metal to extremely thin gauges, often below 0.2 mm, using cold rolling techniques that enhance surface finish and flexibility. Sheet metal production relies on hot or cold rolling to achieve thicker, structural layers typically ranging from 0.5 mm to several millimeters, allowing for diverse forming and fabrication processes like stamping, bending, and welding. Both materials undergo precise thickness control and surface treatments to meet specific strength, durability, and application requirements in industries such as automotive, aerospace, and packaging.

Strength and Durability Assessment

Sheet metal offers superior strength and durability compared to foil due to its greater thickness and structural integrity, making it ideal for applications requiring high load-bearing capacity. Foil is thin, lightweight, and flexible but lacks the mechanical strength to withstand heavy forces or prolonged wear. Your choice between foil and sheet metal depends on the specific strength requirements and durability needs of your project.

Cost Considerations: Foil vs Sheet Metal

Foil is significantly less expensive than sheet metal due to its thinner gauge and lower material usage, making it ideal for applications requiring minimal strength and weight. Sheet metal, while costlier, offers greater durability and structural integrity, justifying higher expenses in construction, automotive, and industrial projects. Choosing between foil and sheet metal depends on budget constraints, required material performance, and the specific use case.

Choosing the Right Material for Your Project

When choosing between foil and sheet metal for your project, consider the thickness and durability requirements; foil is extremely thin and flexible, ideal for lightweight insulation or decorative applications, while sheet metal offers greater strength and structural support for construction or fabrication tasks. The material properties such as corrosion resistance, thermal conductivity, and ease of shaping directly impact the performance and longevity of your final product. Selecting the right material ensures optimal functionality and cost-efficiency tailored to your specific project needs.

Foil vs sheet metal Infographic

libmatt.com

libmatt.com