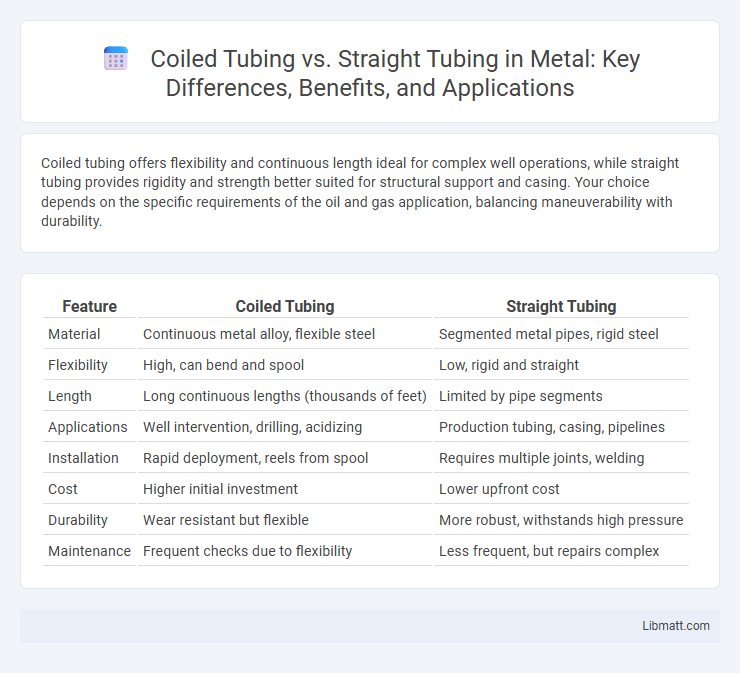

Coiled tubing offers flexibility and continuous length ideal for complex well operations, while straight tubing provides rigidity and strength better suited for structural support and casing. Your choice depends on the specific requirements of the oil and gas application, balancing maneuverability with durability.

Table of Comparison

| Feature | Coiled Tubing | Straight Tubing |

|---|---|---|

| Material | Continuous metal alloy, flexible steel | Segmented metal pipes, rigid steel |

| Flexibility | High, can bend and spool | Low, rigid and straight |

| Length | Long continuous lengths (thousands of feet) | Limited by pipe segments |

| Applications | Well intervention, drilling, acidizing | Production tubing, casing, pipelines |

| Installation | Rapid deployment, reels from spool | Requires multiple joints, welding |

| Cost | Higher initial investment | Lower upfront cost |

| Durability | Wear resistant but flexible | More robust, withstands high pressure |

| Maintenance | Frequent checks due to flexibility | Less frequent, but repairs complex |

Introduction to Coiled Tubing and Straight Tubing

Coiled tubing consists of continuous, flexible steel tubing wound on a reel, enabling efficient deployment in well intervention and drilling operations without joints or connections. Straight tubing, typically composed of rigid, jointed steel segments, is used primarily for casing and tubing strings in well construction, offering structural support and pressure containment. Both types serve critical roles in oil and gas extraction, with coiled tubing favored for its flexibility and rapid deployment, while straight tubing provides strength and integrity in wellbores.

Key Differences Between Coiled Tubing and Straight Tubing

Coiled tubing is a continuous length of flexible steel used for well intervention without the need to connect individual segments, whereas straight tubing consists of rigid, connected jointed pipes primarily used during initial well construction. Coiled tubing offers advantages in operational efficiency and real-time deployment, while straight tubing provides greater structural strength and is better suited for high-pressure environments. Understanding these key differences helps you choose the appropriate tubing type based on specific well conditions and project requirements.

Applications of Coiled Tubing

Coiled tubing is extensively used in well intervention, drilling, and completion operations due to its flexibility and continuous length, enabling work in live wells without shutting down production. Its applications include cleanouts, acidizing, fracturing, and logging, where maneuverability and rapid deployment are critical. Choosing coiled tubing for your project enhances efficiency in complex well environments compared to traditional straight tubing.

Applications of Straight Tubing

Straight tubing is commonly used in applications requiring precise, rigid structures such as hydraulic lines, pneumatic systems, and medical devices. Its consistent shape makes it ideal for transporting fluids or gases under high pressure without deformation, ensuring accuracy and reliability. You benefit from straight tubing in scenarios where predictable flow and structural integrity are critical.

Advantages of Coiled Tubing

Coiled tubing offers continuous length without joints, enabling faster deployment and reducing rig time compared to straight tubing sections. Its flexibility allows for operations in highly deviated wells and complex well geometries that straight tubing cannot access easily. The enhanced real-time intervention capability with coiled tubing improves well maintenance efficiency and reduces operational risks.

Advantages of Straight Tubing

Straight tubing offers superior strength and durability compared to coiled tubing, making it ideal for high-pressure and high-temperature applications in oil and gas wells. Its rigid structure enables precise directional control and efficient mechanical operations such as logging and perforating. Straight tubing also simplifies maintenance and inspection, reducing downtime and operational costs.

Limitations of Coiled Tubing

Coiled tubing faces limitations such as restricted reach in highly deviated or extended-reach wells due to its continuous length and flexibility constraints. It is less effective in high-pressure and high-temperature environments compared to straight tubing, which offers greater structural integrity. Wear and fatigue issues also limit coiled tubing's operational lifespan, necessitating frequent inspections and replacements.

Limitations of Straight Tubing

Straight tubing presents limitations such as reduced flexibility, making it challenging to navigate complex wellbore trajectories or highly deviated wells. Its rigid structure increases the risk of damage or failure under high-pressure and abrasive conditions common in oil and gas operations. Understanding these constraints helps you select coiled tubing for enhanced maneuverability and operational efficiency in demanding environments.

Cost Comparison: Coiled Tubing vs Straight Tubing

Coiled tubing typically incurs higher initial costs due to specialized equipment and continuous length benefits, reducing connection points and operational downtime. Straight tubing, while generally more affordable upfront, involves increased labor and additional fittings for connections, potentially raising overall expenditures. Evaluating your project's scale and complexity will help determine which tubing option delivers the best cost efficiency.

Choosing the Right Tubing for Your Project

Selecting the appropriate tubing depends on the specific requirements of your project, such as flexibility, length, and pressure tolerance. Coiled tubing offers continuous lengths without joints, ideal for applications needing quick deployment and reduced downtime, while straight tubing provides superior rigidity and strength for high-pressure or structural purposes. Understanding the operational environment and performance criteria ensures you choose tubing that optimizes efficiency and durability.

Coiled tubing vs straight tubing Infographic

libmatt.com

libmatt.com