Austenite is a face-centered cubic structure known for its high toughness and ductility at elevated temperatures, while martensite is a hard, brittle body-centered tetragonal phase formed by rapid quenching, offering superior strength and hardness. Your choice between the two depends on whether you prioritize malleability or maximum hardness in steel applications.

Table of Comparison

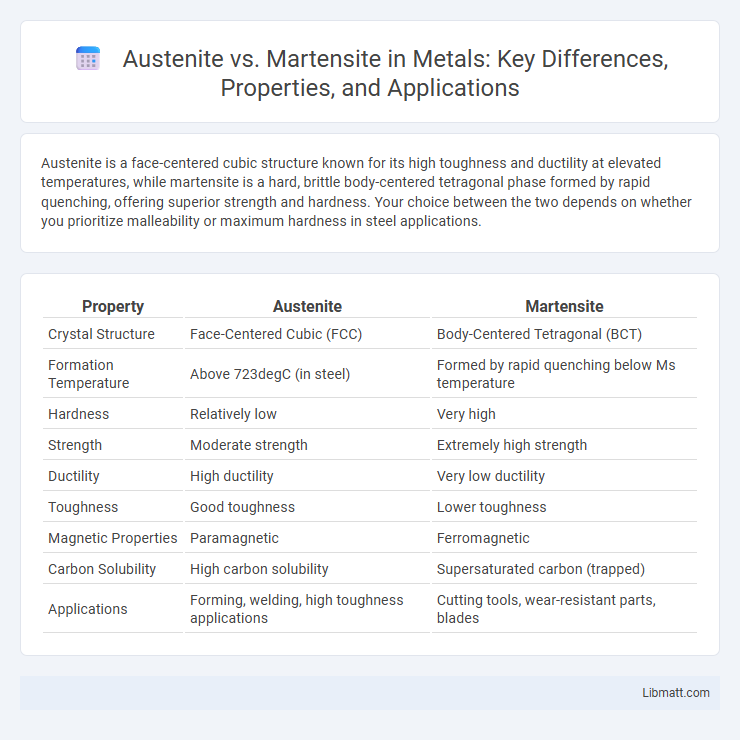

| Property | Austenite | Martensite |

|---|---|---|

| Crystal Structure | Face-Centered Cubic (FCC) | Body-Centered Tetragonal (BCT) |

| Formation Temperature | Above 723degC (in steel) | Formed by rapid quenching below Ms temperature |

| Hardness | Relatively low | Very high |

| Strength | Moderate strength | Extremely high strength |

| Ductility | High ductility | Very low ductility |

| Toughness | Good toughness | Lower toughness |

| Magnetic Properties | Paramagnetic | Ferromagnetic |

| Carbon Solubility | High carbon solubility | Supersaturated carbon (trapped) |

| Applications | Forming, welding, high toughness applications | Cutting tools, wear-resistant parts, blades |

Introduction to Austenite and Martensite

Austenite is a face-centered cubic (FCC) phase of iron and steel formed at high temperatures, known for its ductility and ability to dissolve carbon. Martensite is a body-centered tetragonal (BCT) phase produced by the rapid quenching of austenite, characterized by its hardness and brittleness due to trapped carbon atoms. The transformation from austenite to martensite is diffusionless, resulting in significant changes in mechanical properties used in heat treatment processes.

Crystal Structure Differences

Austenite exhibits a face-centered cubic (FCC) crystal structure, which provides high ductility and toughness due to its symmetric atomic arrangement. Martensite, in contrast, has a body-centered tetragonal (BCT) crystal structure formed by rapid quenching, resulting in a hard and brittle phase with distorted lattice parameters. The transformation from FCC to BCT during cooling significantly influences the mechanical properties and phase stability of steel.

Formation and Transformation Processes

Austenite forms at high temperatures in steel when the crystal structure changes to a face-centered cubic (FCC) arrangement, allowing for greater carbon solubility. Martensite results from the rapid quenching of austenite, causing a diffusionless transformation into a body-centered tetragonal (BCT) structure, which traps carbon atoms in place. Understanding these transformation processes helps optimize your heat treatment to achieve desired mechanical properties like hardness and strength.

Mechanical Properties Comparison

Austenite exhibits high ductility and moderate strength due to its face-centered cubic (FCC) crystal structure, enabling it to absorb significant energy before deformation. Martensite, formed by rapid quenching, has a body-centered tetragonal (BCT) structure that imparts exceptional hardness and tensile strength but makes it much more brittle. The mechanical properties contrast highlights austenite's toughness versus martensite's superior hardness, influencing their applications in demanding environments like automotive and aerospace industries.

Thermal Stability and Heat Treatment

Austenite exhibits higher thermal stability compared to martensite, maintaining its face-centered cubic (FCC) structure at elevated temperatures, which allows for effective heat treatments such as annealing and normalizing. Martensite forms through rapid quenching and is metastable, characterized by a body-centered tetragonal (BCT) structure that transforms upon heating, requiring tempering to enhance toughness and reduce brittleness. Understanding these differences enables you to select optimal heat treatment processes to achieve desired mechanical properties in steel.

Magnetic Properties

Austenite is generally paramagnetic due to its face-centered cubic (FCC) crystal structure, exhibiting weak magnetic susceptibility only under strong external magnetic fields. Martensite, formed by rapid cooling of austenite, has a body-centered tetragonal (BCT) structure that enhances ferromagnetic behavior, making it strongly magnetic. The magnetic difference between austenite and martensite is critical in applications such as magnetic shape memory alloys and non-destructive testing of steel phases.

Applications in Industry

Austenite's high toughness and corrosion resistance make it ideal for use in stainless steel manufacturing, particularly in chemical processing and food industry equipment. Martensite, known for its exceptional hardness and strength, is widely applied in cutting tools, automotive components, and wear-resistant machinery parts. Your choice between austenite and martensite will depend on the required balance of mechanical properties and environmental conditions specific to your industrial application.

Microstructural Characterization

Austenite exhibits a face-centered cubic (FCC) lattice structure that allows for higher ductility and toughness, characterized by its relatively uniform grain morphology observable under optical microscopy. Martensite presents a body-centered tetragonal (BCT) lattice formed via diffusionless transformation from austenite, displaying a needle-like or plate-like microstructure visible through scanning electron microscopy. These distinct microstructures directly influence mechanical properties, with martensite offering high hardness and strength due to its distorted lattice and carbon trapping effects.

Corrosion Resistance Comparison

Austenite exhibits superior corrosion resistance compared to martensite due to its stable face-centered cubic (FCC) crystal structure and higher chromium and nickel content, which form a protective oxide layer against corrosion. Martensite, with its body-centered tetragonal (BCT) structure and lower alloying elements, is more susceptible to rust and pitting in harsh environments. Choosing austenitic stainless steel enhances your material's durability and longevity in corrosive conditions.

Summary of Key Differences

Austenite is a face-centered cubic (FCC) phase of iron characterized by its ductility and ability to dissolve carbon, while martensite is a body-centered tetragonal (BCT) phase known for its hardness and brittleness due to trapped carbon atoms. Austenite forms at high temperatures, typically above 727degC in steel, whereas martensite results from rapid quenching of austenite, causing a diffusionless transformation. The key differences lie in their crystal structure, mechanical properties, carbon solubility, and formation processes, which directly impact steel's strength and toughness.

Austenite vs martensite Infographic

libmatt.com

libmatt.com