Solution annealing involves heating a metal to a high temperature followed by rapid cooling to dissolve precipitates and homogenize the microstructure, enhancing strength and corrosion resistance. Stress relieving, on the other hand, heats metal to a lower temperature to reduce residual stresses without significantly altering the microstructure or mechanical properties.

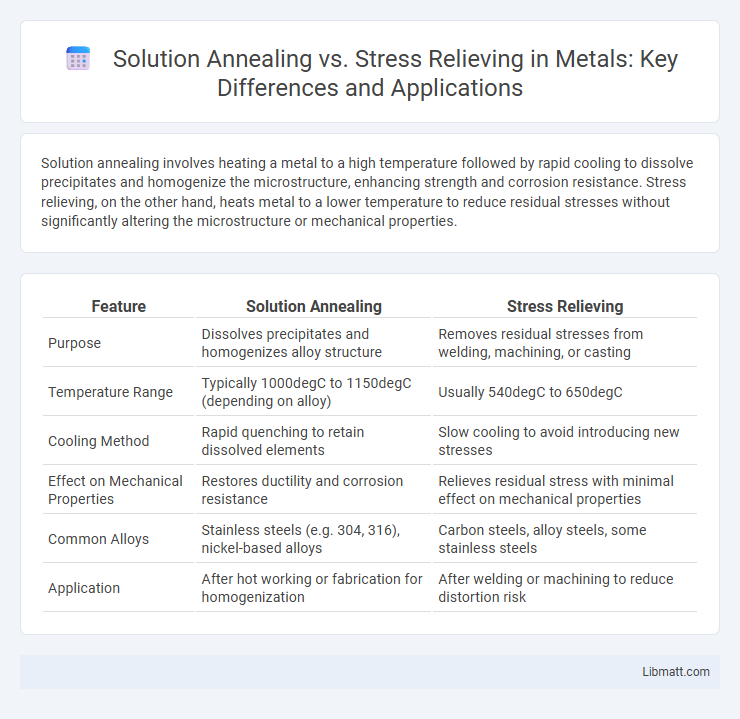

Table of Comparison

| Feature | Solution Annealing | Stress Relieving |

|---|---|---|

| Purpose | Dissolves precipitates and homogenizes alloy structure | Removes residual stresses from welding, machining, or casting |

| Temperature Range | Typically 1000degC to 1150degC (depending on alloy) | Usually 540degC to 650degC |

| Cooling Method | Rapid quenching to retain dissolved elements | Slow cooling to avoid introducing new stresses |

| Effect on Mechanical Properties | Restores ductility and corrosion resistance | Relieves residual stress with minimal effect on mechanical properties |

| Common Alloys | Stainless steels (e.g. 304, 316), nickel-based alloys | Carbon steels, alloy steels, some stainless steels |

| Application | After hot working or fabrication for homogenization | After welding or machining to reduce distortion risk |

Introduction to Solution Annealing and Stress Relieving

Solution annealing involves heating stainless steel to a high temperature, typically between 1,900degF and 2,100degF, followed by rapid cooling to dissolve carbides and homogeneously redistribute alloying elements, enhancing corrosion resistance and mechanical properties. Stress relieving is performed at lower temperatures, usually between 1,100degF and 1,300degF, to reduce residual stresses induced by welding or machining without significantly altering the metal's microstructure. Both heat treatment processes are essential in controlling material performance, with solution annealing aimed at restoring a fully austenitic phase, while stress relieving focuses on minimizing internal stresses to prevent distortion and cracking.

Definition and Purpose of Solution Annealing

Solution annealing is a heat treatment process that involves heating an alloy, typically stainless steel, to a high temperature followed by rapid cooling to dissolve precipitates and create a uniform solid solution. Its primary purpose is to restore the material's corrosion resistance, enhance mechanical properties, and homogenize the microstructure by eliminating segregations and carbide precipitates. Unlike stress relieving, which aims to reduce residual stresses without altering the microstructure significantly, solution annealing fundamentally modifies the alloy's phase composition to improve performance.

Definition and Purpose of Stress Relieving

Stress relieving is a heat treatment process aimed at reducing residual stresses in metal components without significantly altering their microstructure or mechanical properties. Unlike solution annealing, which dissolves alloying elements to create a homogeneous phase, stress relieving involves heating the material to a lower temperature and then cooling it slowly to minimize internal stresses caused by welding, machining, or forming. Your components benefit from stress relieving by improving dimensional stability and reducing the risk of distortion or cracking in subsequent manufacturing steps.

Key Differences Between Solution Annealing and Stress Relieving

Solution annealing involves heating a metal, usually stainless steel, to a high temperature followed by rapid cooling to dissolve precipitates and restore a homogeneous microstructure for enhanced corrosion resistance and mechanical properties. Stress relieving, performed at lower temperatures, aims to reduce internal stresses induced by prior manufacturing processes without significantly altering the metal's microstructure or mechanical characteristics. The key difference lies in solution annealing's ability to modify the metal's microstructure and properties, whereas stress relieving primarily alleviates residual stresses while maintaining the original material structure.

Metallurgical Processes Involved in Solution Annealing

Solution annealing involves heating an alloy, typically stainless steel or aluminum, to a high temperature where alloying elements dissolve into a single-phase solid solution, thereby eliminating precipitates and homogenizing the microstructure. This metallurgical process enhances corrosion resistance and mechanical properties by enabling a uniform distribution of solute atoms and preventing the formation of brittle phases. Stress relieving, by contrast, operates at lower temperatures to reduce residual stresses without significantly altering the microstructure or dissolving precipitates, making solution annealing crucial for restoring the material's structural integrity at the atomic level.

Metallurgical Processes Involved in Stress Relieving

Stress relieving involves heating metal to a lower temperature, typically between 550degC and 650degC, to reduce residual stresses without altering the metallurgical structure significantly. This process allows atomic diffusion to relieve internal stresses caused by prior manufacturing operations like welding or machining. Your components benefit from enhanced dimensional stability and reduced risk of stress-corrosion cracking, preserving mechanical properties while minimizing distortion.

Applications of Solution Annealing Across Industries

Solution annealing is widely applied in aerospace for enhancing the corrosion resistance and mechanical properties of stainless steel components, ensuring durability in extreme environments. In the chemical processing industry, this heat treatment improves the ductility and toughness of alloys used in reactors and piping systems exposed to high temperatures and aggressive chemicals. The automotive sector benefits from solution annealing by optimizing the formability and strength of stainless steel parts, contributing to lightweight vehicle construction and improved fuel efficiency.

Applications of Stress Relieving Across Industries

Stress relieving is widely used across industries such as aerospace, automotive, and construction to reduce residual stresses from welding, machining, or casting, enhancing the durability and performance of critical components. This process prevents distortion and cracking in metal parts, ensuring reliability in applications ranging from pressure vessels to structural steel frameworks. Your choice of stress-relieving techniques directly impacts product quality and service life in demanding industrial environments.

Advantages and Limitations of Solution Annealing vs. Stress Relieving

Solution annealing offers the advantage of dissolving precipitates and homogenizing the microstructure, resulting in enhanced corrosion resistance and mechanical properties, particularly in stainless steels and superalloys. Stress relieving primarily reduces residual stresses without significantly altering the microstructure, preserving dimensional stability but providing less improvement in mechanical strength compared to solution annealing. Limitations of solution annealing include higher energy consumption and potential distortion due to higher processing temperatures, whereas stress relieving may be insufficient for applications requiring significant microstructural changes or complete stress elimination.

Choosing the Right Heat Treatment: Solution Annealing or Stress Relieving

Choosing the right heat treatment depends on your material's composition and application requirements, with solution annealing suited for stainless steels and aluminum alloys to dissolve precipitates and enhance corrosion resistance, while stress relieving reduces residual stresses in welded or machined parts without altering microstructure. Solution annealing involves heating to a high temperature followed by rapid cooling, optimizing mechanical properties and corrosion resistance, whereas stress relieving uses lower temperatures to prevent distortion and improve dimensional stability. Understanding these differences helps you select the most effective process for extending component life and ensuring performance.

Solution annealing vs stress relieving Infographic

libmatt.com

libmatt.com