Zinc-nickel plating offers superior corrosion resistance and environmental friendliness compared to cadmium plating, which is known for its excellent lubricity and electrical conductivity but poses significant toxicity concerns. Your choice should balance performance needs with environmental regulations and safety considerations.

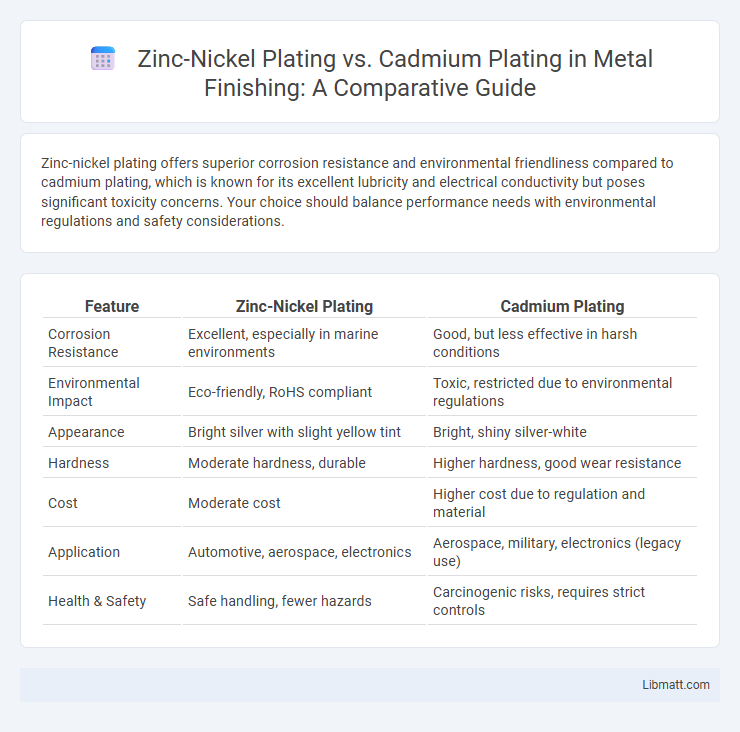

Table of Comparison

| Feature | Zinc-Nickel Plating | Cadmium Plating |

|---|---|---|

| Corrosion Resistance | Excellent, especially in marine environments | Good, but less effective in harsh conditions |

| Environmental Impact | Eco-friendly, RoHS compliant | Toxic, restricted due to environmental regulations |

| Appearance | Bright silver with slight yellow tint | Bright, shiny silver-white |

| Hardness | Moderate hardness, durable | Higher hardness, good wear resistance |

| Cost | Moderate cost | Higher cost due to regulation and material |

| Application | Automotive, aerospace, electronics | Aerospace, military, electronics (legacy use) |

| Health & Safety | Safe handling, fewer hazards | Carcinogenic risks, requires strict controls |

Introduction to Zinc-Nickel and Cadmium Plating

Zinc-nickel plating offers enhanced corrosion resistance and superior hardness compared to traditional cadmium plating, making it a preferred choice in aerospace, automotive, and marine industries. Cadmium plating provides excellent lubricity and protection against galvanic corrosion but faces regulatory restrictions due to its environmental and health hazards. Your decision between zinc-nickel and cadmium plating should consider performance requirements, environmental compliance, and application-specific needs.

Chemical Composition and Process Overview

Zinc-nickel plating involves an alloy coating primarily composed of zinc and 12-15% nickel, applied through an electroplating process that enhances corrosion resistance and mechanical properties. Cadmium plating consists of a cadmium metal layer deposited via electrochemical methods, renowned for excellent corrosion resistance and lubricity but limited by toxicity concerns. Both processes require precise bath chemistry control, with zinc-nickel baths typically containing zinc sulfate and nickel sulfate, whereas cadmium plating uses cadmium salts, influencing their respective thickness, adhesion, and environmental impact.

Corrosion Resistance Comparison

Zinc-nickel plating offers superior corrosion resistance compared to cadmium plating, especially in harsh environments such as marine and industrial atmospheres. While cadmium plating provides good protection, zinc-nickel coatings demonstrate enhanced durability and longer lifespan under salt spray testing, often exceeding 1000 hours without white rust formation. You benefit from zinc-nickel plating's eco-friendly and RoHS-compliant properties, making it a preferred choice over cadmium plating in modern corrosion protection applications.

Environmental and Regulatory Considerations

Zinc-nickel plating offers superior environmental benefits compared to cadmium plating, as it avoids the use of highly toxic cadmium, which is restricted under global regulations like REACH and RoHS. Your choice of zinc-nickel plating aligns better with stringent environmental standards, reducing hazardous waste and minimizing ecological impact. Regulatory agencies increasingly favor zinc-nickel plating for its corrosion resistance without harmful cadmium byproducts, making it a safer and more sustainable alternative.

Mechanical Properties and Durability

Zinc-nickel plating offers superior mechanical properties compared to cadmium plating, including higher hardness and improved corrosion resistance, making it ideal for heavy-duty applications. Its durability in harsh environments surpasses cadmium plating, which tends to degrade faster under extreme conditions and offers limited protection against wear and tear. Your choice should favor zinc-nickel plating for long-lasting performance and enhanced protection in demanding mechanical applications.

Applications in Industry

Zinc-nickel plating is widely used in automotive, aerospace, and electronics industries due to its superior corrosion resistance and environmental compliance compared to cadmium plating. Cadmium plating remains prevalent in aerospace and military applications where extreme corrosion protection and lubricity at low temperatures are critical. Industry trends favor zinc-nickel plating as a sustainable alternative, especially for protective coatings on fasteners, gears, and structural components exposed to harsh environments.

Cost Effectiveness and Availability

Zinc-nickel plating offers superior cost effectiveness compared to cadmium plating due to lower material costs and reduced environmental compliance expenses. It is widely available as a non-toxic, RoHS-compliant alternative, making it easier for manufacturers to source and use without regulatory restrictions. Your choice of zinc-nickel plating ensures both economical benefits and accessibility in various industrial applications.

Health and Safety Implications

Zinc-nickel plating offers significantly lower health risks compared to cadmium plating, as cadmium is highly toxic and carcinogenic, posing severe inhalation and dermal hazards to workers. The shift towards zinc-nickel plating reduces exposure to hazardous heavy metals and complies with stricter environmental regulations, such as RoHS and REACH directives. Effective ventilation and protective equipment remain essential to mitigate risks in both plating processes.

Lifespan and Maintenance Requirements

Zinc-nickel plating offers superior corrosion resistance and a longer lifespan than cadmium plating, often lasting over 2,000 hours in salt spray tests compared to cadmium's 500-1,000 hours. Maintenance for zinc-nickel coatings is minimal due to their self-passivating properties, reducing the need for frequent reapplications and environmental compliance efforts. Cadmium plating requires more regular upkeep because it is prone to flaking and environmental regulations limit its use, especially in aerospace and military sectors.

Choosing the Right Plating for Your Needs

Zinc-nickel plating offers superior corrosion resistance and environmental benefits compared to cadmium plating, making it ideal for aerospace, automotive, and marine applications where durability and eco-friendliness matter. Cadmium plating provides excellent conductivity and solderability but poses environmental and health risks due to its toxic nature, leading to stricter regulations and restricted use. Your choice should weigh performance requirements, regulatory compliance, and environmental impact to select the plating that best suits your specific application.

Zinc-nickel plating vs cadmium plating Infographic

libmatt.com

libmatt.com