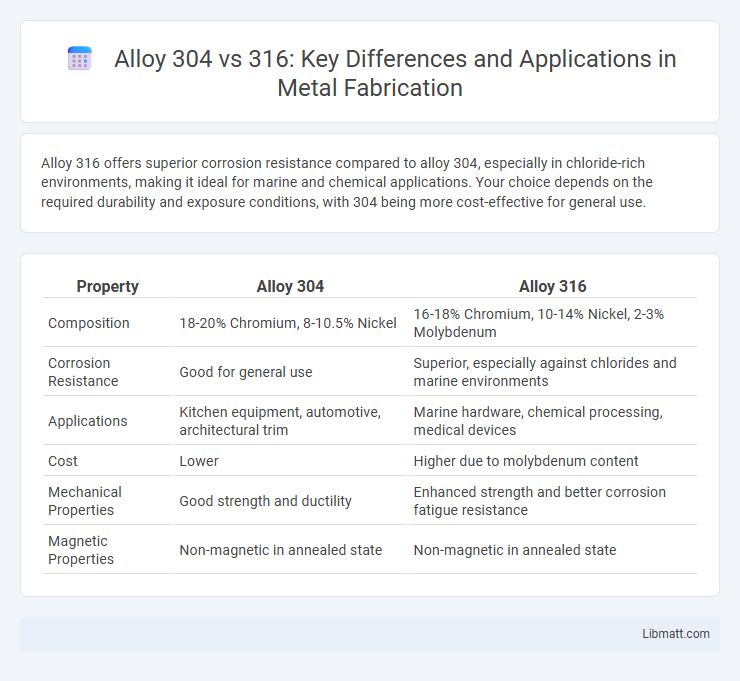

Alloy 316 offers superior corrosion resistance compared to alloy 304, especially in chloride-rich environments, making it ideal for marine and chemical applications. Your choice depends on the required durability and exposure conditions, with 304 being more cost-effective for general use.

Table of Comparison

| Property | Alloy 304 | Alloy 316 |

|---|---|---|

| Composition | 18-20% Chromium, 8-10.5% Nickel | 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum |

| Corrosion Resistance | Good for general use | Superior, especially against chlorides and marine environments |

| Applications | Kitchen equipment, automotive, architectural trim | Marine hardware, chemical processing, medical devices |

| Cost | Lower | Higher due to molybdenum content |

| Mechanical Properties | Good strength and ductility | Enhanced strength and better corrosion fatigue resistance |

| Magnetic Properties | Non-magnetic in annealed state | Non-magnetic in annealed state |

Introduction to Stainless Steel Alloys

Stainless steel alloys 304 and 316 are among the most commonly used materials in various industries due to their excellent corrosion resistance and durability. Alloy 304 contains 18-20% chromium and 8-10.5% nickel, making it suitable for general-purpose applications, while 316 includes 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, enhancing its resistance to chlorides and marine environments. Choosing between alloy 304 and 316 depends on Your specific requirements for corrosion resistance and environmental exposure.

Chemical Composition: 304 vs 316

Alloy 304 primarily consists of 18-20% chromium and 8-10.5% nickel, while alloy 316 contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which enhances corrosion resistance. Your choice between 304 and 316 will impact chemical stability, with 316 offering superior resistance to chlorides and marine environments due to the molybdenum content.

Corrosion Resistance Comparison

Alloy 316 offers superior corrosion resistance compared to Alloy 304 due to its higher molybdenum content, which enhances protection against chloride and marine environments. You will find Alloy 304 performs well against oxidizing agents but is less effective in saltwater or acidic conditions. Choosing Alloy 316 ensures better durability and longevity in harsh, corrosive settings, especially in chemical processing or coastal applications.

Mechanical Properties and Strength

Alloy 304 exhibits a tensile strength of approximately 505 MPa and a yield strength of around 215 MPa, suitable for general industrial applications requiring moderate mechanical performance. Alloy 316 offers enhanced mechanical properties with a tensile strength near 579 MPa and yield strength close to 290 MPa, providing superior strength and corrosion resistance in harsh environments. The higher nickel and molybdenum content in 316 alloy contributes to its improved toughness and resistance to pitting, making it ideal for marine and chemical processing applications.

Cost Differences Between 304 and 316

Alloy 304 stainless steel is generally more cost-effective compared to 316 due to its lower nickel and molybdenum content, making it suitable for applications with less corrosive environments. The presence of molybdenum in 316 significantly increases production costs, reflecting its enhanced corrosion resistance, especially against chlorides and marine exposure. In budgeting for stainless steel projects, choosing 304 can reduce initial material expenses, while 316, though pricier, offers greater durability in harsh conditions, potentially lowering long-term maintenance costs.

Applications and Industry Usage

Alloy 304 is widely used in food processing, kitchen equipment, and architectural applications due to its excellent corrosion resistance and formability. Alloy 316 is preferred in marine, chemical processing, and pharmaceutical industries where superior resistance to chloride and harsh environments is crucial. The enhanced molybdenum content in 316 provides improved durability against pitting and crevice corrosion, making it ideal for aggressive industrial applications.

Heat and Temperature Resistance

Alloy 316 exhibits superior heat and temperature resistance compared to Alloy 304 due to its higher molybdenum content, which enhances its ability to withstand corrosive environments at elevated temperatures. 316 stainless steel can maintain structural integrity at temperatures up to approximately 870degC (1600degF), making it ideal for applications involving high heat exposure. You should choose Alloy 316 over 304 when corrosion resistance at higher temperatures is critical to your project's performance.

Weldability and Fabrication

Alloy 304 offers excellent weldability and is easier to fabricate due to its lower molybdenum content, making it suitable for general-purpose applications. Alloy 316 contains higher molybdenum, providing superior corrosion resistance but requiring more controlled welding techniques to prevent weld decay and maintain structural integrity. Both alloys respond well to common fabrication methods, though 316 often necessitates post-weld heat treatment to optimize performance in harsh environments.

Maintenance and Longevity

Alloy 316 offers superior corrosion resistance compared to alloy 304 due to its molybdenum content, making it ideal for harsh environments and reducing maintenance frequency. Alloy 304 requires more regular upkeep to prevent rust and degradation in saline or acidic conditions, impacting longevity. The extended lifespan of alloy 316 in industrial applications results in lower long-term maintenance costs and improved durability.

Choosing the Right Alloy: 304 or 316

Choosing between alloy 304 and 316 depends on your application's exposure to corrosive environments; 316 stainless steel offers superior corrosion resistance due to its molybdenum content, making it ideal for marine or chemical settings. Alloy 304 is more cost-effective and performs well in general indoor environments or less aggressive conditions. Understanding the specific environmental factors and budget constraints will guide you to the right alloy choice for durability and performance.

alloy 304 vs 316 Infographic

libmatt.com

libmatt.com