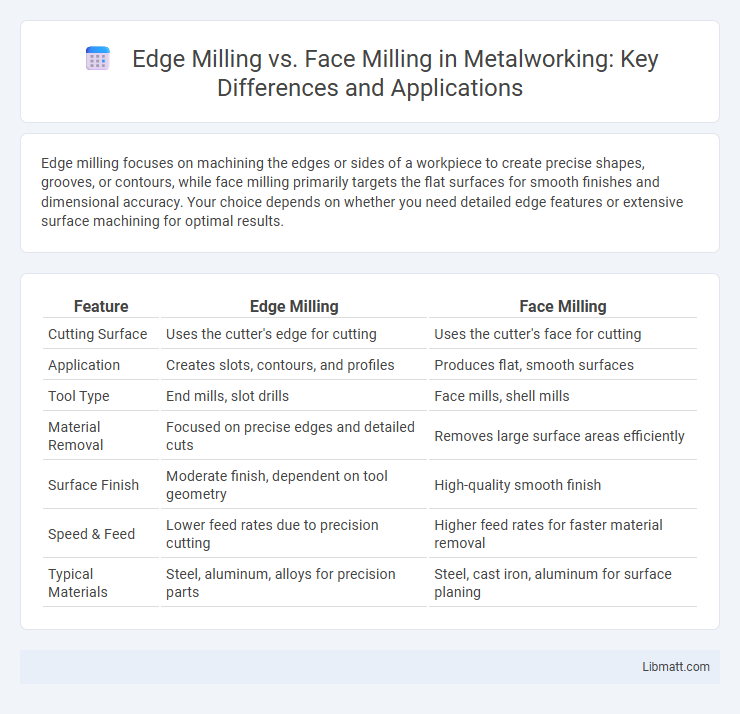

Edge milling focuses on machining the edges or sides of a workpiece to create precise shapes, grooves, or contours, while face milling primarily targets the flat surfaces for smooth finishes and dimensional accuracy. Your choice depends on whether you need detailed edge features or extensive surface machining for optimal results.

Table of Comparison

| Feature | Edge Milling | Face Milling |

|---|---|---|

| Cutting Surface | Uses the cutter's edge for cutting | Uses the cutter's face for cutting |

| Application | Creates slots, contours, and profiles | Produces flat, smooth surfaces |

| Tool Type | End mills, slot drills | Face mills, shell mills |

| Material Removal | Focused on precise edges and detailed cuts | Removes large surface areas efficiently |

| Surface Finish | Moderate finish, dependent on tool geometry | High-quality smooth finish |

| Speed & Feed | Lower feed rates due to precision cutting | Higher feed rates for faster material removal |

| Typical Materials | Steel, aluminum, alloys for precision parts | Steel, cast iron, aluminum for surface planing |

Introduction to Edge Milling and Face Milling

Edge milling involves cutting along the edges of a workpiece to create precise profiles, grooves, or slots, making it ideal for detailed contour shaping. Face milling removes material from the flat surface or face of a workpiece, producing smooth, flat finishes and achieving high material removal rates. Both techniques utilize different cutter orientations and tooling to optimize machining efficiency and surface quality for various manufacturing applications.

Definition and Key Differences

Edge milling involves cutting along the edges of a workpiece to create contours, slots, or grooves, using the periphery of the milling cutter. Face milling, on the other hand, uses the cutter's face to produce flat surfaces or finishes on the workpiece by removing material from the top. Understanding these key differences helps you select the appropriate milling technique based on the desired surface finish and part geometry.

Applications of Edge Milling

Edge milling is primarily used for creating precise grooves, slots, and contours on the edges of workpieces, making it ideal for applications requiring detailed profiling and shaping. This machining process excels in tool and die making, aerospace component fabrication, and manufacturing intricate parts with tight tolerances, where accurate edge finishes are critical. Your choice of edge milling enhances the precision and surface quality needed for complex edge geometries that face milling cannot efficiently achieve.

Applications of Face Milling

Face milling is primarily used for creating flat surfaces, such as machining large, horizontal planes on castings or plates, ensuring smooth finishes and precise dimensions. It excels in removing large amounts of material quickly, making it ideal for preparing surfaces before finishing. This process is commonly applied in industries like automotive and aerospace for surface flattening and contouring of components.

Tooling and Equipment Comparison

Edge milling uses single-point or multi-point cutting tools designed for smaller, more precise cuts along the workpiece edge, while face milling employs larger, multi-tooth cutters for broader surface removal and higher material removal rates. Your choice between edge and face milling depends on tooling size, machine power, and the complexity of the workpiece, with face milling typically requiring robust machines and heavy-duty cutters. In terms of equipment, face milling needs higher-speed spindles and larger tool holders, whereas edge milling tools are compatible with lighter, more versatile setups suitable for detailed finishing.

Material Removal Rate Analysis

Edge milling typically achieves a higher Material Removal Rate (MRR) on narrow surfaces due to the engagement of the cutting edge with the workpiece, optimizing chip thickness and cutting speed. Face milling excels in removing large volumes of material from flat surfaces because multiple teeth of the cutter engage simultaneously, distributing cutting forces and enhancing efficiency. Comparing both, face milling generally offers superior MRR for bulk material removal, while edge milling is better suited for precision and complex contour machining requiring lower MRR.

Surface Finish and Accuracy

Edge milling offers superior surface finish and higher accuracy on narrow or detailed features due to the smaller cutting diameter and focused tool engagement. Face milling produces flatter surfaces over larger areas but may sacrifice fine details and precision compared to edge milling. The choice depends on the specific machining requirements, with edge milling excelling in precision and surface quality on intricate edges.

Cost Efficiency and Productivity

Edge milling typically offers higher cost efficiency for smaller, detailed cuts due to lower tool wear and quicker setup times, while face milling excels in productivity for large, flat surfaces by removing more material per pass. Your machining choice should consider the specific job size, complexity, and desired finish quality to maximize output and minimize expenses. Optimizing between edge and face milling can significantly impact operational efficiency and reduce overall manufacturing costs.

Common Challenges and Solutions

Edge milling often faces challenges with tool deflection and poor surface finish, which can be mitigated by using rigid tool holders and optimizing feed rates. Face milling encounters difficulties such as uneven tool wear and vibration, addressed effectively through balanced cutters and selecting appropriate spindle speeds. Both processes benefit from precise coolant application and routine tool maintenance to enhance machining accuracy and extend tool life.

Choosing the Appropriate Milling Technique

Selecting between edge milling and face milling depends primarily on the desired surface finish and material removal rate. Edge milling excels in creating slots, grooves, and intricate contours with high precision using the cutter's periphery, while face milling offers superior flat surface quality and faster material removal on workpieces with large horizontal surfaces. Milling operations on materials like steel, aluminum, or cast iron benefit from choosing the technique that optimizes cutting force, tool life, and surface integrity specific to their application needs.

Edge Milling vs Face Milling Infographic

libmatt.com

libmatt.com