Flux Cored Arc Welding (FCAW) uses a tubular wire filled with flux that generates shielding gas when heated, allowing welding in outdoor or windy conditions without external gas. Gas Metal Arc Welding (GMAW), also known as MIG welding, relies on an external shielding gas to protect the weld pool, providing cleaner welds ideal for thinner materials and indoor use.

Table of Comparison

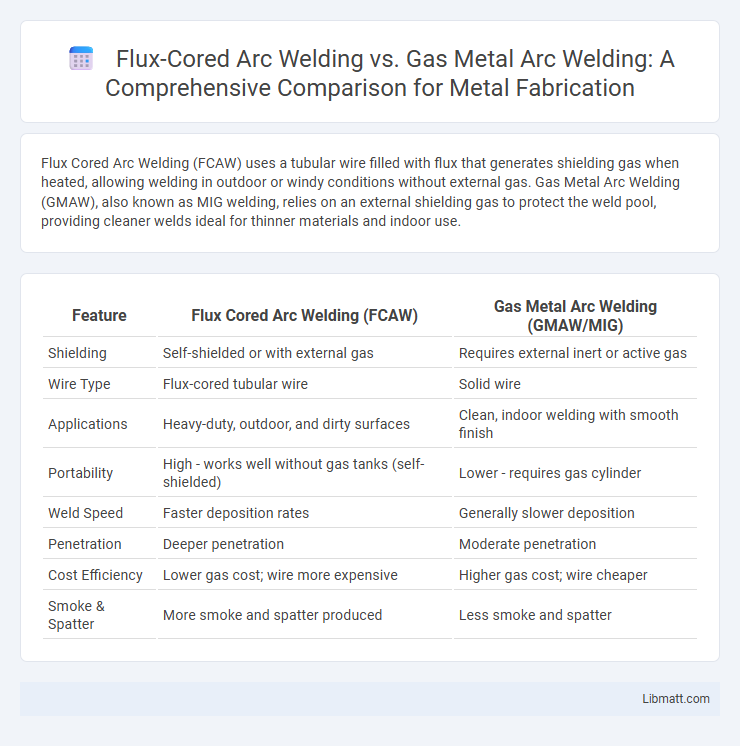

| Feature | Flux Cored Arc Welding (FCAW) | Gas Metal Arc Welding (GMAW/MIG) |

|---|---|---|

| Shielding | Self-shielded or with external gas | Requires external inert or active gas |

| Wire Type | Flux-cored tubular wire | Solid wire |

| Applications | Heavy-duty, outdoor, and dirty surfaces | Clean, indoor welding with smooth finish |

| Portability | High - works well without gas tanks (self-shielded) | Lower - requires gas cylinder |

| Weld Speed | Faster deposition rates | Generally slower deposition |

| Penetration | Deeper penetration | Moderate penetration |

| Cost Efficiency | Lower gas cost; wire more expensive | Higher gas cost; wire cheaper |

| Smoke & Spatter | More smoke and spatter produced | Less smoke and spatter |

Introduction to Flux Cored Arc Welding and Gas Metal Arc Welding

Flux Cored Arc Welding (FCAW) uses a tubular wire filled with flux to create a protective shielding gas during welding, making it ideal for outdoor and heavy-duty applications. Gas Metal Arc Welding (GMAW), commonly known as MIG welding, employs a solid wire electrode and an external shielding gas, offering high welding speed and clean welds in controlled environments. Understanding your project's environmental conditions and material requirements will help determine whether FCAW or GMAW is the more efficient and effective welding method.

Fundamental Principles of FCAW and GMAW

Flux Cored Arc Welding (FCAW) uses a tubular wire filled with flux that generates shielding gas and slag to protect the weld pool, enabling welding in various positions and environments without external gas in self-shielded modes. Gas Metal Arc Welding (GMAW) employs a solid wire electrode and an external shielding gas, such as argon or CO2, to shield the weld area from atmospheric contamination, resulting in cleaner welds ideal for thin materials and automated processes. Understanding these fundamental principles helps you select the appropriate welding method based on factors like material type, welding position, and environmental conditions.

Equipment and Consumables Comparison

Flux Cored Arc Welding (FCAW) uses tubular wire filled with flux, eliminating the need for an external shielding gas, while Gas Metal Arc Welding (GMAW) relies on a solid wire electrode and requires a constant flow of shielding gas like argon or CO2. FCAW equipment tends to be more portable and cost-effective due to the absence of gas cylinders, but the consumables can be pricier and generate more slag that requires post-weld cleanup. Your choice between FCAW and GMAW should consider equipment portability, consumable cost, and the cleanliness of the finished weld based on project requirements.

Welding Process Differences

Flux Cored Arc Welding (FCAW) uses a tubular wire filled with flux, enabling welding without external shielding gas, ideal for outdoor or windy conditions. Gas Metal Arc Welding (GMAW) utilizes a solid wire with an external shielding gas, providing cleaner welds and better control in indoor environments. Your choice depends on the welding environment and material requirements, balancing flux benefits against gas shielding precision.

Metal Deposition Rates and Productivity

Flux Cored Arc Welding (FCAW) offers higher metal deposition rates compared to Gas Metal Arc Welding (GMAW), resulting in increased productivity for thick materials and heavy-duty applications. FCAW's self-shielding flux enables continuous welding without the need for external shielding gas, reducing downtime and enhancing job site versatility. GMAW, while providing cleaner welds with less slag, typically operates at lower deposition rates, making it more suitable for thinner materials and precision welding tasks.

Shielding Methods and Their Impacts

Flux Cored Arc Welding (FCAW) uses a tubular wire filled with flux that generates its own shielding gas, providing protection against atmospheric contamination and allowing for effective welding outdoors or in windy conditions. Gas Metal Arc Welding (GMAW) relies on an external inert or semi-inert gas supply, such as argon or CO2, to shield the weld pool, resulting in cleaner welds but requiring equipment to maintain constant gas flow. Understanding these shielding methods helps you choose the appropriate welding process based on environmental conditions and desired weld quality.

Suitability for Various Materials and Thicknesses

Flux Cored Arc Welding (FCAW) excels in welding thicker materials and is highly effective on dirty or rusty metals, making it suitable for heavy-duty construction steels and thicker plates. Gas Metal Arc Welding (GMAW), also known as MIG welding, provides superior control and cleaner welds ideal for thinner materials and non-ferrous metals like aluminum and stainless steel. FCAW's flux core enables deeper penetration on thicker sections, while GMAW's shielding gas ensures a stable arc and high-quality welds on precision applications with varying metal thicknesses.

Weld Quality and Appearance

Flux Cored Arc Welding (FCAW) typically produces robust welds with excellent penetration, making it ideal for thicker materials and outdoor applications, though it can result in slightly rougher bead appearance due to slag. Gas Metal Arc Welding (GMAW) offers cleaner, more aesthetically pleasing welds with minimal spatter, favored for projects requiring smooth, uniform finishes. Both methods maintain high weld quality, but GMAW excels in visual appeal while FCAW delivers greater adaptability in challenging environments.

Typical Applications and Industry Uses

Flux Cored Arc Welding (FCAW) is commonly used in heavy construction, shipbuilding, and industrial fabrication due to its excellent performance on thick materials and in outdoor environments. Gas Metal Arc Welding (GMAW), also known as MIG welding, is preferred in automotive manufacturing, aerospace, and precision metalworking for its clean welds and suitability on thin to medium gauge metals. Both methods are vital in manufacturing and repair sectors, but FCAW excels in high-deposition productivity while GMAW offers superior weld quality and speed on controlled surfaces.

Cost Considerations and Economic Analysis

Flux Cored Arc Welding (FCAW) generally incurs higher consumable costs due to the specialized flux-cored wire, but it reduces overall expenses by eliminating the need for an external shielding gas, making it economically advantageous in outdoor or drafty environments. Gas Metal Arc Welding (GMAW) requires continuous shielding gas supply, increasing operational costs, especially in large-scale or prolonged welds, yet offers faster deposition rates and cleaner welds that can reduce post-weld processing expenses. An economic analysis reveals that FCAW is cost-effective for heavy fabrication and fieldwork, while GMAW provides better cost efficiency in controlled, indoor manufacturing settings where shielding gas management is feasible.

Flux Cored Arc Welding vs Gas Metal Arc Welding Infographic

libmatt.com

libmatt.com