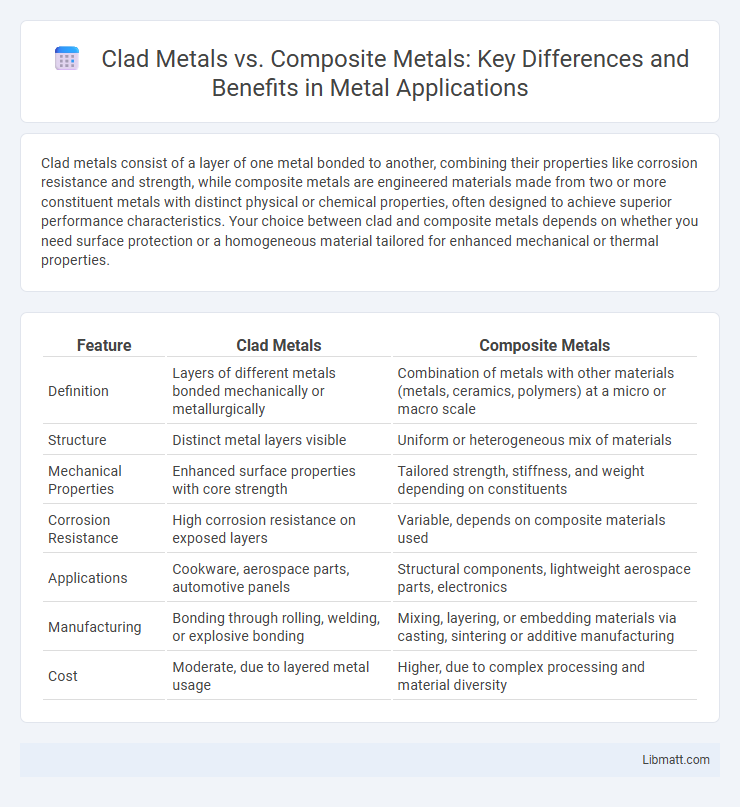

Clad metals consist of a layer of one metal bonded to another, combining their properties like corrosion resistance and strength, while composite metals are engineered materials made from two or more constituent metals with distinct physical or chemical properties, often designed to achieve superior performance characteristics. Your choice between clad and composite metals depends on whether you need surface protection or a homogeneous material tailored for enhanced mechanical or thermal properties.

Table of Comparison

| Feature | Clad Metals | Composite Metals |

|---|---|---|

| Definition | Layers of different metals bonded mechanically or metallurgically | Combination of metals with other materials (metals, ceramics, polymers) at a micro or macro scale |

| Structure | Distinct metal layers visible | Uniform or heterogeneous mix of materials |

| Mechanical Properties | Enhanced surface properties with core strength | Tailored strength, stiffness, and weight depending on constituents |

| Corrosion Resistance | High corrosion resistance on exposed layers | Variable, depends on composite materials used |

| Applications | Cookware, aerospace parts, automotive panels | Structural components, lightweight aerospace parts, electronics |

| Manufacturing | Bonding through rolling, welding, or explosive bonding | Mixing, layering, or embedding materials via casting, sintering or additive manufacturing |

| Cost | Moderate, due to layered metal usage | Higher, due to complex processing and material diversity |

Introduction to Clad Metals and Composite Metals

Clad metals consist of a core metal bonded to one or more layers of different metals to enhance properties such as corrosion resistance and strength. Composite metals combine two or more distinct materials, often metal with non-metal components, to achieve superior mechanical performance and durability. Understanding these materials helps you select the right solution for applications requiring specific structural or environmental advantages.

Definitions: What Are Clad Metals?

Clad metals consist of two or more bonded layers of different metals, combining the advantageous properties of each, such as corrosion resistance and high strength. Unlike composite metals, which typically involve a matrix embedded with reinforcing materials, clad metals maintain distinct metal layers fused through processes like rolling or explosive bonding. This layered structure enhances performance in applications requiring both durability and specialized surface characteristics.

Definitions: What Are Composite Metals?

Composite metals are engineered materials composed of two or more distinct metal or metallic phases combined to enhance mechanical properties such as strength, stiffness, and corrosion resistance. These metals often include a metal matrix reinforced by fibers, particles, or other metals, creating a synergistic effect that surpasses the capabilities of individual metal components. Unlike clad metals that consist of bonded layers of different metals, composite metals exhibit a more integrated microstructure with improved performance tailored for specific industrial applications.

Manufacturing Processes: Clad vs Composite Metals

Clad metals are produced by bonding dissimilar metal layers through processes such as roll bonding, explosion welding, or diffusion bonding, ensuring a metallurgical bond with distinct layers visible. Composite metals are made by embedding reinforcing materials like fibers or particles within a metal matrix via techniques including powder metallurgy, casting, or additive manufacturing, resulting in a uniform material with enhanced mechanical properties. The manufacturing of clad metals emphasizes interlayer adhesion and layer integrity, whereas composite metals focus on achieving homogeneous dispersion and strong interfacial bonding between the matrix and reinforcement.

Key Material Properties Comparison

Clad metals combine layers of different metals to enhance corrosion resistance, strength, and thermal conductivity, offering superior durability compared to composite metals, which blend metal matrices with non-metal reinforcements to achieve improved wear resistance and reduced weight. Clad metals maintain the distinct physical and mechanical properties of each layer, providing targeted performance benefits, while composite metals exhibit homogeneous material properties optimized for specific applications like aerospace and automotive industries. The choice between clad and composite metals depends on required factors such as tensile strength, fatigue resistance, thermal stability, and cost-effectiveness for the intended engineering use.

Common Applications of Clad Metals

Clad metals are widely used in applications requiring corrosion resistance alongside structural strength, such as in chemical processing equipment, heat exchangers, and aerospace components. Their unique layering allows for superior durability in harsh environments while maintaining cost-effectiveness by using a less expensive core metal. You can find clad metals in architectural facades and electrical contacts, where both conductivity and protection are essential.

Common Applications of Composite Metals

Composite metals are widely used in aerospace for their high strength-to-weight ratio, enhancing fuel efficiency and structural performance. In automotive industries, they improve crash resistance and reduce vehicle weight, contributing to better fuel economy and emissions standards. These materials also find applications in construction and sporting goods, offering durability and corrosion resistance while maintaining flexibility and lightweight properties.

Advantages and Limitations of Clad Metals

Clad metals offer superior corrosion resistance and enhanced mechanical properties by combining the strengths of different metals, making them ideal for harsh environments and structural applications. They provide cost-effective solutions by utilizing a thin layer of expensive metal bonded to a less expensive substrate, which reduces material costs without sacrificing performance. Limitations include potential delamination under extreme stress or thermal cycling, and challenges in repair or reprocessing compared to composite metals with engineered interfaces.

Advantages and Limitations of Composite Metals

Composite metals offer superior strength-to-weight ratios and enhanced corrosion resistance compared to clad metals, making them ideal for aerospace and automotive applications. Their ability to combine distinct material properties within a single structure provides greater design flexibility and improved fatigue performance. However, composite metals can be more expensive to produce and may present challenges in recyclability and repair compared to traditional clad metals.

Choosing the Right Material: Clad vs Composite Metals

Choosing the right material between clad metals and composite metals depends on your application's specific mechanical, thermal, and corrosion resistance requirements. Clad metals combine layers of different metals bonded together, offering enhanced surface properties while retaining the core metal's strength, whereas composite metals integrate distinct materials at a microscopic level to provide customized mechanical and chemical characteristics. Understanding factors such as weight, cost, and durability will help you select the optimal material for maximum performance and longevity.

clad metals vs composite metals Infographic

libmatt.com

libmatt.com