Tube bending involves shaping hollow structural sections with a consistent outer diameter and wall thickness, commonly used in applications requiring precise bends without deforming the tube's cross-section. Pipe bending focuses on altering pipes, which often have thicker walls and are primarily designed for fluid transport, meaning the bending process must accommodate potential wall thickness variations and internal diameter changes.

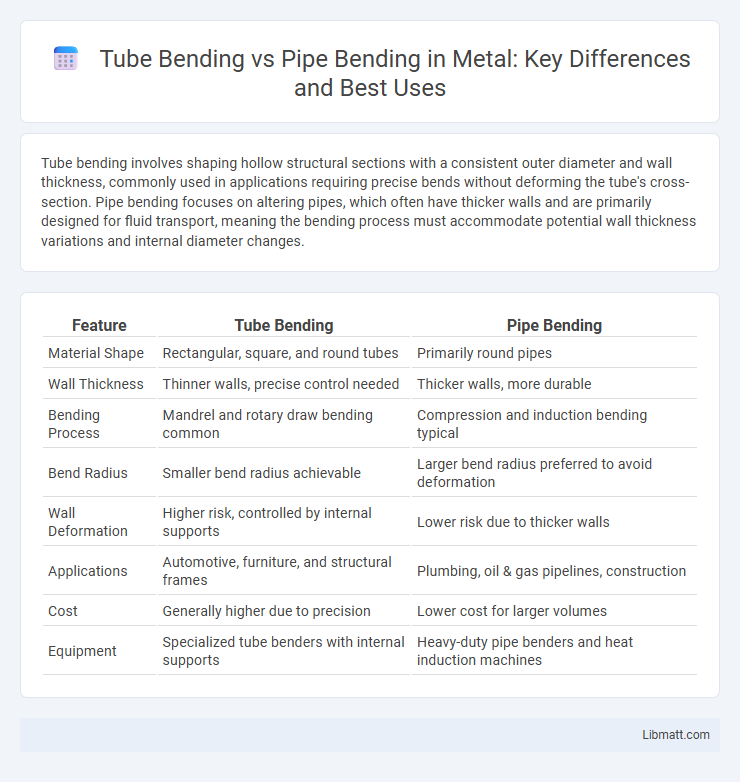

Table of Comparison

| Feature | Tube Bending | Pipe Bending |

|---|---|---|

| Material Shape | Rectangular, square, and round tubes | Primarily round pipes |

| Wall Thickness | Thinner walls, precise control needed | Thicker walls, more durable |

| Bending Process | Mandrel and rotary draw bending common | Compression and induction bending typical |

| Bend Radius | Smaller bend radius achievable | Larger bend radius preferred to avoid deformation |

| Wall Deformation | Higher risk, controlled by internal supports | Lower risk due to thicker walls |

| Applications | Automotive, furniture, and structural frames | Plumbing, oil & gas pipelines, construction |

| Cost | Generally higher due to precision | Lower cost for larger volumes |

| Equipment | Specialized tube benders with internal supports | Heavy-duty pipe benders and heat induction machines |

Introduction to Tube Bending vs Pipe Bending

Tube bending involves shaping hollow, thin-walled tubes with precise tolerances commonly used in automotive, aerospace, and furniture industries. Pipe bending handles thicker-walled pipes designed for fluid transport in plumbing, oil and gas, and industrial applications, emphasizing strength and flow integrity. Both processes require specialized machinery, but tube bending prioritizes maintaining cross-sectional shape while pipe bending focuses on structural stability.

Defining Tubes and Pipes: Key Differences

Tubes and pipes differ primarily in their specifications and applications, with tubes defined by precise outer diameter and wall thickness for structural or mechanical purposes, while pipes are measured by nominal pipe size (NPS) and used mainly for fluid transport. Tube bending requires exact tolerances to maintain integrity and fit in engineering projects, whereas pipe bending focuses on accommodating fluid flow with less stringent dimensional precision. Knowing these distinctions helps you select the appropriate bending technique based on whether your project demands exact dimensions or efficient fluid conveyance.

Common Applications: Tube Bending vs Pipe Bending

Tube bending is commonly used in automotive frames, aircraft components, and furniture manufacturing where precise shapes and smooth finishes are essential. Pipe bending finds frequent applications in plumbing, oil and gas pipelines, and HVAC systems due to its ability to handle larger diameters and higher pressure requirements. The choice between tube and pipe bending depends on the application's structural demands and fluid flow characteristics.

Material Considerations for Bending

Material considerations for tube bending and pipe bending differ significantly due to the variations in wall thickness and cross-sectional shape. Tubes, typically having thinner walls and square or rectangular cross-sections, require careful attention to avoid deformation such as wrinkling or collapse during bending, often demanding materials with higher ductility like aluminum or mild steel. Pipes, featuring thicker walls and round sections, offer greater resistance to deformation, allowing materials such as stainless steel or carbon steel to be bent with less risk of structural compromise, but necessitate precise control of bend radius to maintain integrity.

Popular Bending Methods for Tubes and Pipes

Popular bending methods for tubes and pipes include rotary draw bending, mandrel bending, compression bending, and roll bending. Rotary draw bending provides precise, tight-radius bends ideal for tubes, while mandrel bending supports the pipe's interior to prevent collapse during complex bends. Compression bending and roll bending are commonly used for large-radius bends in pipes, accommodating a variety of materials and thicknesses to ensure your project meets specific structural requirements.

Equipment Used in Tube and Pipe Bending

Tube bending typically requires rotary draw benders or mandrel benders designed for precise control and smooth curvature, while pipe bending often uses compression or induction bending machines suited for larger diameters and thicker walls. The equipment choice depends on your project's material dimensions, as tube benders handle smaller, thinner-walled sections and pipe benders accommodate heavier, more robust structures. Proper selection ensures accurate bends, maintains structural integrity, and meets specific application requirements.

Precision and Tolerances: Tube vs Pipe Bending

Tube bending offers higher precision and tighter tolerances compared to pipe bending due to its uniform wall thickness and consistent cross-section. Pipes, with varying wall thickness and larger diameters, tend to have less precise bends and greater dimensional deviations. Advanced tube bending machines and CNC technology enable more accurate angle control and consistent bend radii, crucial for applications requiring exact specifications.

Cost Factors and Efficiency Comparison

Tube bending generally incurs higher costs due to its precision requirements and the need for specialized tooling, whereas pipe bending is more cost-effective for simpler, large-diameter bends. Efficiency in tube bending excels for intricate shapes and tight radii, optimizing material usage and reducing waste, while pipe bending offers faster processing times for straightforward bends in construction or plumbing applications. Your choice impacts budget and workflow, balancing precision demands with overall project efficiency.

Common Challenges in Tube and Pipe Bending

Common challenges in tube and pipe bending include maintaining precise dimensional tolerances and preventing material deformation such as wrinkling, ovality, or wall thinning. Differences in tube bending and pipe bending center around cross-sectional shapes, where tube bending typically involves square or rectangular profiles requiring careful control of internal mandrels to avoid collapse. Accurate tool selection and process parameters are essential to minimize springback and ensure the structural integrity of both tubes and pipes across diverse industrial applications.

Choosing the Right Method for Your Project

Tube bending offers precise control with minimal deformation, ideal for projects requiring tight radii and intricate shapes, while pipe bending is better suited for larger diameter applications with thicker walls where structural integrity is critical. Your choice should consider material thickness, bend radius, and application requirements to ensure accurate, durable results. Understanding the mechanical properties and end-use will guide you to select the most efficient bending method for your project.

tube bending vs pipe bending Infographic

libmatt.com

libmatt.com