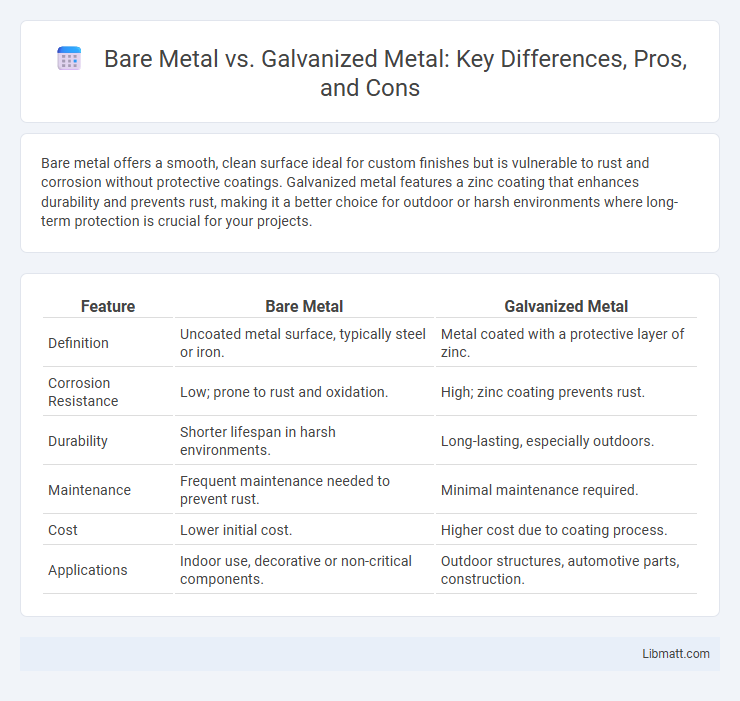

Bare metal offers a smooth, clean surface ideal for custom finishes but is vulnerable to rust and corrosion without protective coatings. Galvanized metal features a zinc coating that enhances durability and prevents rust, making it a better choice for outdoor or harsh environments where long-term protection is crucial for your projects.

Table of Comparison

| Feature | Bare Metal | Galvanized Metal |

|---|---|---|

| Definition | Uncoated metal surface, typically steel or iron. | Metal coated with a protective layer of zinc. |

| Corrosion Resistance | Low; prone to rust and oxidation. | High; zinc coating prevents rust. |

| Durability | Shorter lifespan in harsh environments. | Long-lasting, especially outdoors. |

| Maintenance | Frequent maintenance needed to prevent rust. | Minimal maintenance required. |

| Cost | Lower initial cost. | Higher cost due to coating process. |

| Applications | Indoor use, decorative or non-critical components. | Outdoor structures, automotive parts, construction. |

Introduction to Bare Metal and Galvanized Materials

Bare metal refers to untreated steel or iron that has not undergone any protective coating process, exposing it directly to environmental factors such as moisture and air. Galvanized materials, on the other hand, involve a layer of zinc coating applied through hot-dip or electro-galvanizing methods to prevent rust and corrosion. The choice between bare metal and galvanized depends on the required durability, environmental exposure, and cost considerations for construction or manufacturing projects.

What is Bare Metal?

Bare metal refers to untreated, uncoated metal in its raw state, offering a smooth surface free from paint, galvanization, or other protective layers. This type of metal provides excellent opportunities for custom finishing and coating, allowing Your project to have tailored corrosion resistance or aesthetic appeal. However, bare metal is more susceptible to rust and requires proper handling or treatment to maintain its integrity over time.

What is Galvanized Metal?

Galvanized metal refers to steel or iron that has been coated with a protective layer of zinc to prevent rust and corrosion. This zinc coating forms a barrier that protects the underlying metal from moisture and environmental damage, significantly extending its lifespan compared to bare metal. Commonly used in construction, automotive, and outdoor applications, galvanized metal offers enhanced durability and low maintenance requirements.

Differences in Composition and Manufacturing

Bare metal refers to steel or iron in its untreated state, lacking any protective coatings and composed primarily of pure iron with trace elements. Galvanized metal is steel that has undergone a hot-dip or electro-galvanizing process, where a zinc coating is applied to enhance corrosion resistance by creating a protective barrier. The manufacturing difference lies in the galvanization process, which involves immersing the bare metal into molten zinc or electroplating it, significantly extending the metal's lifespan in harsh environments.

Durability and Corrosion Resistance Comparison

Bare metal typically exhibits lower corrosion resistance due to its unprotected surface, making it prone to rust and degradation in harsh environments. Galvanized metal is coated with a layer of zinc, providing superior corrosion protection and significantly enhancing durability by preventing rust formation over extended periods. The zinc coating acts as a sacrificial barrier, making galvanized metal ideal for outdoor use and applications exposed to moisture or corrosive elements.

Cost Analysis: Bare Metal vs Galvanized

Bare metal steel typically incurs lower upfront costs compared to galvanized steel, making it a budget-friendly option for projects with tight financial constraints. However, your overall expenses may rise due to bare metal's susceptibility to rust and corrosion, leading to increased maintenance or replacement costs over time. Galvanized steel's coating provides long-term protection, reducing lifetime costs despite its higher initial price.

Common Applications and Uses

Bare metal steel is commonly used in applications requiring strong adhesion and weldability, such as automotive body panels, construction frameworks, and heavy machinery. Galvanized steel, coated with a protective layer of zinc, is ideal for outdoor and corrosive environments like roofing, fencing, and marine structures due to its enhanced rust resistance. You should choose bare metal when ease of fabrication is critical, while galvanized steel suits projects demanding long-term durability against moisture and oxidation.

Maintenance Requirements and Longevity

Bare metal surfaces demand frequent maintenance to prevent oxidation and corrosion, requiring regular cleaning and protective coatings to enhance durability. Galvanized steel offers superior corrosion resistance with its zinc coating, significantly reducing maintenance frequency and extending structural lifespan. The longevity of galvanized materials often surpasses bare metal by decades, making it a cost-effective choice for long-term applications exposed to harsh environments.

Environmental Impact and Sustainability

Bare metal surfaces avoid the use of additional coatings, reducing chemical runoff and simplifying recycling processes, which benefits environmental sustainability. Galvanized steel, coated with zinc, provides long-lasting corrosion resistance, extending material lifespan and decreasing the frequency of replacements, thus lowering resource consumption. However, zinc production and galvanizing processes involve energy-intensive steps and emissions, making bare metal recycling generally more eco-friendly when maintained properly.

Choosing the Right Material for Your Project

Choosing the right material for your project depends on factors like durability, cost, and environmental exposure. Bare metal offers a clean surface ideal for painting or coating but requires regular maintenance to prevent rust. Galvanized steel provides a protective zinc coating that enhances corrosion resistance, making it suitable for outdoor or humid conditions where long-term durability is essential.

Bare metal vs galvanized Infographic

libmatt.com

libmatt.com