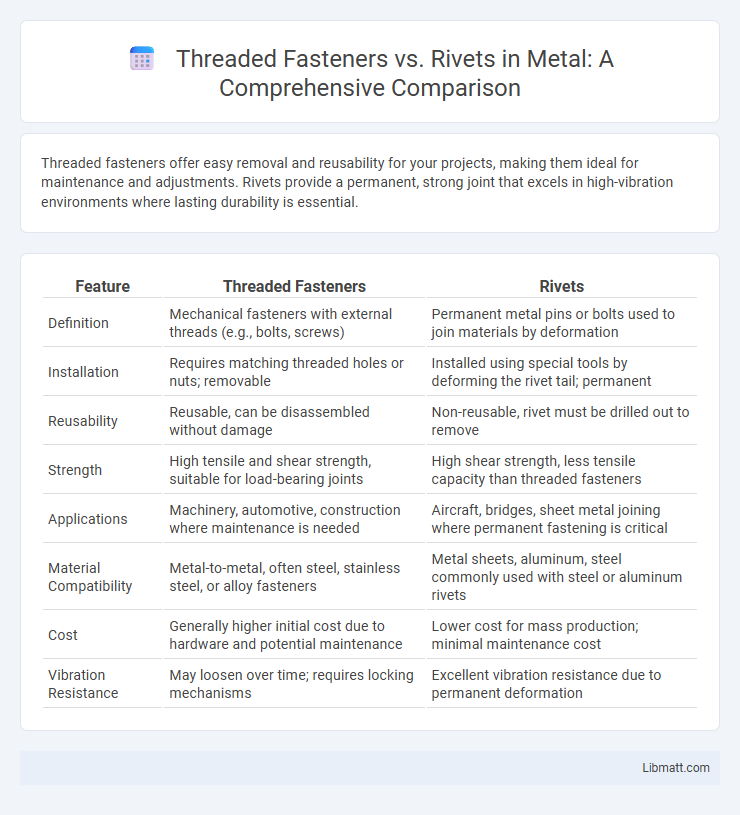

Threaded fasteners offer easy removal and reusability for your projects, making them ideal for maintenance and adjustments. Rivets provide a permanent, strong joint that excels in high-vibration environments where lasting durability is essential.

Table of Comparison

| Feature | Threaded Fasteners | Rivets |

|---|---|---|

| Definition | Mechanical fasteners with external threads (e.g., bolts, screws) | Permanent metal pins or bolts used to join materials by deformation |

| Installation | Requires matching threaded holes or nuts; removable | Installed using special tools by deforming the rivet tail; permanent |

| Reusability | Reusable, can be disassembled without damage | Non-reusable, rivet must be drilled out to remove |

| Strength | High tensile and shear strength, suitable for load-bearing joints | High shear strength, less tensile capacity than threaded fasteners |

| Applications | Machinery, automotive, construction where maintenance is needed | Aircraft, bridges, sheet metal joining where permanent fastening is critical |

| Material Compatibility | Metal-to-metal, often steel, stainless steel, or alloy fasteners | Metal sheets, aluminum, steel commonly used with steel or aluminum rivets |

| Cost | Generally higher initial cost due to hardware and potential maintenance | Lower cost for mass production; minimal maintenance cost |

| Vibration Resistance | May loosen over time; requires locking mechanisms | Excellent vibration resistance due to permanent deformation |

Introduction to Threaded Fasteners and Rivets

Threaded fasteners, including bolts, screws, and nuts, provide strong, adjustable, and reusable connections by engaging with internal or external threads to clamp components securely. Rivets offer permanent fastening solutions by deforming a metal pin through joined materials, creating a high-strength, vibration-resistant joint ideal for aerospace and structural applications. Choosing between threaded fasteners and rivets depends on factors such as load requirements, disassembly needs, and material compatibility.

Definition and Types of Threaded Fasteners

Threaded fasteners are mechanical components designed to join parts by engaging with corresponding internal or external threads, ensuring secure and adjustable connections. Common types include bolts, screws, studs, and nuts, each tailored for specific applications requiring disassembly or repositioning. Understanding these fasteners helps you select the right solution for strength, reliability, and ease of maintenance in your projects.

Overview and Varieties of Rivets

Rivets serve as permanent mechanical fasteners commonly used to join metal sheets and structural components, featuring varieties such as solid, blind, and drive rivets tailored for different applications. Solid rivets require access to both sides of the workpieces and are often employed in aerospace and construction for their high strength and reliability. Blind rivets, also known as pop rivets, allow fastening from one side, making them ideal for maintenance and assembly in confined spaces, while drive rivets are hammered into pre-drilled holes for quick installation in softer materials.

Installation Process Comparison

Threaded fasteners require precise alignment and often the use of nuts, washers, and torque tools during installation, enabling easy disassembly and reassembly for maintenance. Rivets demand permanent installation through deformation, typically involving a rivet gun or hammer, making them ideal for fast, strong, and tamper-resistant joints. Your choice depends on whether you prioritize ease of maintenance with threaded fasteners or the permanence and vibration resistance offered by rivets.

Strength and Load-Bearing Capabilities

Threaded fasteners provide superior strength and load-bearing capabilities due to their ability to be tightened with precise torque, ensuring a secure and adjustable connection. Rivets offer strong shear resistance but lack the tension load capacity and reusability of threaded fasteners, making them ideal for permanent joints with less dynamic load. Your choice depends on whether you require high tensile strength and serviceability, which favors threaded fasteners, or a permanent, vibration-resistant fastening solution suited to rivets.

Application Suitability in Various Industries

Threaded fasteners offer superior versatility for applications requiring frequent assembly and disassembly, making them ideal for automotive, aerospace, and machinery industries. Rivets provide permanent, vibration-resistant joints, preferred in construction, aircraft skins, and shipbuilding where long-lasting, tamper-proof fastening is critical. Selecting between these fasteners depends on maintenance needs, load requirements, and environmental conditions specific to each industry.

Advantages of Threaded Fasteners

Threaded fasteners offer superior strength and ease of removal compared to rivets, making them ideal for applications requiring maintenance or adjustments. These fasteners provide precise torque control, enhancing joint reliability and reducing the risk of loosening under vibration. Your choice of threaded fasteners ensures faster assembly and disassembly, saving time and improving overall efficiency in mechanical connections.

Benefits of Using Rivets

Rivets provide a permanent and reliable fastening solution ideal for applications requiring strong shear strength and vibration resistance. Their ability to join dissimilar materials without the need for pre-tapped holes reduces assembly time and maintenance requirements. Using rivets enhances the durability and integrity of your structures, especially in aerospace and automotive industries.

Cost Analysis: Threaded Fasteners vs Rivets

Threaded fasteners typically incur higher initial costs due to material quality and manufacturing precision, but offer greater reusability and ease of maintenance, which can reduce long-term expenses. Rivets, while generally cheaper upfront and faster to install, require specialized tools and often permanent assembly, leading to higher labor costs during repairs or modifications. Considering lifecycle costs, threaded fasteners provide better economic efficiency in applications demanding frequent disassembly and reassembly, whereas rivets favor cost-effectiveness in permanent, high-volume production settings.

Choosing the Right Fastener for Your Project

Threaded fasteners provide strong, reusable connections ideal for applications requiring regular disassembly or adjustments, such as machinery and automotive assemblies. Rivets offer permanent, vibration-resistant joints perfect for structures exposed to shear forces, including aircraft and bridges. Selecting the right fastener depends on factors like load type, maintenance needs, and material compatibility to ensure optimal performance and durability.

Threaded Fasteners vs Rivets Infographic

libmatt.com

libmatt.com