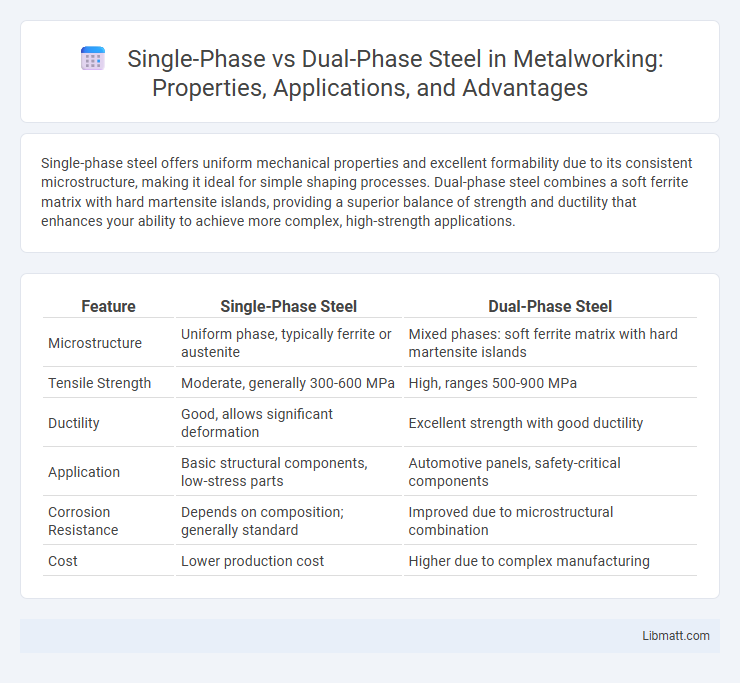

Single-phase steel offers uniform mechanical properties and excellent formability due to its consistent microstructure, making it ideal for simple shaping processes. Dual-phase steel combines a soft ferrite matrix with hard martensite islands, providing a superior balance of strength and ductility that enhances your ability to achieve more complex, high-strength applications.

Table of Comparison

| Feature | Single-Phase Steel | Dual-Phase Steel |

|---|---|---|

| Microstructure | Uniform phase, typically ferrite or austenite | Mixed phases: soft ferrite matrix with hard martensite islands |

| Tensile Strength | Moderate, generally 300-600 MPa | High, ranges 500-900 MPa |

| Ductility | Good, allows significant deformation | Excellent strength with good ductility |

| Application | Basic structural components, low-stress parts | Automotive panels, safety-critical components |

| Corrosion Resistance | Depends on composition; generally standard | Improved due to microstructural combination |

| Cost | Lower production cost | Higher due to complex manufacturing |

Introduction to Single-Phase and Dual-Phase Steels

Single-phase steels consist primarily of one microstructural phase, typically ferrite or austenite, which offers uniform mechanical properties suitable for general applications. Dual-phase steels feature a microstructure composed of a soft ferrite matrix with dispersed hard martensite, providing a superior balance of strength and ductility. The dual-phase configuration enhances formability and impact resistance, making it ideal for automotive and structural uses where lightweight strength is critical.

Microstructural Differences Between Single-Phase and Dual-Phase Steels

Single-phase steels consist of a uniform microstructure, typically ferrite, which provides good ductility and forming capabilities. Dual-phase steels contain a mixture of soft ferrite and hard martensite phases, resulting in improved strength and strain-hardening properties. Understanding these microstructural differences helps optimize Your material choice for applications requiring a balance between strength and ductility.

Chemical Composition and Alloying Elements

Single-phase steel primarily consists of a uniform microstructure such as ferrite or austenite, with a simplified chemical composition typically dominated by iron, carbon (usually less than 0.25%), and minimal alloying elements like manganese and silicon to enhance strength and ductility. Dual-phase steel contains a microstructure combining soft ferrite and hard martensite phases, achieved through specific heat treatments and alloying with elements like carbon (higher than in single-phase), manganese, and small amounts of silicon and chromium to refine phases and improve mechanical properties. The precise control of carbon and alloying element concentrations in dual-phase steel optimizes phase distribution for enhanced strength and formability compared to the more homogeneous single-phase steels.

Mechanical Properties Comparison

Single-phase steel, typically consisting of a uniform microstructure such as ferrite or martensite, offers moderate strength and good ductility, making it suitable for applications requiring ease of forming and moderate load-bearing capacity. Dual-phase steel combines soft ferrite and hard martensite phases, resulting in a superior balance of high tensile strength and excellent ductility, which enhances crashworthiness and energy absorption in automotive components. The dual-phase microstructure provides improved yield strength and strain hardening capability compared to single-phase steels, leading to better performance in structural applications demanding both strength and formability.

Formability and Workability

Single-phase steel offers superior formability due to its uniform microstructure, allowing easier shaping and bending without cracking. Dual-phase steel, featuring a mix of soft ferrite and hard martensite, provides enhanced workability with higher strength and better strain hardening, enabling complex forming processes while maintaining durability. Understanding these differences helps optimize material selection for Your manufacturing requirements, balancing ease of shaping against strength.

Strength and Ductility Balance

Single-phase steel offers good ductility but generally lower strength, making it suitable for applications requiring extensive forming. Dual-phase steel provides an excellent balance of high strength and improved ductility due to its microstructure of martensite dispersed in a ferrite matrix. Your choice between these steels depends on the specific strength and ductility requirements for optimal performance in automotive or structural applications.

Welding and Fabrication Considerations

Single-phase steel offers uniform microstructure, simplifying welding processes with reduced risk of cracking and distortion, making it ideal for straightforward fabrication. Dual-phase steel, with its combination of soft ferrite and hard martensite phases, requires precise control of welding parameters to prevent phase transformation issues and maintain mechanical properties. Your choice between single-phase and dual-phase steel directly impacts fabrication strategies, as dual-phase demands advanced welding techniques to preserve strength and ductility.

Applications in the Automotive and Construction Industries

Single-phase steel, known for its uniform microstructure, is widely used in automotive body panels and structural components due to its good formability and corrosion resistance. Dual-phase steel, featuring a microstructure of ferrite and martensite, offers superior strength and ductility, making it ideal for automotive safety parts like crash-resistant beams and reinforcements. In construction, single-phase steel suits general structural frameworks, whereas dual-phase steel is preferred for applications requiring enhanced load-bearing capacity and toughness, such as high-strength reinforcement bars and heavy-duty structural supports.

Cost Implications and Material Availability

Single-phase steels generally have lower cost implications due to simpler manufacturing processes and more abundant raw materials, making them widely available for standard applications. Dual-phase steels, while offering superior strength and ductility, typically incur higher production costs because of complex heat treatments and alloying elements, which may affect material availability. Your choice between single-phase and dual-phase steel should consider budget constraints and supply chain reliability based on project requirements.

Future Trends in Steel Development

Future trends in steel development emphasize the advancement of single-phase steel for improved corrosion resistance and weldability, while dual-phase steel continues to evolve with enhanced strength-to-weight ratios for automotive applications. Innovations in microstructure engineering aim to optimize mechanical properties, enabling your products to meet stricter environmental regulations and fuel efficiency standards. Researchers focus on combining nano-scale phase distributions and alloying techniques to push the boundaries of performance in both single-phase and dual-phase steel grades.

Single-phase vs dual-phase steel Infographic

libmatt.com

libmatt.com