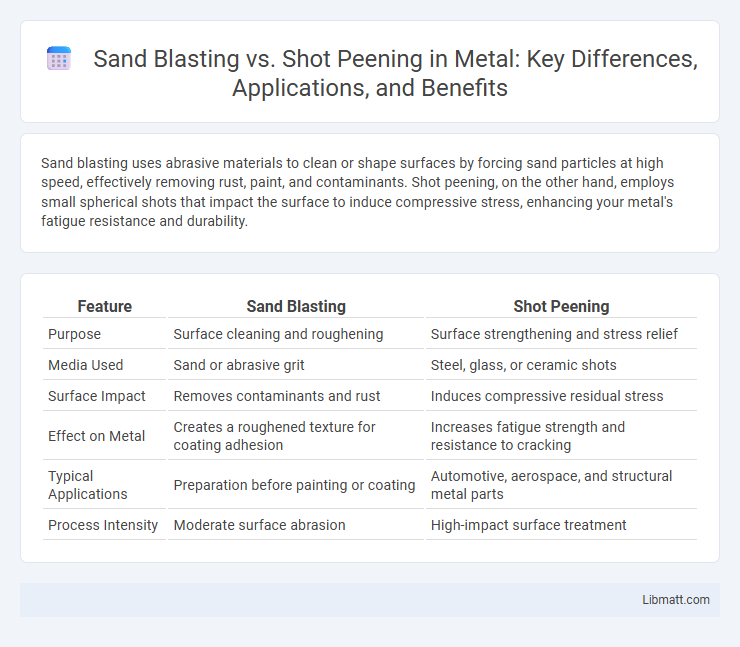

Sand blasting uses abrasive materials to clean or shape surfaces by forcing sand particles at high speed, effectively removing rust, paint, and contaminants. Shot peening, on the other hand, employs small spherical shots that impact the surface to induce compressive stress, enhancing your metal's fatigue resistance and durability.

Table of Comparison

| Feature | Sand Blasting | Shot Peening |

|---|---|---|

| Purpose | Surface cleaning and roughening | Surface strengthening and stress relief |

| Media Used | Sand or abrasive grit | Steel, glass, or ceramic shots |

| Surface Impact | Removes contaminants and rust | Induces compressive residual stress |

| Effect on Metal | Creates a roughened texture for coating adhesion | Increases fatigue strength and resistance to cracking |

| Typical Applications | Preparation before painting or coating | Automotive, aerospace, and structural metal parts |

| Process Intensity | Moderate surface abrasion | High-impact surface treatment |

Introduction to Surface Treatment Methods

Surface treatment methods like sand blasting and shot peening enhance metal durability and performance by modifying surface properties. Sand blasting uses high-pressure abrasive particles to clean and roughen surfaces, improving paint adhesion and removing contaminants. Shot peening employs small spherical media to induce compressive stresses, increasing fatigue strength and resistance to stress corrosion cracking.

What is Sand Blasting?

Sand blasting is a surface treatment technique that uses high-pressure air to propel abrasive particles, typically sand, to clean, smooth, or shape a material's surface. This process effectively removes rust, paint, or contaminants, improving surface texture and preparing it for further coating or finishing. Frequently used in industrial maintenance and manufacturing, sand blasting enhances adhesion properties and surface durability.

What is Shot Peening?

Shot peening is a metal surface treatment process where small spherical media, typically steel, glass, or ceramic shots, are blasted onto the surface to induce compressive stress. This technique enhances material fatigue strength, reduces surface cracks, and improves resistance to stress corrosion cracking. Unlike sand blasting, which primarily cleans or roughens surfaces, shot peening specifically strengthens metal components used in aerospace, automotive, and manufacturing industries.

Key Differences Between Sand Blasting and Shot Peening

Sand blasting uses abrasive particles like sand to clean or texture surfaces by forcibly propelling them, primarily focusing on surface preparation and paint removal. Shot peening employs small spherical media, such as steel or ceramic balls, to induce compressive stress on metal surfaces, significantly enhancing fatigue resistance and durability. The key difference lies in sand blasting's abrasive cleaning action versus shot peening's surface strengthening through controlled plastic deformation.

Applications of Sand Blasting

Sand blasting is extensively applied in surface preparation for painting, coating, and cleaning metal parts, automotive bodies, and industrial equipment by removing rust, scale, and old paint. It is also utilized in etching glass, cleaning masonry, and preparing surfaces for welding and fabrication processes. This technique enhances adhesion, improves surface texture, and extends the lifespan of materials across various manufacturing, construction, and restoration industries.

Applications of Shot Peening

Shot peening is widely used in aerospace, automotive, and manufacturing industries to improve fatigue strength and resistance to stress corrosion cracking in metal components. This surface treatment method induces compressive residual stresses on parts such as gears, springs, turbine blades, and crankshafts, enhancing their durability and performance under cyclic loading. Its applications extend to enhancing weld fatigue resistance and extending the lifespan of critical structural elements in heavy machinery and transportation equipment.

Effects on Surface Finish and Material Strength

Sand blasting produces a rougher surface finish by aggressively removing contaminants and creating uniform texture, which enhances paint adhesion but may reduce fatigue strength due to surface micro-cracks. Shot peening improves material strength by inducing beneficial compressive residual stresses on the surface, enhancing resistance to fatigue and stress corrosion cracking while maintaining a smoother finish compared to sand blasting. The choice between sand blasting and shot peening depends on the desired balance between surface finish quality and mechanical performance requirements.

Safety Considerations for Each Process

Sand blasting and shot peening require strict safety measures due to the high-velocity particles involved; operators must wear protective gear such as respirators, gloves, and eye protection to prevent inhalation of harmful dust and projectile injuries. Sand blasting generates silica dust, which poses respiratory hazards and necessitates proper ventilation and dust collection systems to protect workers. Shot peening produces less airborne dust but demands careful control of media containment and noise levels to maintain a safe working environment for Your team.

Cost Comparison: Sand Blasting vs Shot Peening

Sand blasting typically incurs lower initial setup costs compared to shot peening, making it a more economical choice for surface cleaning and preparation tasks. Shot peening, although more expensive due to specialized equipment and precision control, offers enhanced durability and stress relief benefits, potentially reducing long-term maintenance expenses. Evaluating total cost-effectiveness depends on the specific application requirements, including material type, finish quality, and component longevity.

Choosing the Right Method for Your Needs

Selecting between sand blasting and shot peening depends on your surface treatment goals and material requirements. Sand blasting effectively cleans and prepares surfaces by removing rust or paint, while shot peening enhances metal fatigue strength through controlled surface deformation. Understanding your project's durability demands and finish quality ensures you choose the right method for optimal performance.

Sand Blasting vs Shot Peening Infographic

libmatt.com

libmatt.com