Batch galvanizing involves dipping steel parts into molten zinc for uniform corrosion resistance, ideal for smaller or complex items requiring thorough coating. Continuous galvanizing is a high-speed process where steel sheets pass through a molten zinc bath, providing efficient, consistent protection suited for large-scale production and your structural applications.

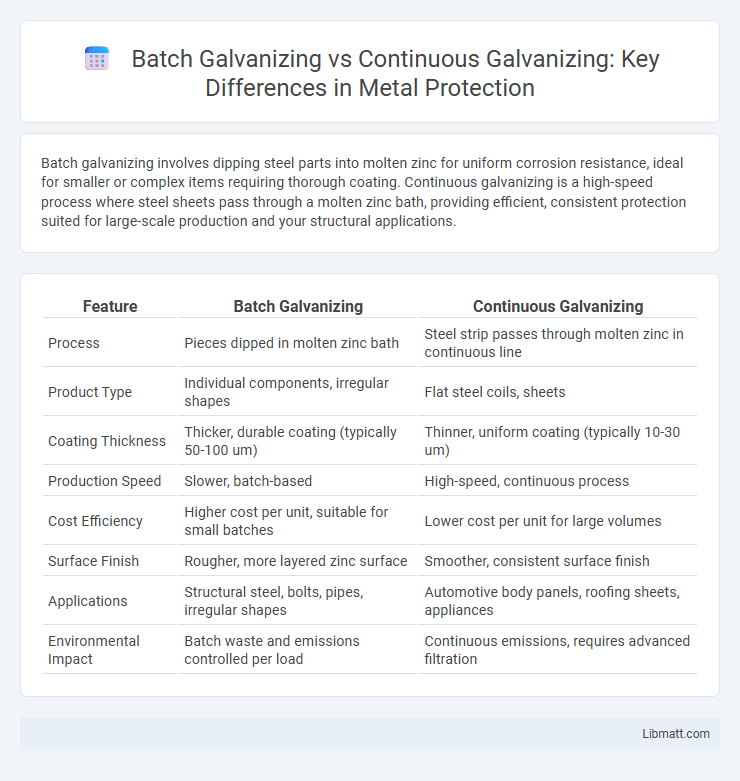

Table of Comparison

| Feature | Batch Galvanizing | Continuous Galvanizing |

|---|---|---|

| Process | Pieces dipped in molten zinc bath | Steel strip passes through molten zinc in continuous line |

| Product Type | Individual components, irregular shapes | Flat steel coils, sheets |

| Coating Thickness | Thicker, durable coating (typically 50-100 um) | Thinner, uniform coating (typically 10-30 um) |

| Production Speed | Slower, batch-based | High-speed, continuous process |

| Cost Efficiency | Higher cost per unit, suitable for small batches | Lower cost per unit for large volumes |

| Surface Finish | Rougher, more layered zinc surface | Smoother, consistent surface finish |

| Applications | Structural steel, bolts, pipes, irregular shapes | Automotive body panels, roofing sheets, appliances |

| Environmental Impact | Batch waste and emissions controlled per load | Continuous emissions, requires advanced filtration |

Introduction to Galvanizing Processes

Batch galvanizing involves immersing individual steel parts into molten zinc, providing uniform coating thickness and excellent corrosion resistance for custom or small production runs. Continuous galvanizing processes steel sheets or coils by passing them through a molten zinc bath, offering high-speed, economical protection ideal for large-scale manufacturing. Your choice depends on production volume and application requirements, with batch suitable for complex shapes and continuous preferred for flat materials.

What is Batch Galvanizing?

Batch galvanizing is a hot-dip process where steel or iron components are dipped into molten zinc in individual batches, ensuring uniform coating thickness and corrosion protection for each item. This method is ideal for smaller, irregularly shaped, or custom-sized parts requiring thorough zinc coverage. Your components receive enhanced durability through this controlled and customizable galvanizing technique.

What is Continuous Galvanizing?

Continuous galvanizing is a process where steel coils are continuously passed through a molten zinc bath to create a uniform, corrosion-resistant coating. This method is highly efficient for high-volume production and provides consistent coating thickness and surface quality. It is widely used in automotive, construction, and appliance industries for its speed and ability to produce long lengths of galvanized steel without interruption.

Key Differences Between Batch and Continuous Galvanizing

Batch galvanizing involves immersing steel components in a molten zinc bath individually or in small groups, making it ideal for custom or small-scale orders with complex shapes, while continuous galvanizing uses a moving steel strip passed through a molten zinc bath for high-volume production. Batch galvanizing offers superior coating thickness control and better adhesion, suitable for heavier or irregularly shaped items, whereas continuous galvanizing excels in uniform, thinner coatings with higher throughput and cost efficiency. The choice between the two depends on factors such as production scale, coating precision, item geometry, and project timelines.

Material Suitability: Batch vs Continuous Galvanizing

Batch galvanizing suits heavy-duty or irregularly shaped steel components requiring thicker zinc coatings, making it ideal for structural beams and large fittings. Continuous galvanizing works best for thin, flat steel strips or coils, providing consistent, uniform coatings ideal for mass-produced sheet metals used in automotive and appliance manufacturing. Your choice depends on the material shape and production volume, with batch processes offering flexibility and continuous methods delivering efficiency for standardized steel products.

Coating Thickness and Quality Comparison

Batch galvanizing typically produces a thicker zinc coating, ranging from 50 to 150 microns, offering superior corrosion resistance for heavy-duty applications. Continuous galvanizing, with coating thickness generally between 20 to 50 microns, provides a uniform and smooth finish optimized for high-volume steel products like automotive panels. The quality of batch galvanizing excels in durability and protection, while continuous galvanizing excels in consistent surface appearance and efficiency in mass production.

Corrosion Resistance Performance

Batch galvanizing provides superior corrosion resistance due to thicker, more uniform zinc coatings applied in controlled, small-scale processes. Continuous galvanizing delivers consistent yet thinner zinc layers, offering good corrosion protection mainly suited for high-volume steel sheet production. Your choice depends on required durability, with batch galvanizing ideal for heavy-duty applications exposed to harsh environments.

Cost Factors for Each Galvanizing Method

Batch galvanizing typically incurs higher labor and energy costs due to its intermittent nature and manual handling, making it suitable for smaller, custom projects. Continuous galvanizing offers lower per-unit costs by maintaining efficiency through automation and steady production runs, ideal for large-scale steel processing. Your choice depends on project size and budget, balancing upfront expenses against long-term cost efficiency.

Typical Applications of Batch and Continuous Galvanizing

Batch galvanizing is typically used for small quantities of irregular-shaped or large components such as structural steel, pipes, and automotive parts, where heavy coating and corrosion resistance are required. Continuous galvanizing is ideal for large-scale production of flat steel products like sheets, coils, and strips used in the construction, appliance, and automotive industries due to its high-speed processing and uniform coating thickness. Both methods provide durable zinc coatings but are selected based on production volume and product geometry.

Choosing the Right Galvanizing Process

Batch galvanizing involves immersing individual steel components in a molten zinc bath, offering superior coating thickness and corrosion resistance ideal for complex or large parts. Continuous galvanizing passes steel coils through a molten zinc bath, providing a uniform, high-speed coating suited for high-volume production of flat steel products. Selecting the right galvanizing process depends on part geometry, production volume, and required coating properties to ensure optimal durability and cost-efficiency.

batch galvanizing vs continuous galvanizing Infographic

libmatt.com

libmatt.com