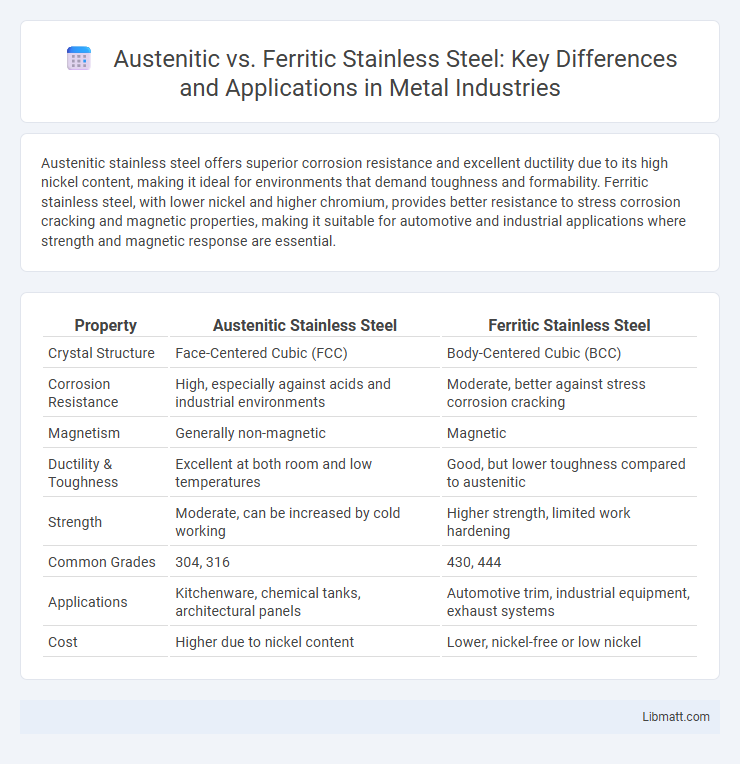

Austenitic stainless steel offers superior corrosion resistance and excellent ductility due to its high nickel content, making it ideal for environments that demand toughness and formability. Ferritic stainless steel, with lower nickel and higher chromium, provides better resistance to stress corrosion cracking and magnetic properties, making it suitable for automotive and industrial applications where strength and magnetic response are essential.

Table of Comparison

| Property | Austenitic Stainless Steel | Ferritic Stainless Steel |

|---|---|---|

| Crystal Structure | Face-Centered Cubic (FCC) | Body-Centered Cubic (BCC) |

| Corrosion Resistance | High, especially against acids and industrial environments | Moderate, better against stress corrosion cracking |

| Magnetism | Generally non-magnetic | Magnetic |

| Ductility & Toughness | Excellent at both room and low temperatures | Good, but lower toughness compared to austenitic |

| Strength | Moderate, can be increased by cold working | Higher strength, limited work hardening |

| Common Grades | 304, 316 | 430, 444 |

| Applications | Kitchenware, chemical tanks, architectural panels | Automotive trim, industrial equipment, exhaust systems |

| Cost | Higher due to nickel content | Lower, nickel-free or low nickel |

Introduction to Austenitic and Ferritic Stainless Steel

Austenitic stainless steel contains high levels of chromium and nickel, offering excellent corrosion resistance and good formability, making it ideal for cookware and medical instruments. Ferritic stainless steel, composed primarily of chromium with low carbon content and little or no nickel, provides superior resistance to stress corrosion cracking and magnetic properties, suitable for automotive and industrial applications. Understanding these key attributes helps you select the right stainless steel type for durability and performance in specific environments.

Chemical Composition Differences

Austenitic stainless steel contains high levels of chromium (16-26%) and nickel (6-22%) with low carbon content, providing excellent corrosion resistance and ductility. Ferritic stainless steel has lower nickel content, typically less than 0.5%, but a chromium content ranging from 10.5% to 27%, resulting in magnetic properties and better stress corrosion cracking resistance. Your choice depends on the chemical composition's impact on mechanical properties and environmental suitability.

Microstructure Comparison

Austenitic stainless steel features a face-centered cubic (FCC) microstructure, providing excellent toughness, corrosion resistance, and non-magnetic properties, making it ideal for diverse applications. Ferritic stainless steel has a body-centered cubic (BCC) microstructure, offering superior resistance to stress corrosion cracking and magnetic properties, but generally lower ductility compared to austenitic types. Understanding these microstructural differences helps you select the appropriate stainless steel grade based on mechanical and environmental requirements.

Mechanical Properties Overview

Austenitic stainless steel offers superior ductility and toughness, with tensile strength typically ranging from 515 to 827 MPa and excellent resistance to impact and fatigue. Ferritic stainless steel provides higher yield strength, often around 450 to 700 MPa, with good resistance to stress corrosion cracking but lower ductility compared to austenitic grades. The mechanical properties of austenitic grades make them ideal for applications requiring high formability, while ferritic stainless steels are preferred for their strength and magnetic properties.

Corrosion Resistance Performance

Austenitic stainless steel exhibits superior corrosion resistance due to its higher chromium and nickel content, which enhances its ability to form a stable passive oxide layer that protects against oxidation and chemical exposure. Ferritic stainless steel, while less resistant to corrosion, performs well in mildly corrosive environments and demonstrates better resistance to stress corrosion cracking and chloride-induced corrosion compared to martensitic grades. The choice between the two depends on the specific environmental conditions, with austenitic grades preferred in highly corrosive and acidic settings.

Magnetic Properties Distinction

Austenitic stainless steel is generally non-magnetic due to its face-centered cubic (FCC) crystal structure, making it ideal for applications where magnetic interference must be minimized. Ferritic stainless steel, with its body-centered cubic (BCC) structure, exhibits magnetic properties, providing better performance in environments requiring magnetic response or attraction. Understanding the magnetic distinction between these stainless steel types helps you select the right material for specific industrial or household uses.

Common Grades and Applications

Austenitic stainless steel grades such as 304 and 316 are widely used in chemical processing, food equipment, and architectural applications due to their excellent corrosion resistance and high ductility. Ferritic stainless steel grades like 430 and 446 are commonly found in automotive parts, kitchen utensils, and industrial equipment where moderate corrosion resistance and good formability are required. Both types serve specific industrial needs, with austenitic preferred for harsh environments and ferritic for cost-effective, less corrosive conditions.

Weldability and Fabrication

Austenitic stainless steel offers superior weldability due to its high ductility and low carbon content, reducing the risk of cracking during fabrication processes. Ferritic stainless steel, while magnetic and less expensive, poses challenges such as grain growth and brittleness at high temperatures, making welding more difficult and requiring controlled heat input. Choosing the right steel for your project depends on the balance between weldability needs and fabrication constraints.

Cost and Availability Factors

Austenitic stainless steel typically costs more than ferritic stainless steel due to higher nickel content and more complex production processes. Ferritic stainless steel offers greater availability and affordability, making it ideal for applications where budget constraints are critical. Understanding these cost and availability factors helps you select the most suitable stainless steel type for your project requirements.

Choosing the Right Stainless Steel Type

Selecting the appropriate stainless steel type depends on factors like corrosion resistance, mechanical strength, and magnetic properties. Austenitic stainless steel, known for its excellent corrosion resistance and non-magnetic nature, is ideal for chemical processing and food industry applications. Ferritic stainless steel offers good stress corrosion cracking resistance and magnetic properties, making it suitable for automotive parts and industrial equipment requiring moderate corrosion resistance.

Austenitic vs ferritic stainless steel Infographic

libmatt.com

libmatt.com