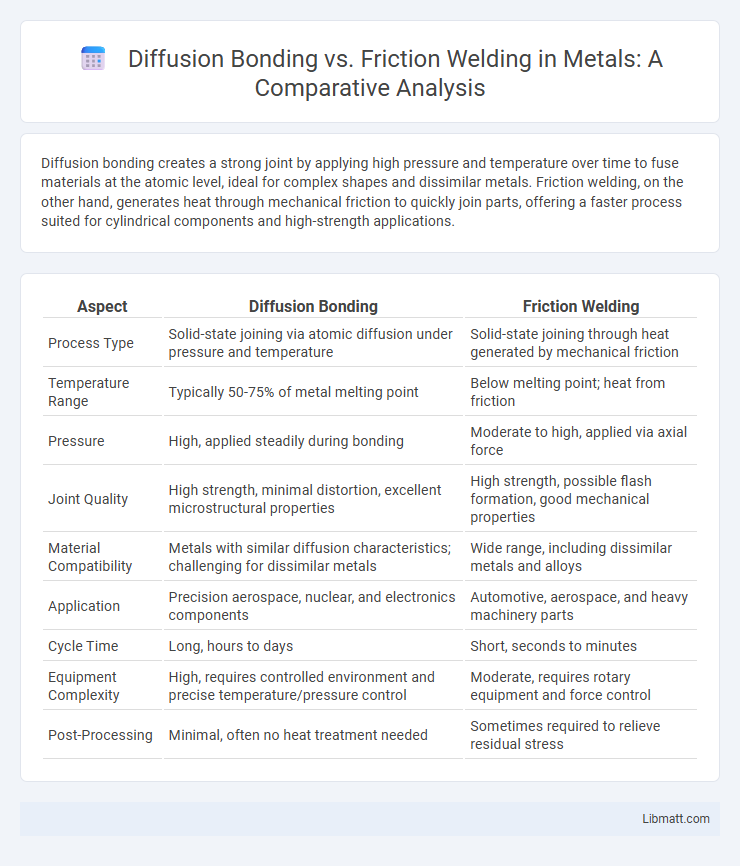

Diffusion bonding creates a strong joint by applying high pressure and temperature over time to fuse materials at the atomic level, ideal for complex shapes and dissimilar metals. Friction welding, on the other hand, generates heat through mechanical friction to quickly join parts, offering a faster process suited for cylindrical components and high-strength applications.

Table of Comparison

| Aspect | Diffusion Bonding | Friction Welding |

|---|---|---|

| Process Type | Solid-state joining via atomic diffusion under pressure and temperature | Solid-state joining through heat generated by mechanical friction |

| Temperature Range | Typically 50-75% of metal melting point | Below melting point; heat from friction |

| Pressure | High, applied steadily during bonding | Moderate to high, applied via axial force |

| Joint Quality | High strength, minimal distortion, excellent microstructural properties | High strength, possible flash formation, good mechanical properties |

| Material Compatibility | Metals with similar diffusion characteristics; challenging for dissimilar metals | Wide range, including dissimilar metals and alloys |

| Application | Precision aerospace, nuclear, and electronics components | Automotive, aerospace, and heavy machinery parts |

| Cycle Time | Long, hours to days | Short, seconds to minutes |

| Equipment Complexity | High, requires controlled environment and precise temperature/pressure control | Moderate, requires rotary equipment and force control |

| Post-Processing | Minimal, often no heat treatment needed | Sometimes required to relieve residual stress |

Introduction to Diffusion Bonding and Friction Welding

Diffusion bonding is a solid-state joining process that relies on high temperature and pressure to enable atomic diffusion between closely mated surfaces, creating a strong metallurgical bond without melting the base materials. Friction welding is a solid-state process that generates heat through mechanical friction between two components, followed by the application of pressure to forge a weld as the material softens but does not melt. Both techniques are valued for producing joints with excellent mechanical properties and minimal distortion, often used for joining difficult-to-weld metals and dissimilar materials.

Fundamental Principles of Each Joining Method

Diffusion bonding relies on solid-state atomic diffusion under high temperature and pressure, causing materials to join at their grain boundaries without melting. Friction welding generates heat through mechanical friction between rotating or moving parts, softening the interface for direct bonding upon rapid cooling. Both methods produce strong, high-integrity joints ideal for aerospace and automotive applications, but diffusion bonding is preferred for delicate materials due to its lower thermal distortion.

Materials Suitable for Diffusion Bonding and Friction Welding

Diffusion bonding is highly effective for joining reactive and refractory materials such as titanium, nickel-based superalloys, and ceramics due to its low-temperature, solid-state process that preserves material properties. Friction welding excels with metals including carbon steels, stainless steels, aluminum alloys, and copper by generating heat through mechanical friction that produces strong, high-integrity joints. Both methods offer distinct advantages tailored to specific material characteristics, influencing their selection based on thermal sensitivity and metallurgical compatibility.

Process Parameters and Requirements

Diffusion bonding requires precise control of temperature, pressure, and holding time to enable atomic diffusion between metal surfaces, typically conducted at temperatures between 50-70% of the metal's melting point under sustained pressure. Friction welding relies on rotational speed, friction force, and forge pressure to generate heat through mechanical friction, rapidly joining materials without melting. Your choice depends on the specific material properties and application, with diffusion bonding ideal for complex assemblies needing minimal distortion and friction welding suited for high-strength, rapid production joints.

Strength and Quality of Joints

Diffusion bonding produces joints with superior metallurgical integrity, resulting in high strength and minimal defects due to the atomic diffusion process at elevated temperatures under pressure. Friction welding generates strong joints by plastic deformation and heat from friction, offering excellent mechanical properties and rapid bonding but occasionally exhibits microstructural inconsistencies. Both methods deliver high-quality joints, yet diffusion bonding excels in creating defect-free interfaces ideal for complex or dissimilar material assemblies.

Applications in Industry

Diffusion bonding is widely used in aerospace and nuclear industries due to its ability to join complex, high-strength materials without melting, making it ideal for turbine blades and heat exchangers. Friction welding finds extensive application in automotive and manufacturing sectors, where rapid, strong joints are required for components like drive shafts and chassis parts. Understanding these industrial applications can help you select the most efficient joining process for your manufacturing needs.

Advantages and Limitations

Diffusion bonding offers advantages such as producing high-strength, defect-free joints without melting the base materials, making it ideal for joining dissimilar metals and complex geometries with minimal distortion. However, it requires long processing times and precise surface preparation, limiting its use in high-volume production. Friction welding provides faster bonding with excellent mechanical properties and minimal post-processing, but it is generally limited to simpler geometries and similar materials, which may restrict Your application choices.

Cost Analysis and Economic Considerations

Diffusion bonding typically incurs higher initial costs due to specialized equipment and longer processing times, while friction welding offers cost efficiency through faster cycle times and minimal consumable use. Your choice impacts long-term economic considerations, as diffusion bonding can yield superior joint properties that reduce maintenance costs, whereas friction welding provides a balance of strength and affordability ideal for high-volume production. Evaluating material compatibility, part complexity, and production scale is crucial for optimizing cost-effectiveness between these two advanced joining methods.

Recent Innovations and Research Trends

Recent innovations in diffusion bonding emphasize nanoscale interface engineering and advanced vacuum environments to enhance joint strength and reduce bonding times. Friction welding research trends focus on adaptive control systems and hybrid techniques combining ultrasonic energy to improve weld quality and process efficiency. Both methods benefit from real-time monitoring and AI-driven predictive maintenance to optimize industrial applications.

Selecting the Right Method for Your Project

Selecting the right method between diffusion bonding and friction welding depends on the materials involved, joint strength requirements, and production scale. Diffusion bonding excels in creating high-integrity joints for complex or dissimilar materials without melting, ideal for aerospace and electronics applications. Friction welding offers faster cycle times and is cost-effective for high-volume production of components with similar metals, commonly used in automotive and manufacturing industries.

Diffusion bonding vs friction welding Infographic

libmatt.com

libmatt.com