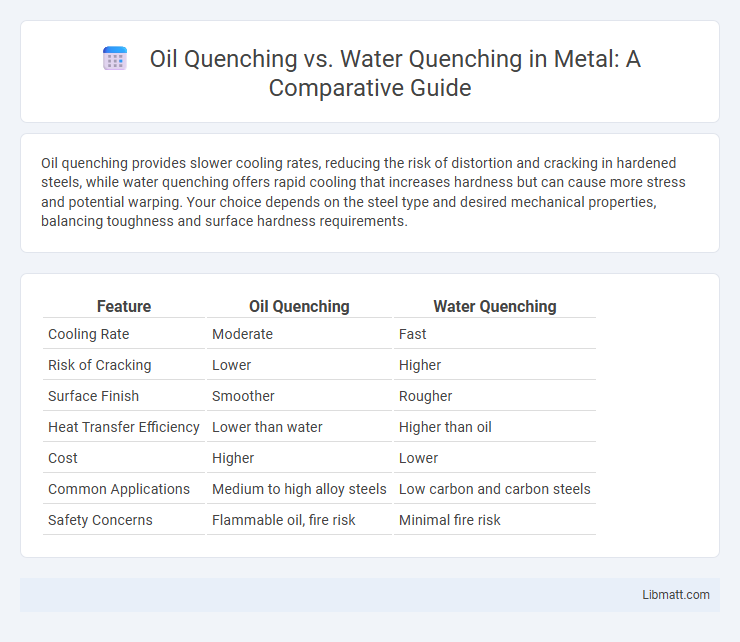

Oil quenching provides slower cooling rates, reducing the risk of distortion and cracking in hardened steels, while water quenching offers rapid cooling that increases hardness but can cause more stress and potential warping. Your choice depends on the steel type and desired mechanical properties, balancing toughness and surface hardness requirements.

Table of Comparison

| Feature | Oil Quenching | Water Quenching |

|---|---|---|

| Cooling Rate | Moderate | Fast |

| Risk of Cracking | Lower | Higher |

| Surface Finish | Smoother | Rougher |

| Heat Transfer Efficiency | Lower than water | Higher than oil |

| Cost | Higher | Lower |

| Common Applications | Medium to high alloy steels | Low carbon and carbon steels |

| Safety Concerns | Flammable oil, fire risk | Minimal fire risk |

Introduction to Quenching Methods

Oil quenching and water quenching are essential heat treatment processes used to rapidly cool metals, influencing their hardness and mechanical properties. Oil quenching provides slower cooling rates compared to water quenching, reducing the risk of cracking in steels with complex geometries. You should choose the quenching method based on the alloy composition and desired balance between hardness and toughness.

Basic Principles of Oil Quenching

Oil quenching involves immersing heated metal into oil, which cools the material more slowly than water, reducing the risk of distortion and cracking. The slower cooling rate allows for better control over hardness and toughness, making it ideal for parts requiring high strength and wear resistance. Your choice of oil or water quenching depends on the desired balance between cooling speed and material properties.

Fundamentals of Water Quenching

Water quenching rapidly cools metal by immersing it in water, creating a high cooling rate that enhances hardness and strength through the formation of martensite. This process involves heat transfer via convection and vaporization, with the evaporative cooling effect playing a critical role in temperature reduction. Your choice depends on desired mechanical properties, where water quenching provides faster cooling compared to oil quenching, but may increase the risk of distortion or cracking.

Key Differences Between Oil and Water Quenching

Oil quenching involves cooling heated metal in oil, providing slower cooling rates that reduce the risk of cracking and distortion, while water quenching offers rapid cooling for increased hardness but higher susceptibility to thermal stress. The choice between oil and water quenching depends on the material composition and desired mechanical properties, with oil quenching favored for alloy steels and water quenching commonly used for carbon steels. Differences in heat transfer coefficients and cooling medium viscosity critically influence microstructural transformations and final toughness.

Material Compatibility with Each Method

Oil quenching is ideal for medium to high carbon steels due to its slower cooling rate, which reduces the risk of cracking and distortion, preserving the material's structural integrity. Water quenching provides rapid cooling suitable for low carbon and some alloy steels, but it can cause higher thermal stress, leading to increased chances of warping or cracking in sensitive materials. Understanding your material's composition helps determine whether oil or water quenching will optimize hardness and toughness without compromising durability.

Impact on Mechanical Properties and Microstructure

Oil quenching results in slower cooling rates than water quenching, producing more uniform microstructures with reduced internal stresses and minimal cracking risk. Water quenching leads to rapid cooling, increasing hardness and strength but can cause distortion and higher residual stresses due to the formation of martensite. Your choice between oil and water quenching directly affects the mechanical properties such as toughness, hardness, and ductility, impacting the performance of heat-treated components.

Advantages of Oil Quenching

Oil quenching offers superior cooling control compared to water quenching, reducing the risk of distortion and cracking in heat-treated metals. The slower cooling rate preserves material toughness and minimizes residual stresses, enhancing the structural integrity of components. Its effectiveness in hardening steels with complex geometries makes oil quenching a preferred choice for critical applications requiring balanced hardness and ductility.

Advantages of Water Quenching

Water quenching offers rapid cooling rates that enhance the hardness and strength of steel by promoting martensitic transformation more effectively than oil quenching. Its cost-effectiveness and wide availability make it an ideal choice for large-scale industrial heat treatment processes. If your goal is to achieve maximum hardness quickly, water quenching delivers superior results due to its higher thermal conductivity compared to oil.

Common Applications and Industry Use Cases

Oil quenching is commonly employed in the automotive and aerospace industries for hardening medium to high carbon steels, providing uniform cooling and reducing the risk of cracking in complex parts like gears and shafts. Water quenching is preferred in tool manufacturing and heavy machinery sectors due to its rapid cooling rate, ideal for high-carbon steels requiring maximum hardness, such as cutting tools and drill bits. The selection between oil and water quenching directly impacts microstructure and mechanical properties, influencing performance in applications demanding wear resistance or toughness.

Safety Considerations and Environmental Impact

Oil quenching poses higher fire hazards due to the flammability of oil, requiring stringent safety measures, while water quenching is less prone to fire but may cause severe steam explosions if not carefully controlled. Environmental impact of oil quenching includes potential soil and water contamination from spent quenching oils, necessitating proper disposal and treatment, whereas water quenching generates wastewater that may contain hazardous metals and requires filtration before release. Your choice between oil and water quenching must weigh these safety risks and ecological effects to ensure compliance and workplace safety.

Oil quenching vs water quenching Infographic

libmatt.com

libmatt.com