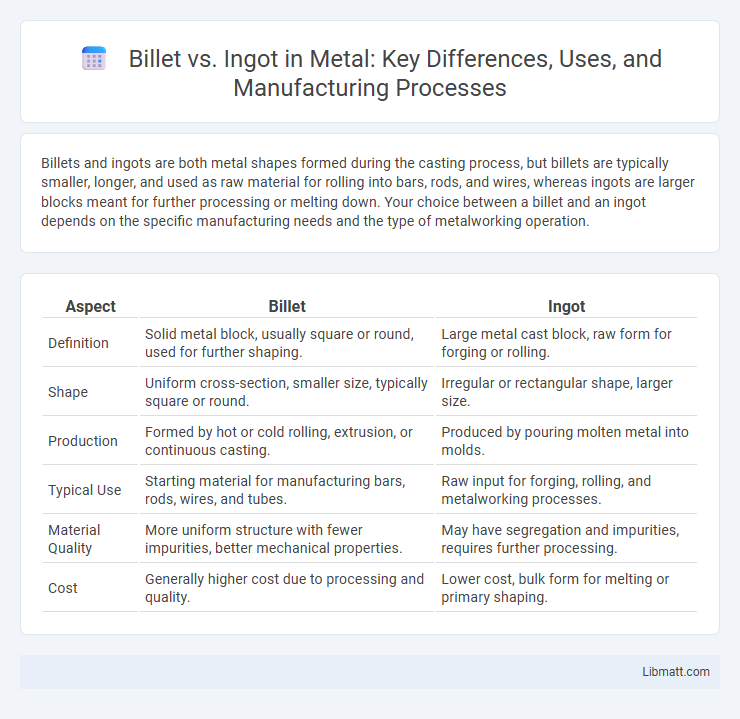

Billets and ingots are both metal shapes formed during the casting process, but billets are typically smaller, longer, and used as raw material for rolling into bars, rods, and wires, whereas ingots are larger blocks meant for further processing or melting down. Your choice between a billet and an ingot depends on the specific manufacturing needs and the type of metalworking operation.

Table of Comparison

| Aspect | Billet | Ingot |

|---|---|---|

| Definition | Solid metal block, usually square or round, used for further shaping. | Large metal cast block, raw form for forging or rolling. |

| Shape | Uniform cross-section, smaller size, typically square or round. | Irregular or rectangular shape, larger size. |

| Production | Formed by hot or cold rolling, extrusion, or continuous casting. | Produced by pouring molten metal into molds. |

| Typical Use | Starting material for manufacturing bars, rods, wires, and tubes. | Raw input for forging, rolling, and metalworking processes. |

| Material Quality | More uniform structure with fewer impurities, better mechanical properties. | May have segregation and impurities, requires further processing. |

| Cost | Generally higher cost due to processing and quality. | Lower cost, bulk form for melting or primary shaping. |

Introduction to Billets and Ingots

Billets and ingots are key intermediate metal products used in manufacturing and metalworking industries. Billets are semi-finished metal products with a smaller cross-sectional area, typically cylindrical or square, designed for further processing into bars, rods, or wire. Ingots are larger, cast blocks of metal formed by solidifying molten metal in molds, serving as raw material for rolling or forging into billets or other shapes.

Defining Billets: Key Characteristics

Billets are semi-finished metal products characterized by a solid, cylindrical or square cross-section with dimensions typically ranging from 30mm to 150mm. They are produced through continuous casting or extrusion processes and serve as the raw material for manufacturing bars, rods, and wire. Billets exhibit uniform chemical composition and enhanced mechanical properties suitable for subsequent hot rolling or forging operations.

Defining Ingots: Key Characteristics

Ingots are large, pure metal blocks cast during the initial stage of metal processing, typically rectangular or cylindrical in shape, designed for ease of storage and transport. They exhibit uniform chemical composition and solidified grain structure, making them ideal for subsequent melting, rolling, or forging operations. Their key characteristics include standardized dimensions, high purity levels, and consistent mechanical properties essential for industrial manufacturing.

Differences in Manufacturing Processes

Billets are produced through continuous casting or hot rolling, involving the extrusion of molten metal into small, typically square or circular bars that are easier to handle and process further. Ingots are formed by pouring molten metal into molds and allowing it to cool and solidify into large, block-shaped masses requiring subsequent hot or cold working to achieve desired shapes. The billet manufacturing process emphasizes uniformity and fine grain structure for superior mechanical properties, while ingot casting prioritizes large-scale metal production with slower cooling rates leading to coarse grain structures.

Applications of Billets in Industry

Billets find extensive applications in the manufacturing and automotive industries due to their uniform cross-section and superior mechanical properties. They are commonly used for producing shafts, rods, and bars through processes like hot rolling, forging, and extrusion, ensuring high strength and durability in structural components. The steel and aluminum billets serve as essential raw materials for fabricating machine parts, pipelines, and construction materials that demand precision and reliability.

Applications of Ingots in Industry

Ingots are widely used in industries such as automotive manufacturing, aerospace, and metal fabrication due to their homogeneous composition and ease of further processing. Their large, standardized shapes allow for efficient melting and remelting in foundries to produce alloys and castings tailored to specific engineering needs. Your industrial operations benefit from the consistent quality and structural integrity provided by ingots, enabling reliable production of high-performance metal components.

Physical and Chemical Properties Comparison

Billets and ingots differ primarily in their physical dimensions and internal structures, with billets being smaller and more uniform, which enhances their mechanical properties such as tensile strength and ductility. Chemically, both billets and ingots typically share the same alloy composition; however, billets undergo processes like hot rolling that refine grain structure, improving corrosion resistance and overall material performance. Understanding these distinctions helps you select the appropriate form for precise applications requiring optimized strength and durability.

Advantages and Disadvantages: Billet vs Ingot

Billets offer advantages such as uniform grain structure and superior mechanical properties due to their smaller cross-section and controlled cooling, making them ideal for precision manufacturing. Ingots, while more cost-effective for large-scale production, often have issues like segregation and variable grain size, leading to potential weaknesses in the final product. Your choice depends on balancing these factors, prioritizing quality and consistency with billets or cost-efficiency and volume with ingots.

Cost and Market Considerations

Billets typically cost less than ingots due to their smaller size and easier handling, making them ideal for manufacturers focused on reducing raw material expenses. Ingot prices tend to be higher because of the additional processing required to cast and cool larger metal blocks, which impacts market demand and supply. Your choice between billet and ingot depends on production scale and budget constraints, balancing cost efficiency with material availability in the metals market.

Choosing Between Billet and Ingot: Key Factors

Choosing between billet and ingot depends on factors such as desired material properties, manufacturing process, and end-use application. Billets, typically smaller and more uniform, enable better mechanical properties and precision in processes like forging and extrusion. Ingots, larger and less refined, are suited for casting and subsequent shaping steps where size and volume are priorities over surface finish and structural uniformity.

Billet vs Ingot Infographic

libmatt.com

libmatt.com