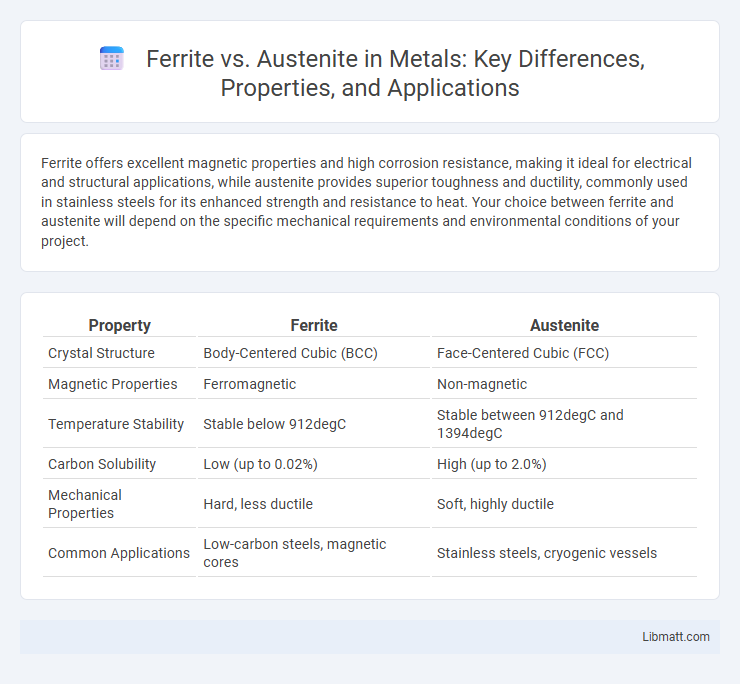

Ferrite offers excellent magnetic properties and high corrosion resistance, making it ideal for electrical and structural applications, while austenite provides superior toughness and ductility, commonly used in stainless steels for its enhanced strength and resistance to heat. Your choice between ferrite and austenite will depend on the specific mechanical requirements and environmental conditions of your project.

Table of Comparison

| Property | Ferrite | Austenite |

|---|---|---|

| Crystal Structure | Body-Centered Cubic (BCC) | Face-Centered Cubic (FCC) |

| Magnetic Properties | Ferromagnetic | Non-magnetic |

| Temperature Stability | Stable below 912degC | Stable between 912degC and 1394degC |

| Carbon Solubility | Low (up to 0.02%) | High (up to 2.0%) |

| Mechanical Properties | Hard, less ductile | Soft, highly ductile |

| Common Applications | Low-carbon steels, magnetic cores | Stainless steels, cryogenic vessels |

Introduction to Ferrite and Austenite

Ferrite and Austenite are two primary phases of iron found in steel, each with distinct crystal structures and properties. Ferrite exhibits a body-centered cubic (BCC) structure, offering high magnetic permeability and excellent ductility at room temperature, while Austenite has a face-centered cubic (FCC) structure that enables greater toughness and the ability to absorb more carbon. Understanding the differences between Ferrite and Austenite helps you select the most suitable steel variant for applications requiring specific strength, corrosion resistance, or machinability.

Crystal Structure Differences

Ferrite features a body-centered cubic (BCC) crystal structure, offering high magnetic permeability and lower density, while Austenite has a face-centered cubic (FCC) structure that enhances ductility and toughness. The BCC arrangement in Ferrite results in fewer slip systems, making it less malleable compared to the FCC lattice of Austenite, which provides more slip planes for deformation. Your choice between Ferrite and Austenite directly impacts mechanical properties due to these fundamental crystal structure differences.

Chemical Composition Comparison

Ferrite primarily consists of a body-centered cubic (BCC) structure with low carbon content, typically less than 0.02%, and high iron concentration, making it magnetic and ductile. Austenite features a face-centered cubic (FCC) structure with higher carbon content, usually ranging from 0.8% to 2.0%, and contains more nickel and manganese to stabilize its non-magnetic, tougher phase. Understanding these chemical composition differences helps you select the appropriate stainless steel grade for corrosion resistance and mechanical properties.

Mechanical Properties Overview

Ferrite exhibits lower tensile strength but higher ductility and magnetic properties compared to austenite, making it suitable for applications requiring formability and magnetic response. Austenite offers superior toughness, excellent corrosion resistance, and greater tensile strength due to its face-centered cubic (FCC) crystal structure, enhancing performance at cryogenic temperatures. The mechanical properties of ferrite and austenite differ significantly because ferrite has a body-centered cubic (BCC) structure that limits its strength but improves malleability, while austenite's FCC structure allows for increased strain hardening and impact toughness.

Magnetic Properties Contrasted

Ferrite exhibits strong ferromagnetic properties due to its body-centered cubic (BCC) crystal structure, making it highly responsive to magnetic fields and ideal for electromagnetic applications. Austenite, with its face-centered cubic (FCC) structure, is generally non-magnetic, limiting its use in magnetic devices but providing superior corrosion resistance and toughness. Understanding the contrasting magnetic behaviors of ferrite and austenite helps you select the appropriate steel phase for applications requiring specific magnetic responses.

Corrosion Resistance in Ferrite and Austenite

Ferrite stainless steels exhibit moderate corrosion resistance due to their high chromium content but are generally less resistant to pitting and crevice corrosion compared to austenite grades. Austenitic stainless steels, containing higher amounts of nickel and molybdenum, offer superior corrosion resistance in harsh environments, including resistance to chlorides and acidic conditions. Your choice between ferrite and austenite should consider the specific corrosive environment and the required durability for optimal performance.

Applications of Ferritic and Austenitic Steels

Ferritic steels, known for their magnetic properties and excellent corrosion resistance, are widely used in automotive exhaust systems, industrial equipment, and kitchen appliances due to their high strength and cost-effectiveness. Austenitic steels, characterized by superior corrosion resistance and excellent toughness at cryogenic temperatures, find applications in chemical processing, medical devices, and food processing industries where hygiene and durability are critical. Your choice between ferritic and austenitic steels depends on the specific environmental conditions and mechanical requirements of your project.

Weldability and Fabrication Considerations

Ferrite offers superior weldability due to its lower carbon content and stable microstructure, reducing the risk of cracking during fabrication processes. Austenite, while providing excellent ductility and toughness, requires careful control of cooling rates and filler materials to prevent issues such as hot cracking and sensitization. Your choice between ferrite and austenite should consider the specific welding techniques and fabrication requirements of your project to ensure structural integrity.

Cost and Availability Analysis

Ferrite steels generally offer lower cost and higher availability due to their simpler iron-carbon microstructure and widespread production compared to austenite steels, which require more alloying elements like nickel and manganese, increasing expenses. Ferritic grades are commonly used in construction and automotive industries where budget constraints are critical, while austenitic steels, known for corrosion resistance and toughness, are more expensive but essential in chemical processing and medical applications. Understanding the cost-benefit balance of ferrite versus austenite helps you select materials that meet both performance requirements and budget limitations.

Choosing Between Ferrite and Austenite

Choosing between ferrite and austenite depends on the specific application requirements for mechanical strength, corrosion resistance, and magnetic properties. Ferrite, a body-centered cubic (BCC) iron phase, offers good magnetic permeability and ductility but lower toughness compared to austenite. Austenite, with a face-centered cubic (FCC) structure, provides superior corrosion resistance, higher toughness, and non-magnetic properties, making it ideal for cryogenic and highly corrosive environments.

Ferrite vs Austenite Infographic

libmatt.com

libmatt.com