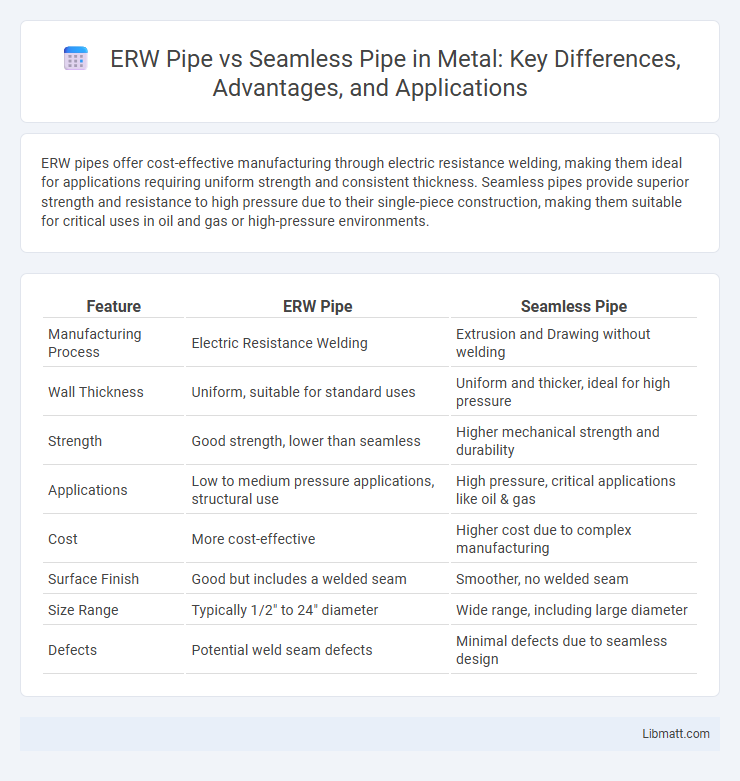

ERW pipes offer cost-effective manufacturing through electric resistance welding, making them ideal for applications requiring uniform strength and consistent thickness. Seamless pipes provide superior strength and resistance to high pressure due to their single-piece construction, making them suitable for critical uses in oil and gas or high-pressure environments.

Table of Comparison

| Feature | ERW Pipe | Seamless Pipe |

|---|---|---|

| Manufacturing Process | Electric Resistance Welding | Extrusion and Drawing without welding |

| Wall Thickness | Uniform, suitable for standard uses | Uniform and thicker, ideal for high pressure |

| Strength | Good strength, lower than seamless | Higher mechanical strength and durability |

| Applications | Low to medium pressure applications, structural use | High pressure, critical applications like oil & gas |

| Cost | More cost-effective | Higher cost due to complex manufacturing |

| Surface Finish | Good but includes a welded seam | Smoother, no welded seam |

| Size Range | Typically 1/2" to 24" diameter | Wide range, including large diameter |

| Defects | Potential weld seam defects | Minimal defects due to seamless design |

Introduction to ERW and Seamless Pipes

ERW pipes are manufactured by electric resistance welding, where steel strips are formed into a cylindrical shape and welded longitudinally, resulting in cost-effective and uniform pipes ideal for water, gas, and construction applications. Seamless pipes are produced by piercing a solid billet and expanding it into a hollow tube, offering superior strength, high-pressure resistance, and suitability for critical industries such as oil and gas, petrochemical, and power generation. Both ERW and seamless pipes vary in manufacturing technology, mechanical properties, and typical usage environments based on their design and structural integrity.

Understanding ERW Pipe: Definition and Manufacturing

ERW pipe, or Electric Resistance Welded pipe, is produced by rolling metal and welding it longitudinally across its length using electric resistance heating. This manufacturing process provides precise dimensions and a smooth surface, making ERW pipes suitable for low to medium pressure applications in industries such as oil and gas, water transportation, and structural purposes. Compared to seamless pipes, ERW pipes offer cost efficiency and consistent wall thickness but are less capable of withstanding high pressure or extreme conditions due to the weld seam.

What Is Seamless Pipe? Production and Features

Seamless pipe is manufactured by extruding a solid billet to create a hollow tube without any welds, resulting in a uniform, smooth surface and consistent strength. The production process involves piercing a heated steel billet and elongating it into a seamless cylindrical shape, which enhances its resistance to high pressure and temperature. These pipes provide superior mechanical properties, making them ideal for applications requiring high durability, such as oil and gas pipelines, boilers, and structural components.

Key Differences Between ERW and Seamless Pipes

ERW (Electric Resistance Welded) pipes are manufactured by rolling and welding steel plates, resulting in a seam along the length, unlike seamless pipes which are formed by extruding a solid billet to create a hollow tube without any seams. Seamless pipes offer superior strength and resistance to pressure due to their uniform composition, making them ideal for high-pressure applications, while ERW pipes provide economical solutions for lower to medium pressure environments. The choice between ERW and seamless pipes depends on factors like application pressure, cost, and mechanical properties required in industries such as oil and gas, construction, and automotive.

Strength and Durability Comparison

ERW (Electric Resistance Welded) pipes exhibit strong weld seams but may have slightly lower strength compared to seamless pipes, which are manufactured from a single solid billet, providing superior uniformity and higher tensile strength. Seamless pipes demonstrate enhanced durability and resistance to high pressure and extreme conditions, making them suitable for critical applications such as oil and gas pipelines. The absence of weld seam in seamless pipes reduces the risk of failure under stress, contributing to their overall superior performance in demanding environments.

Cost Analysis: ERW Pipe vs Seamless Pipe

ERW pipes generally offer a lower material cost compared to seamless pipes due to their manufacturing process, which involves rolling and welding steel strips. Seamless pipes, produced by extrusion or rotary piercing without a weld, often incur higher costs because of their complex production and enhanced strength properties. For applications requiring high pressure or critical mechanical performance, the higher expense of seamless pipes may be justified by their superior structural integrity.

Typical Applications for ERW Pipes

ERW (Electric Resistance Welded) pipes are commonly used in structural applications, water and gas transportation, and low to medium pressure systems due to their uniform thickness and cost-effectiveness. These pipes are ideal for applications such as scaffolding, mechanical structural tubing, and conduit piping where strength and durability are essential. You can rely on ERW pipes for consistent performance in manufacturing, automotive, and furniture industries, emphasizing their versatility over seamless pipes in specific industrial scenarios.

Common Uses of Seamless Pipes

Seamless pipes are widely used in high-pressure applications such as oil and gas transportation, petrochemical industries, and power plants due to their superior strength and resistance to pressure. These pipes are ideal for critical environments like boiler tubes, hydraulic systems, and structural applications where durability and reliability are paramount. Their uniform thickness and absence of weld seams make them preferable for high-temperature and high-stress conditions compared to ERW pipes.

Advantages and Disadvantages of Each Pipe Type

ERW pipe offers cost efficiency and uniform thickness due to its electric resistance welding process, making it ideal for low-pressure applications and structural uses, though it may have slightly lower strength compared to seamless pipes. Seamless pipe boasts superior strength and resistance to high pressure and temperature, as it is manufactured without a weld seam, enhancing reliability for critical applications like oil and gas transport, but it typically comes at a higher price and with longer lead times. Your choice depends on balancing budget constraints with the required mechanical properties and application demands.

How to Choose Between ERW and Seamless Pipes

Choosing between ERW and seamless pipes depends on your project's pressure requirements and budget constraints. ERW pipes are cost-effective and suitable for low to medium pressure applications, while seamless pipes offer superior strength and reliability for high-pressure environments. Assess your specific needs for durability, corrosion resistance, and precision to determine which pipe type best supports your operational goals.

ERW pipe vs seamless pipe Infographic

libmatt.com

libmatt.com